Digital Optical Comparator vs. Traditional Optical Comparator

Optical comparators are innovative tools used throughout manufacturing applications to inspect, measure, and compare the specifications of various manufactured parts. These machines use high-quality lenses and mirrors to magnify a component’s silhouette onto a screen and allow for an in-depth examination, checking for defects and inaccuracies.

Optical comparators are available in both traditional and digital configurations. Manual comparators are straightforward and valuable in smaller applications but lack the efficiency and strength to keep up with large-scale production cost-effectively. These tools can only produce 2D renderings of simple parts one at a time, making them quite labor-intensive.

Instead, more operations are turning to advanced digital optical comparators for streamlined work and enhanced accuracy.

What Are the Benefits of Digital Optical Comparators?

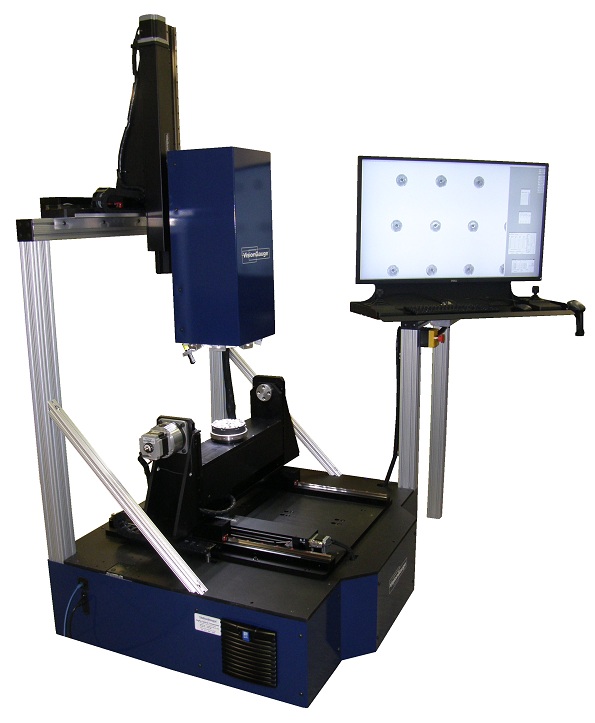

Digital optical comparators allow professionals to obtain precise and dependable measurements of their products, resulting in higher-quality production output. They use high-quality digital cameras, sophisticated software, and unique lighting techniques to analyze simple and complex parts, complete with practical 3D capabilities.

Other benefits of digital optical comparators include:

Accuracy

Digital optical comparators are highly accurate devices delivering precise measurements and comparisons. Using advanced digital image processing and innovative computations, these systems can make corrections to enhance overall image quality. They can correct 2D non-linear distortion while performing other enhancements like sharpening edges and reducing noise to create a high-quality image.

While many traditional tools use templates and overlays, which tend to distort and stretch over time, these machines work with existing CAD plans for precise part comparisons. Digital optical comparator software also features sub-pixel edge detection technology to locate edges between pixels for ultra-precise results with minimal human error.

Usability

Digital tools streamline quality control and inspection procedures. They are quickly installed within various environments, allowing operators to incorporate them easily directly into their operations. Their small footprint optimizes floor space, and their mobility supports fast and efficient inspections throughout your location without needing re-calibrations in-between.

Digital versions use lenses with much larger depths of field, allowing the system to keep everything in focus while conducting inspections. This feature eliminates the need to refocus when continuously analyzing different sections of a specific part. Since this happens automatically, multiple parts can be examined without human participation, reducing labor costs while increasing throughput.

Due to their ease of use and convenience, digital optical comparators are widely used throughout numerous industries, such as:

- Aerospace

- Machining

- Military

- Power

- Energy

- Automotive

- Telecommunications

Automation

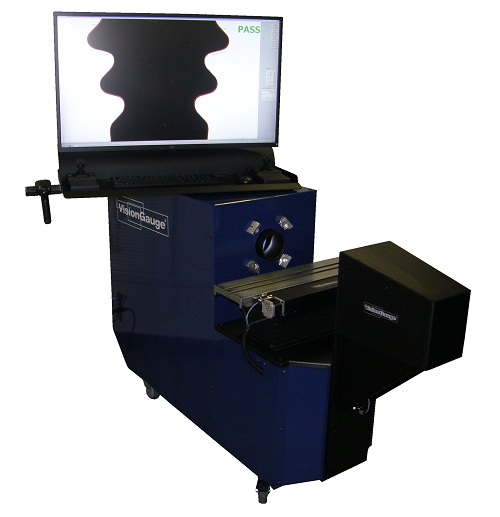

Digital optical comparators are fully automated devices used with intuitive tools, such as the VisionGauge® patented CAD Auto-Pass/Fail™ and CAD Auto-Align™ systems from VISIONx, Inc. These tools make the VisionGauge® Digital Optical Comparator completely independent from operator to operator to increase the dependability and repeatability of the results. Here’s more information regarding these tools:

- CAD Auto-Pass/Fail™: VisionGauge® Digital Optical Comparators deliver automatic reports, charts, statistics, and much more. This tool can determine whether a part is within tolerance, removing any operator subjectivity.

- CAD Auto-Align™: This tool creates the best fit for the CAD by automatically aligning it to the part along the datums. It travels down the length of small and large parts, even across multiple fields-of-view, to collect imaging in different locations and provide information that matters.

Learn More About Digital Optical Comparators From VISIONx

VISIONx specializes in producing state-of-the-art automated imaging, visual inspection, and high-accuracy measurement solutions you can trust. We have created numerous digital optical comparator models capable of improving your site’s specific productivity and performance needs. With our patented VisionGauge® Digital Optical Comparator, you’ll ensure your products are within spec and avoid production flaws more easily than ever.

To learn more about our offerings, check out our selection of comparators or contact us online to connect with a specialist today.