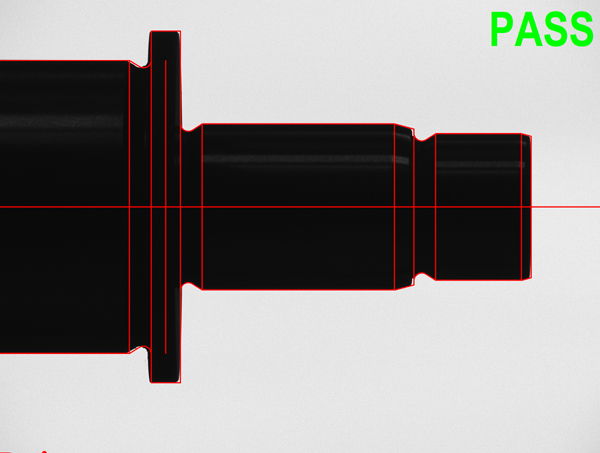

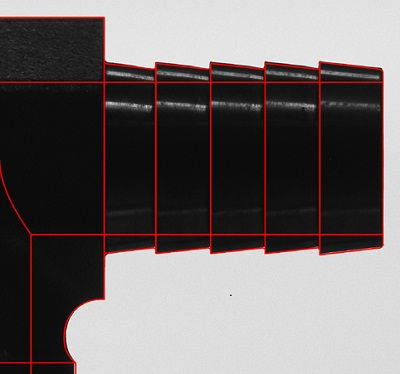

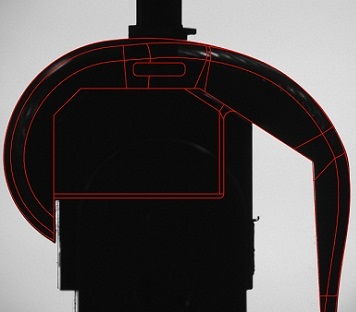

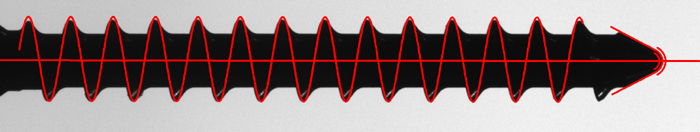

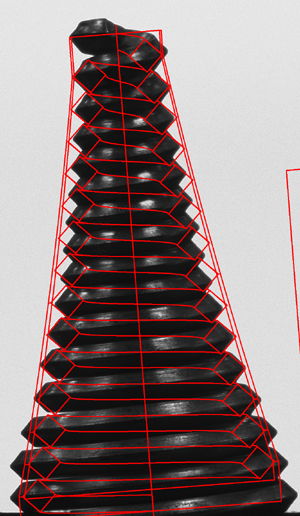

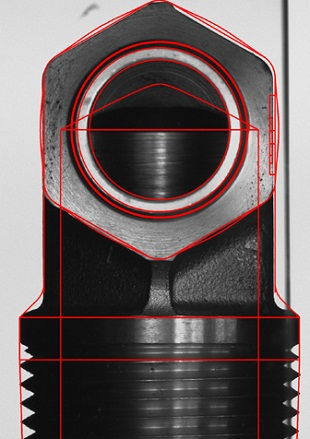

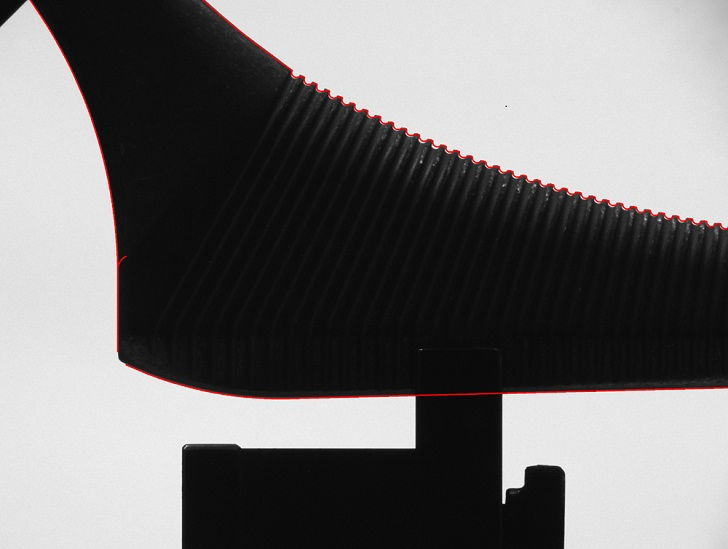

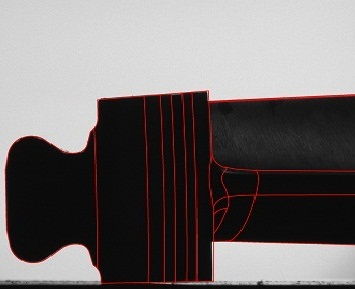

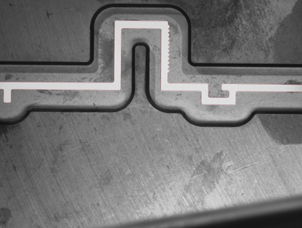

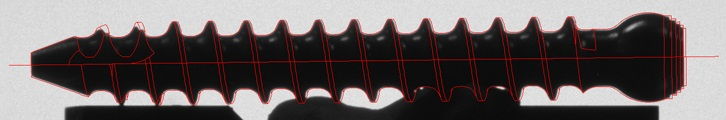

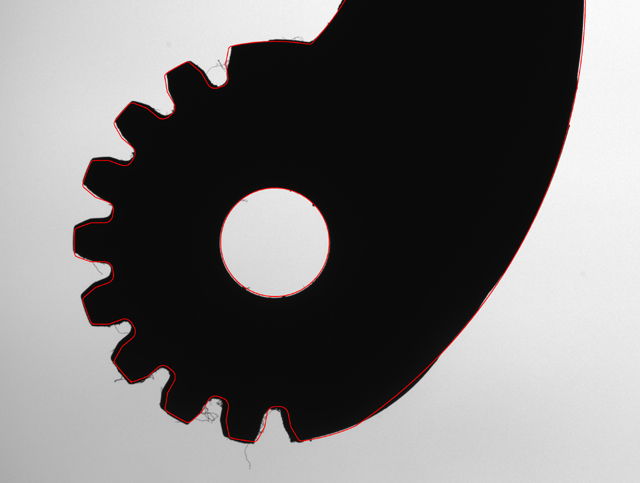

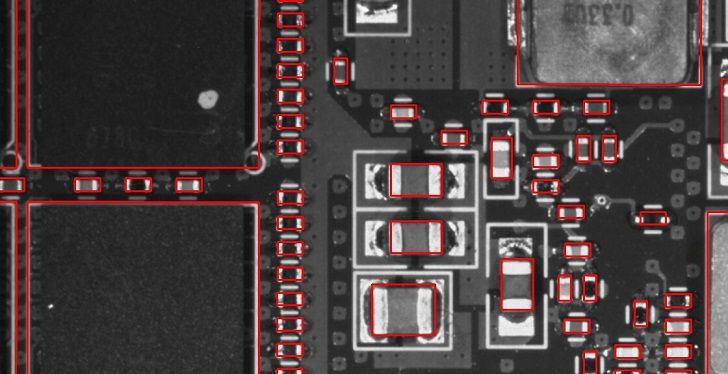

Our digital optical comparators are used by many companies across a wide range of industries. We provide solutions and customizations to ensure your application needs are being met. View some examples of applications we have solved within various industries below. If you don’t see an example of your unique application, please contact us to learn how we can support your needs.

A great many manufacturers across a wide range of industries are using VisionGauge® systems to generally improve and speedup their inspection & measurement process, reduce their costs, improve product quality and achieve much better Gage R&R performance.

VISIONx provides a wide variety of system types and configurations, each one suitable for any number of applications. Learn more about the differences between our horizontal and vertical digital optical comparators and when to use each type of system.

VisionGauge® Digital Optical Comparators / Profile Projectors are perfect for both the shop floor and the Quality Control lab. Contact us with your application’s requirements to learn about how our systems can benefit your inspection process. Our Application Engineers have a great deal of experience understanding the particularities of complex parts and using our tools to develop effective solutions for all types of inspections.

Sign-up for the VisionGauge® monthly newsletter for information on new features and new applications solved with VisionGauge® systems.

Are you interested in streamlining your inspection process with VisionGauge® Digital Optical Comparators and optical measuring systems? As your vision inspection system manufacturer, we’re available to provide support at any time, so browse our selection of products or contact us online today.

Learn More