VisionGauge® systems eliminate the need for mylar overlays when conducting inspections and measurements. Our advanced patented technology lets you work directly with your existing CAD data.

Optical comparators play an important role in several industries. They enable the accurate inspection and measurement of different parts and components. These machines provide operators with quantifiable data vital to business operations.

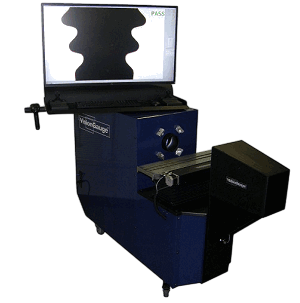

VISIONx, Inc. offers a large selection of advanced digital optical comparators equipped with our proprietary technology. Our devices feature unique systems that fit a wide range of applications. Check out our comparator systems and find which one fits your needs best:

An optical comparator, also known as a profile projector, is a measuring apparatus typically used in the manufacturing industry. Its main function is to inspect, measure, and compare the dimensions of different manufactured parts. Optical comparators use lenses, mirrors, and illumination to project a magnified silhouette of a part. Learn more about what an optical comparator is and how to use it.

VISIONx, Inc. carries a wide selection of digital optical comparators suitable for various applications. Compared to traditional optical comparators, our VisionGauge® systems offer multiple benefits, such as:

VisionGauge® systems eliminate the need for mylar overlays when conducting inspections and measurements. Our advanced patented technology lets you work directly with your existing CAD data.

Our systems are designed with high-accuracy measurements in mind and include high-quality components and advanced VisionGauge® software features such as sub-pixel measurements, Auto-Focus, and more. Our patented CAD Auto-Align™ and CAD Auto Pass/Fail™ tools automatically examine parts and provide data within seconds, ensuring objectivity in all inspections. Learn more about the accuracy of our optical comparators.

Our in-house application engineers will work with you and your team before and after the sale. We can customize and adapt systems to ensure they meet your needs and match specific industry standards.