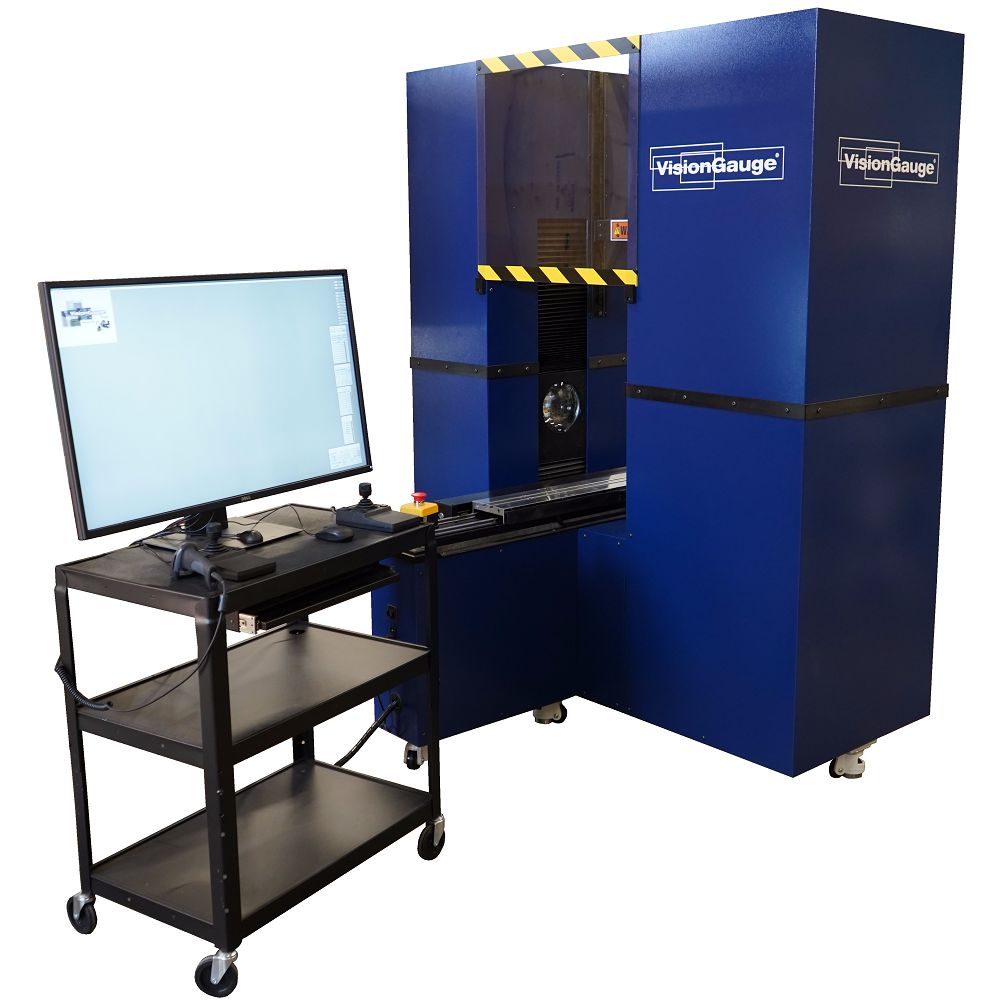

VisionGauge® 600 Series

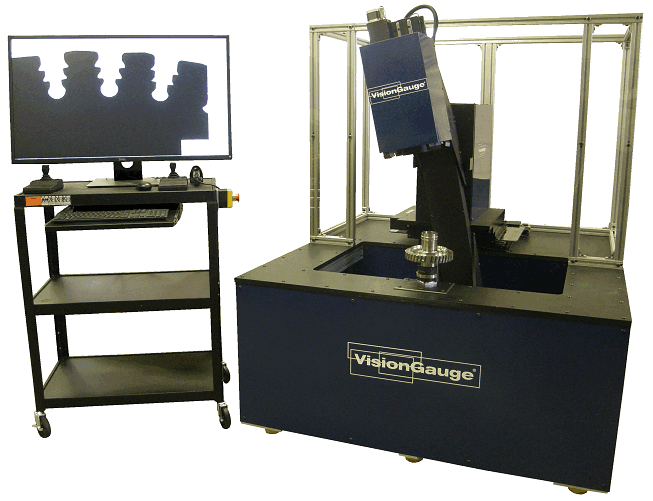

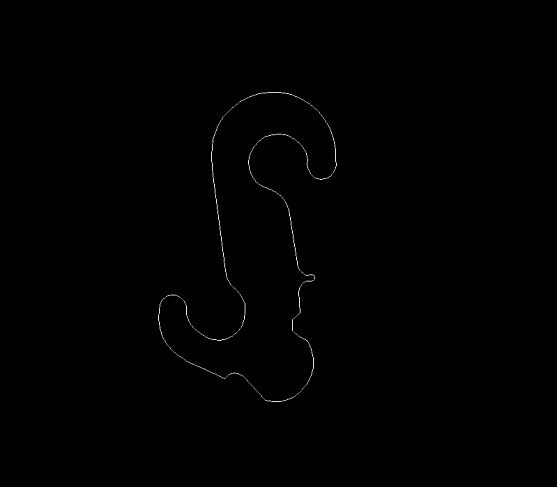

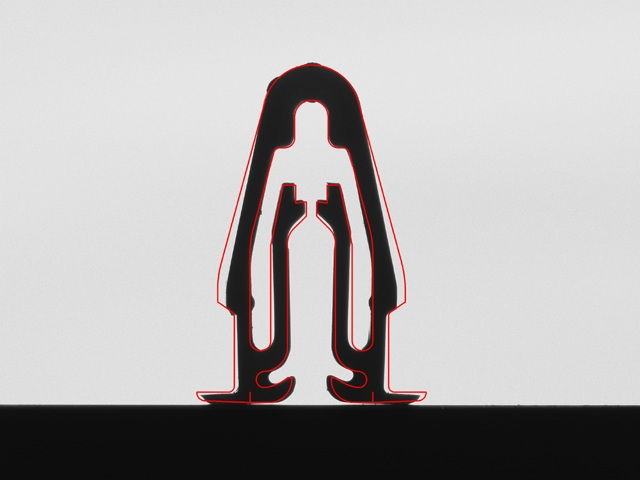

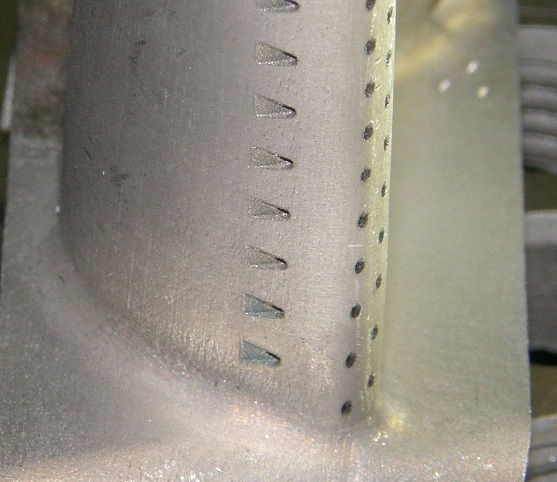

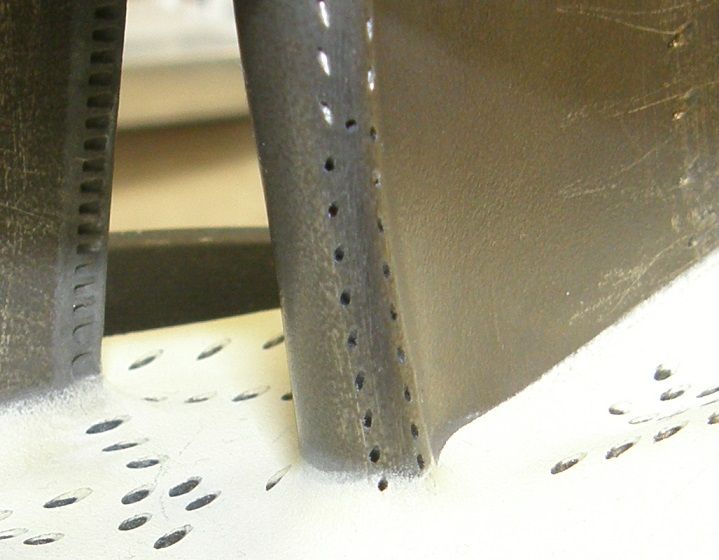

The 600 Series VisionGauge® inspection and measurement system is designed first and foremost to inspect and measure turned and rotationally symmetrical parts, such as:

- Screws,

- Bolts,

- Rivets,

- Shafts,

- Other turned or formed parts…

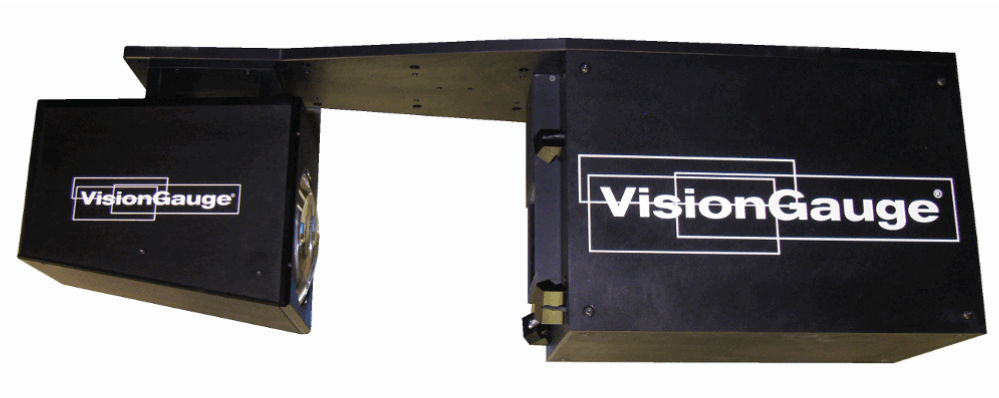

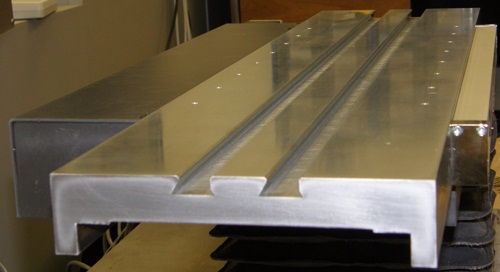

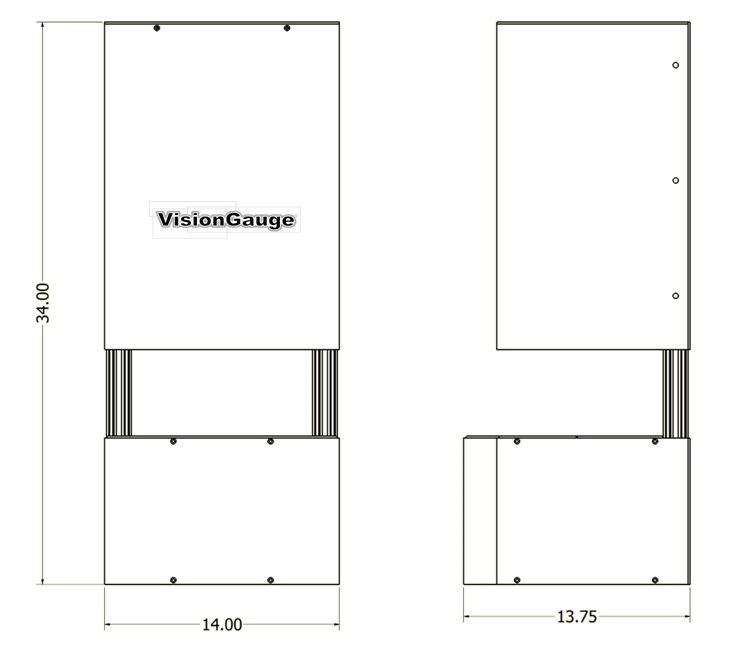

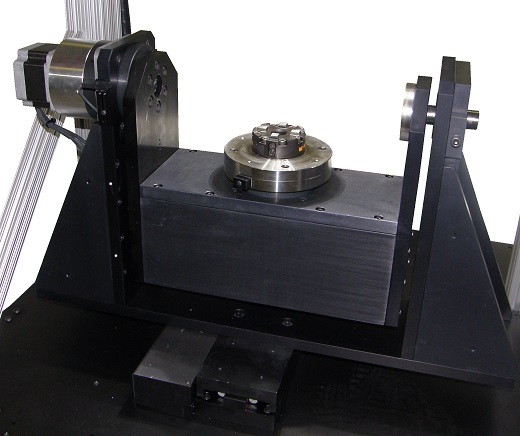

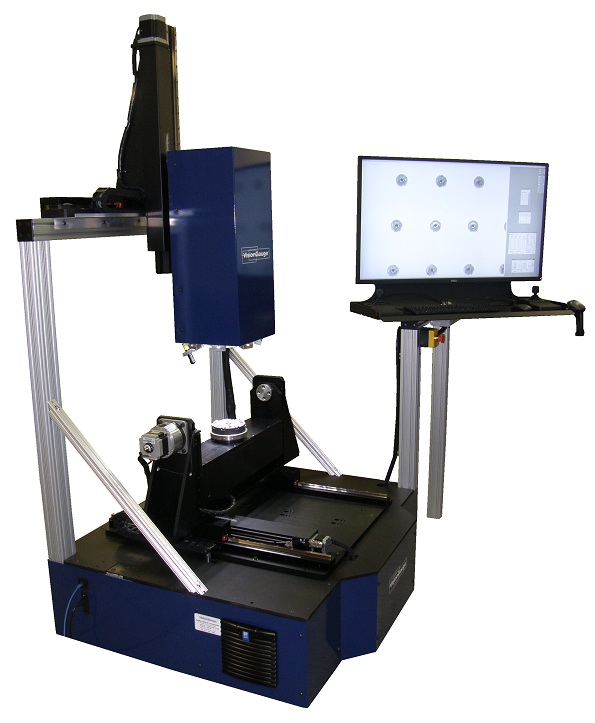

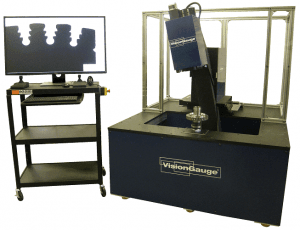

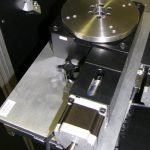

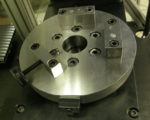

On the 600 Series VisionGauge® system, the part is mounted vertically and the system has two motorized encoded axes: one for part rotation and another for vertical movement (i.e. to move up and down the length of the part).

The system is used across a wide range of industries, including:

- Medical Device manufacturing

- Aerospace

- Fastener industry

- Automotive

- Etc.

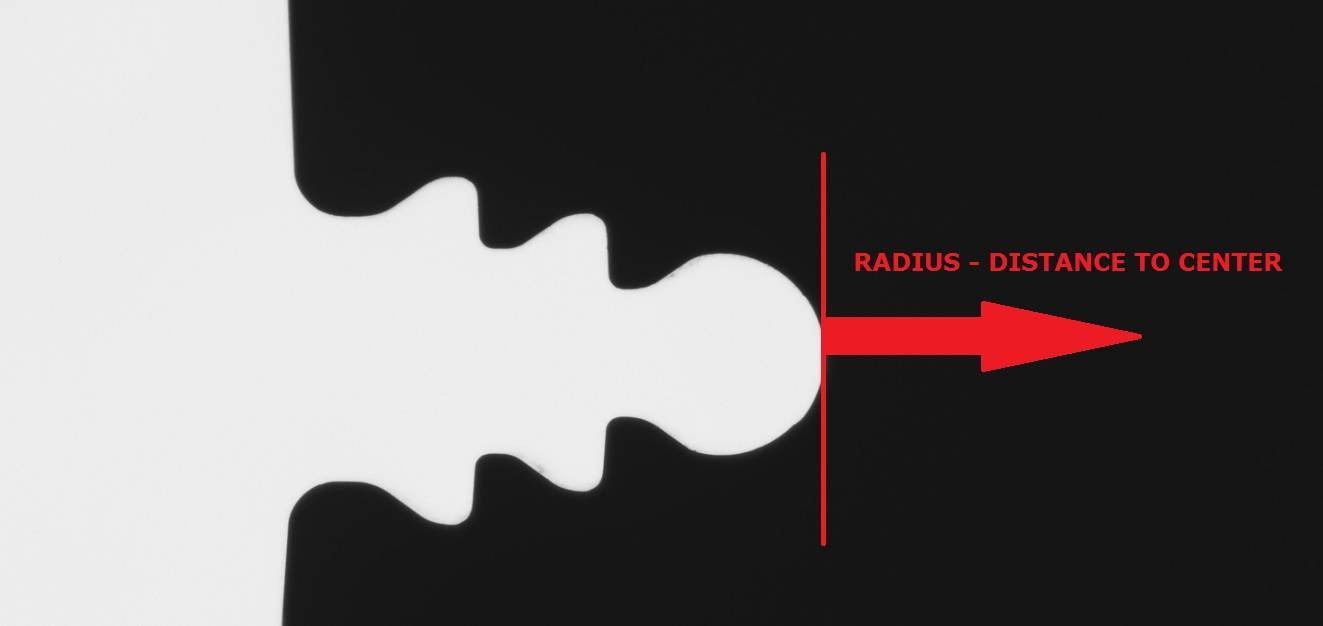

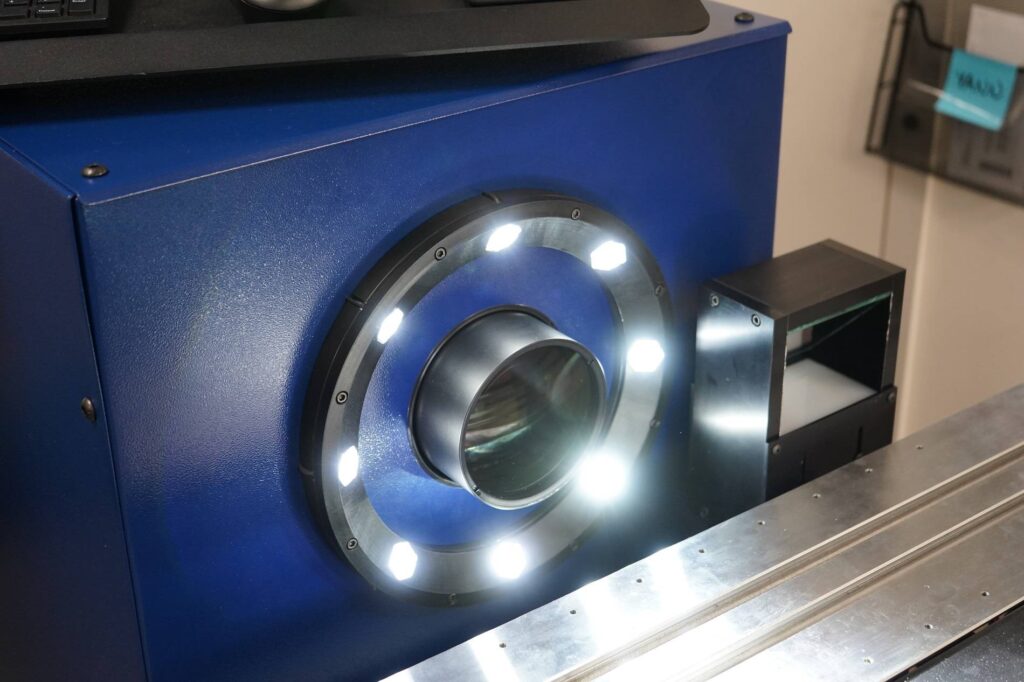

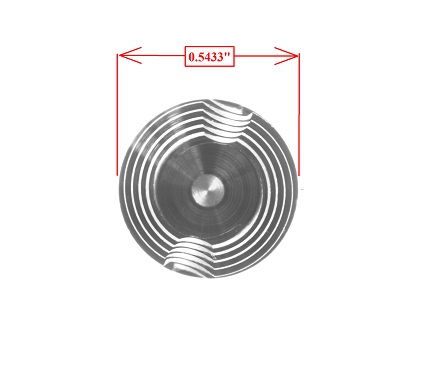

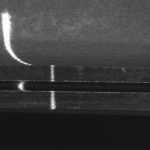

It has ultra-bright all-LED programmable and computer-controlled illumination, both transmitted (i.e. back illumination) to verify the part’s outline, and reflected (i.e. front illumination) to inspect and measure surface features.

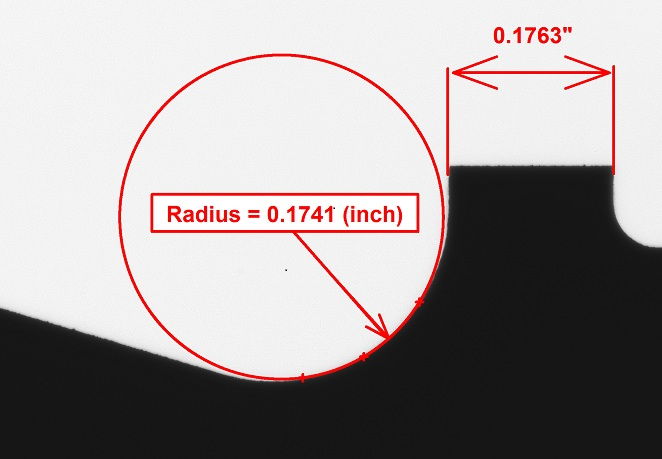

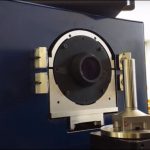

It has a very high-resolution optical system, with a large depth-of-field and a long working distance and produces an optical accuracy better than +/-0.00015″ (i.e. 4 μm). It produces very crisp and clear, high-contrast, high-resolution images.

600 Series Features

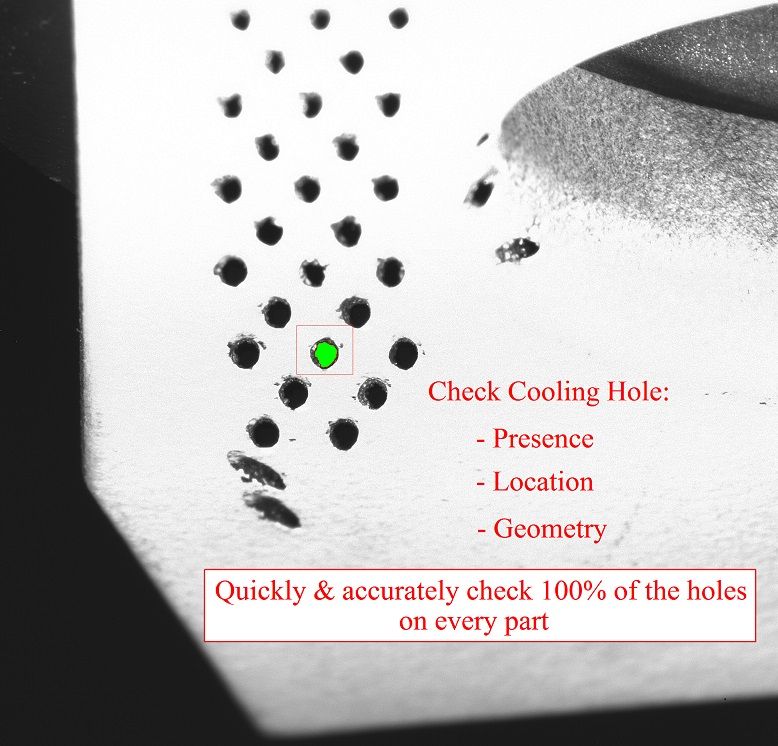

The 600 Series system has all of VisionGauge®’s advanced software capabilities, including:

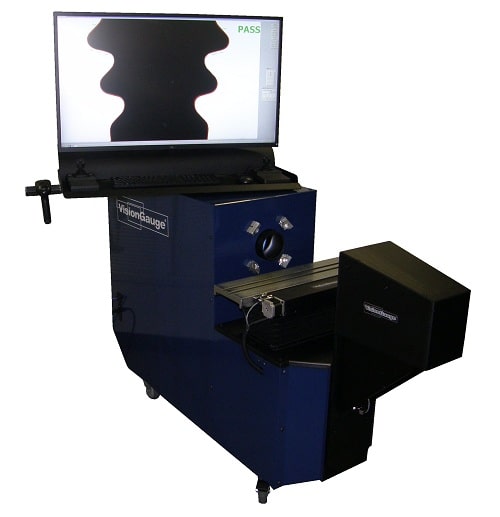

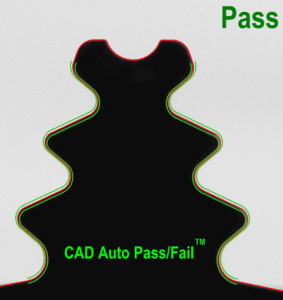

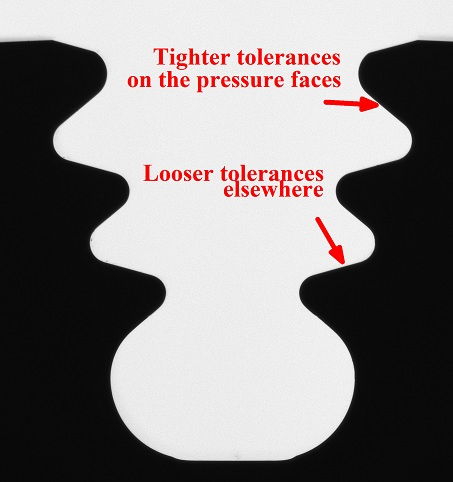

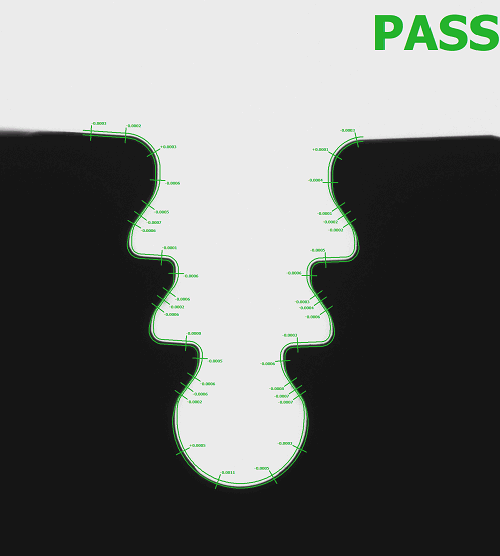

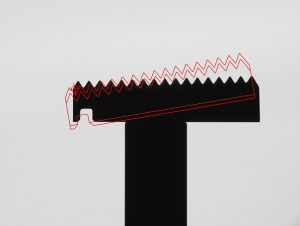

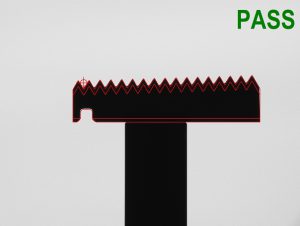

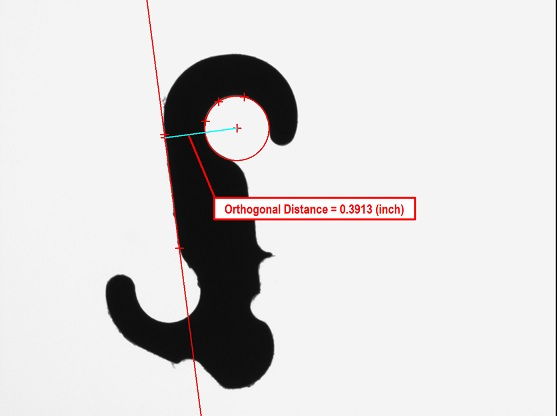

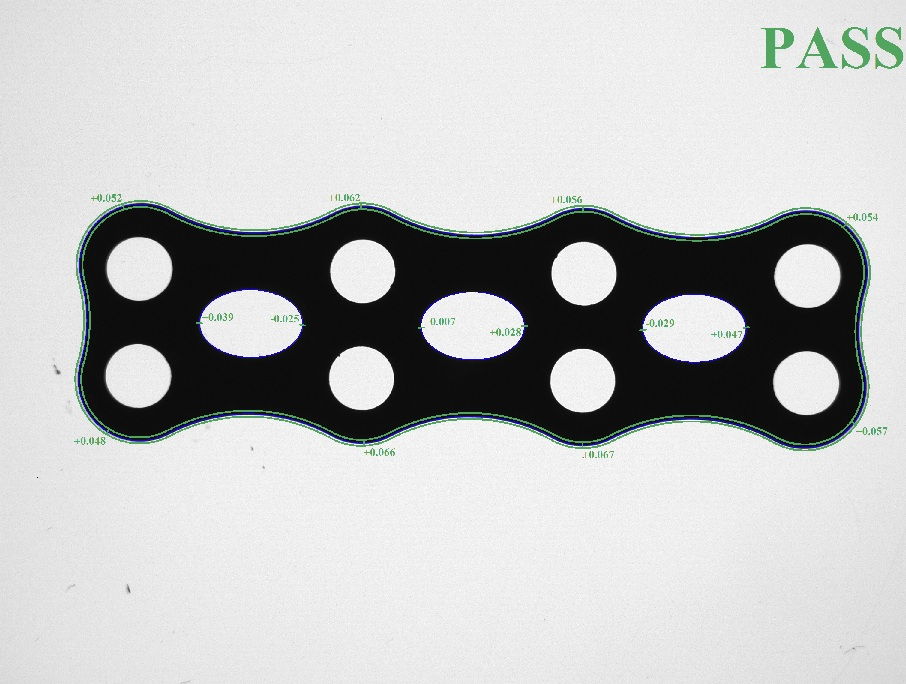

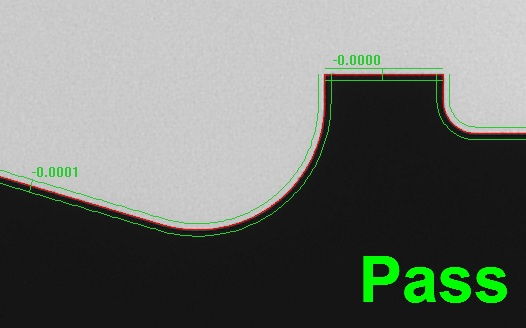

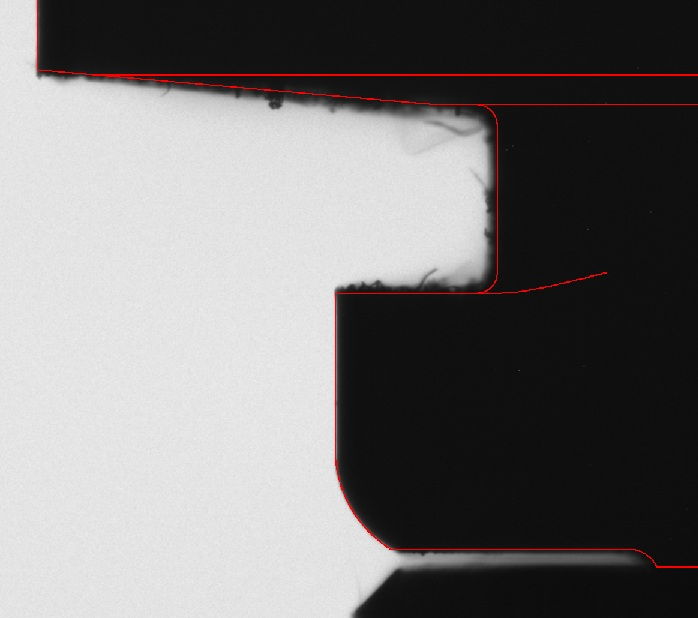

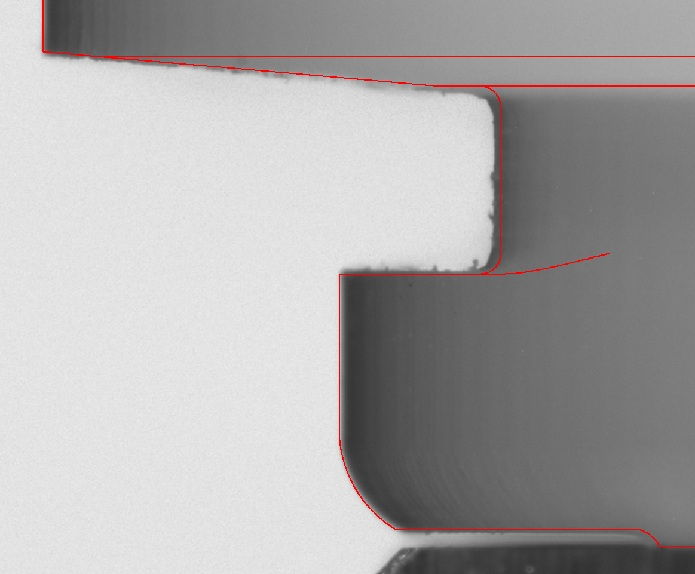

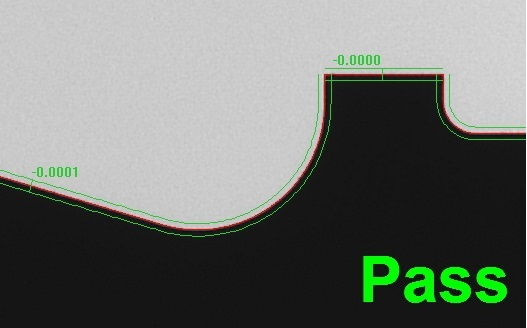

1. CAD Auto-Align™: This patented groundbreaking tool automatically aligns a CAD overlay to a specific part, feature or datum(s) during inspection. Within seconds, it produces repeatable results without any operator supervision, drastically reducing inspection time and improving measurement accuracy.

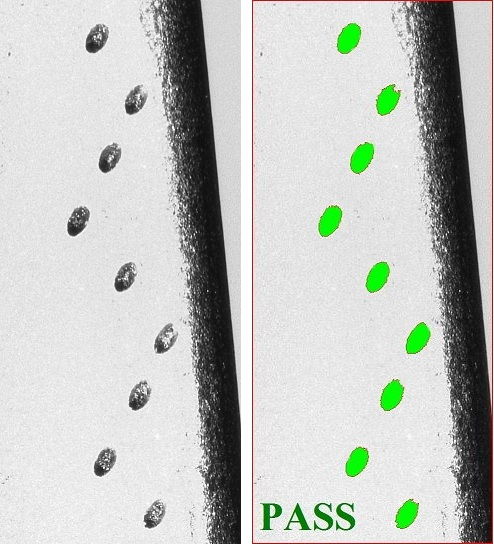

2. CAD Auto-Pass/Fail™ technology: The CAD Auto-Pass/Fail™ tool automatically determines whether a part is within tolerance and measures the deviation from nominal in real time and with great accuracy.

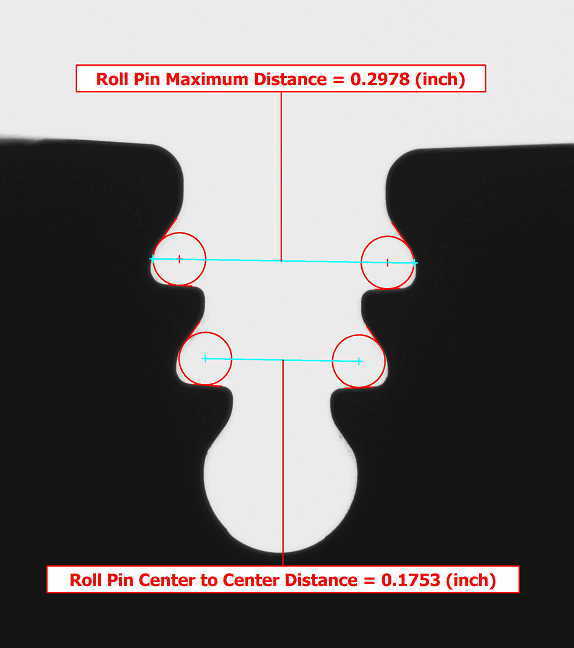

3. Tooth Checker™: Designed to check parts with teeth, the patented Tooth Checker™ tool automatically locates the crests and roots in the inspected part’s teeth or threads. It determines, to very high accuracy, if parts fall within their specified tolerance band.

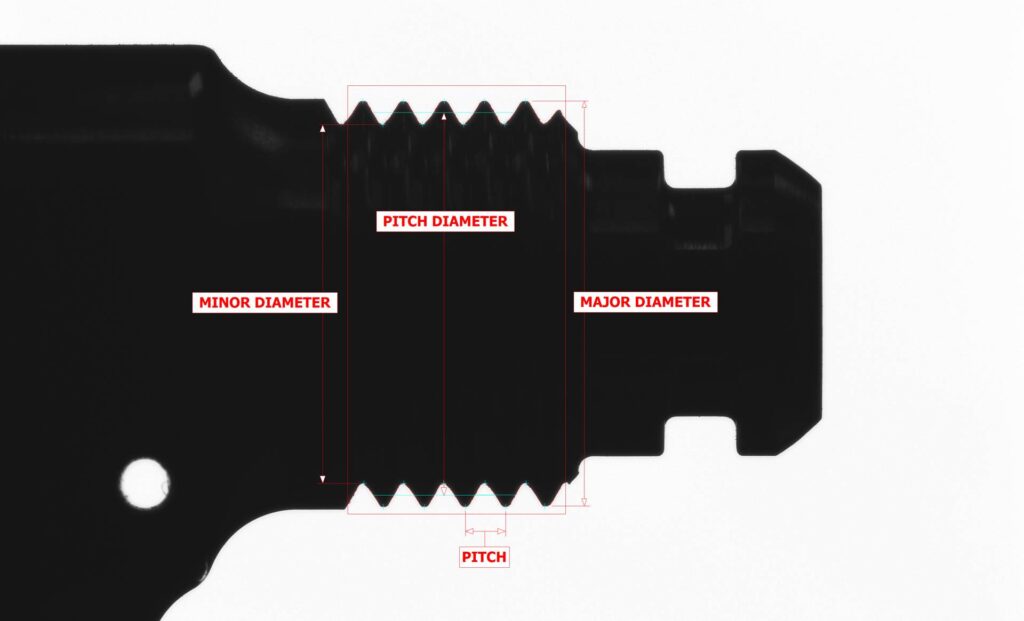

4. VisionGauge® Thread Measurement Tools: VisionGauge®’s advanced thread inspection tools perform automatic measurements on a wide range of parts with threads (not just limited to screws!). These non-contact measurements ensure that the related geometric aspects defining the threads conform to their manufactured specifications.

The 600 Series VisionGauge® system contains the entire set of powerful VisionGauge® measurement tools. It can measure:

- Roundness,

- Runout,

- Coaxiality,

- Cylindricity,

- Parallelism,

- …And much more!

Advantages of the 600 Series Inspection and Measurement System

Like all VisionGauge® systems, it can easily be interfaced to external equipment and machinery, such as an automated cell controller a collaborative robot for automated loading and unloading, for full “lights out” operation.

Measure turned parts with optical accuracy better than +/- 0.00015″.

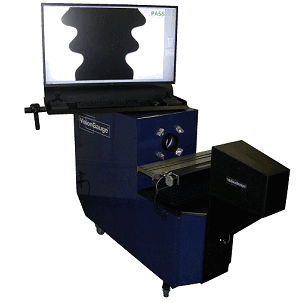

Compact desktop format.

The 600 Series VisionGauge® system is very robust and shop-floor-ready. With its intuitive Windows interface, it’s extremely easy to use.

Optimize Turned Parts Inspection and Measurement with VisionGauge® 600 Series Systems

Contact us with your application requirements, and visit our Applications page for more examples of applications VisionGauge® Inspection & Measurement Systems can solve.