700 SERIES

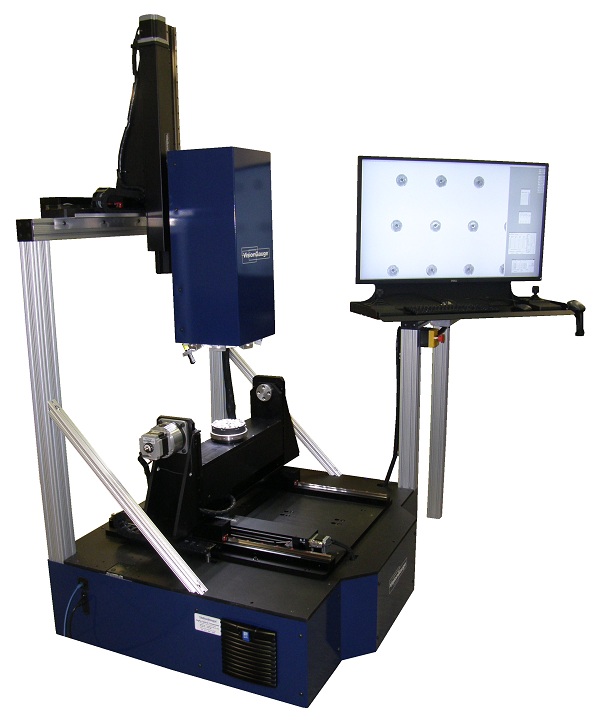

The 700 Series VisionGauge® Digital Optical Comparator 5-axis inspection and measurement systems are the ideal solution for the automatic inspection of parts with complex geometries.

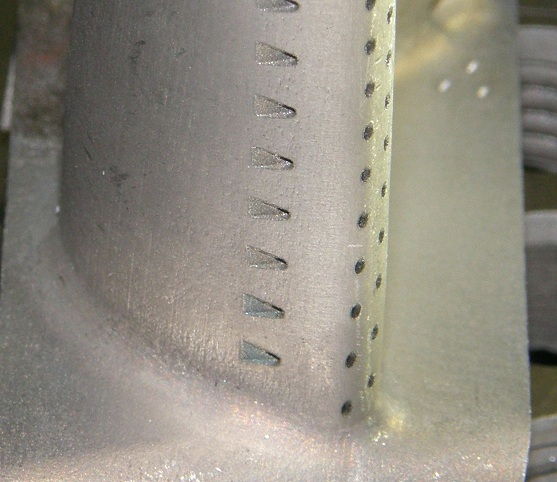

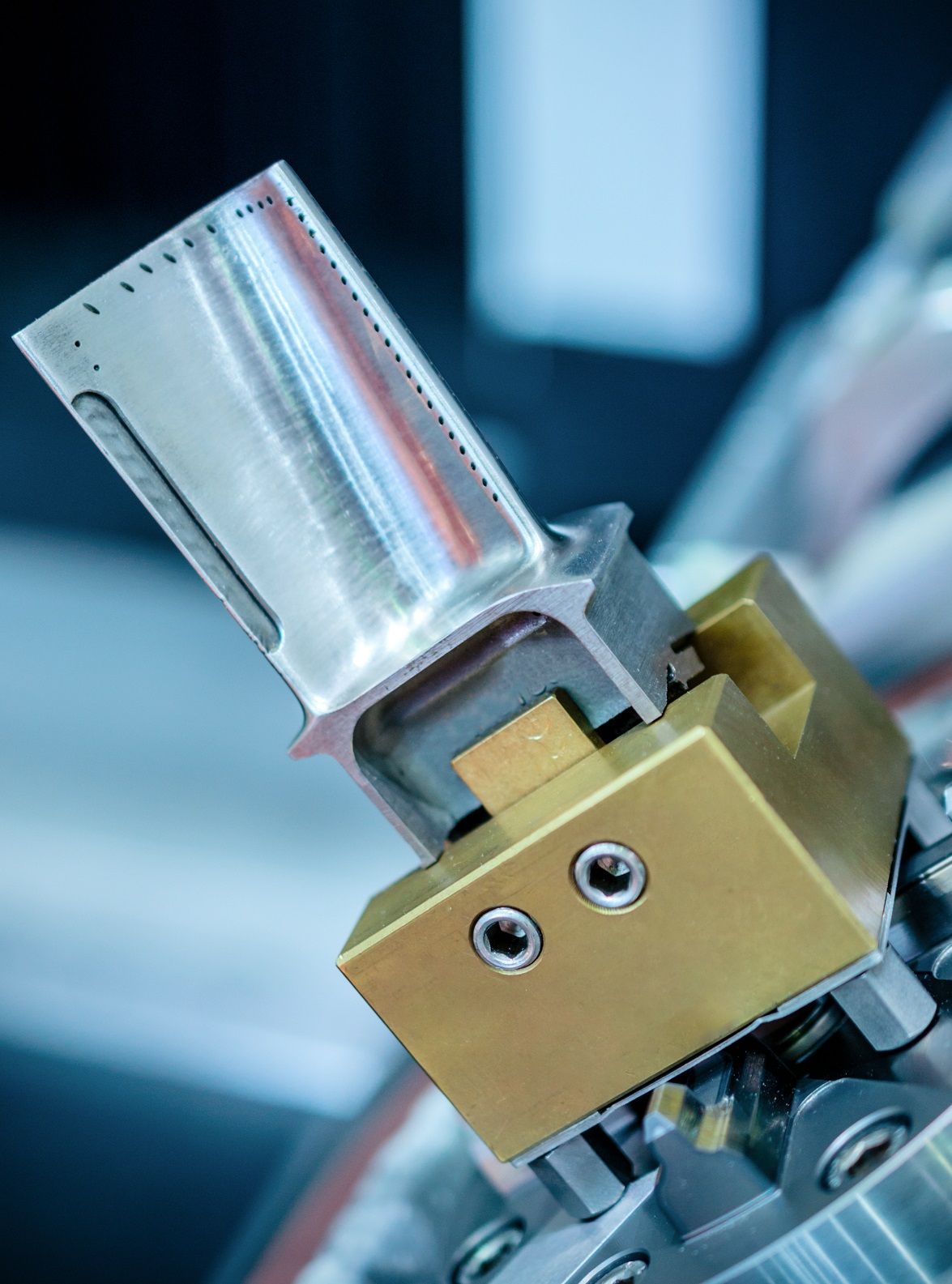

The 700 Series VisionGauge® Digital Optical Comparator is a 5-Axis Inspection and Measurement System that is widely used by manufacturers across a broad range of industries (including aerospace and power generation) to check EDM- and LASER-drilled holes and slots. It is the ideal solution for the automatic inspection of parts with complex geometries. The 5 axes of motion (X, Y, Z, Rotary, Tilt) allow parts to be secured to an industry-standard chuck and positioned accurately to view the part from all sides and angles.

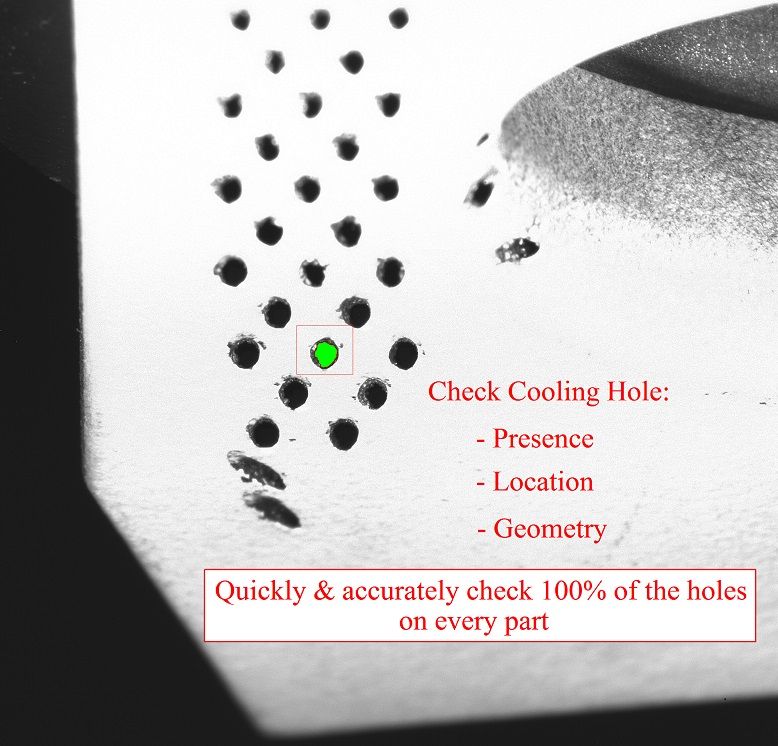

The system is able to automatically verify hole presence and accurately measure hole location. The 700 Series VisionGauge® Digital Optical Comparator is adaptable and supports both round and shaped holes, different surface types with different reflectivity, different viewing angles, etc… VisionGauge® OnLine’s advanced toolset permits programs to locate features with high accuracy and automatically obtain results with a Pass/Fail conclusion based directly on the part’s CAD file specifications. The program can also output the hole offsets, which can then be used to modify EDM drilling programs.

The system provides extremely powerful and innovative software tools for robust component detection, including specialized tools well suited to deal with burrs and splatter. The “Part Reorientation” tool provides the ability to execute full 6-point iterative alignment, and VisionGauge®’s fast and intuitive ‘Operator Review’ mode allows operators to quickly revisit any out-of-tolerances areas. VisionGauge® also supports automatic image and data collection for complete electronic documentation and data-exchange.

The VisionGauge® Digital Optical Comparator is a very cost-effective, perfectly adapted solution for checking EDM- and LASER-drilled holes and slots. It is rapidly becoming the new standard in the industry!

You will find many benefits to using the 700 Series 5-Axis Inspection and Measurement System during the manufacturing process compared to traditional devices or other computerized vision measuring systems. This system goes well-beyond simply producing a report on each part and can significantly enhance the quality of your shop’s inspection operations.

Advantages of incorporating the 700 Series VisionGauge® Digital Optical Comparator into your shop include:

The system comes with an industry-standard chuck mounted on the system’s double-rotary trunnion assembly.

Other mounting systems are also supported.

These systems are ideal for aircraft engine and gas turbine blade cooling holes inspection and measurement.

The 700 Series VisionGauge® Digital Optical Comparator uses innovative tools and software to optimize quality control and reduce operator error. Our solutions have quality features that make comparators like the 700 Series 5-Axis Inspection and Measurement System stand apart from traditional inspection equipment.

Additional features include:

VisionGauge® Digital Optical Comparators are the only industrial vision systems that are fully digital, entirely automated, and outfitted with the groundbreaking CAD Auto-Pass/Fail™ and CAD Auto-Align™ capabilities.

Vision-based inspection systems are cost-effective solutions for maintaining quality control that involve measuring and inspecting images of manufactured parts. They are commonly employed for industrial and manufacturing applications of all types. Modern industrial vision systems have the ability to generate a Pass/Fail report according to the part specifications programmed into the inspection process, alongside more complex insights.

Computer-aided design (CAD) is often the guiding framework for dimensional measurement using vision systems. VisionGauge® machine vision inspection systems, including the 700 Series 5-Axis Inspection and Measurement System, compare a part directly to its CAD/DXF data and automatically produces a Pass/Fail result and detailed measurement report.