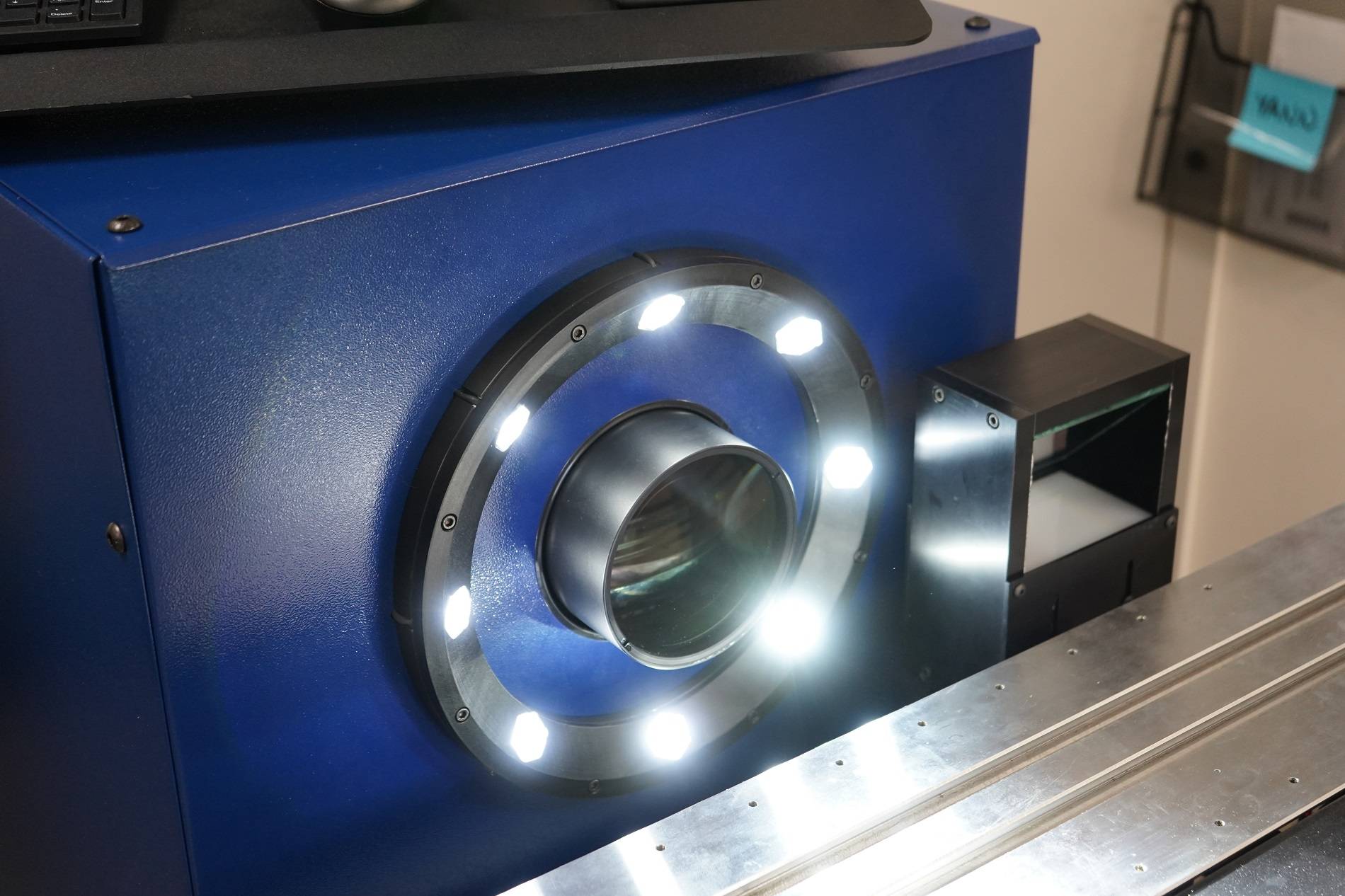

Octant-Based Reflected Illumination Module

New VisionGauge® Octant-Based Reflected Illumination Module To Solve The Most Demanding Applications

Illumination is one of the key components to successfully solve vision inspection applications. VisionGauge® systems already offer a variety of illumination modules, including: collimated and telecentric transmitted illumination, standard (off-axis) reflected illumination and on-axis coaxial reflected illumination modules.

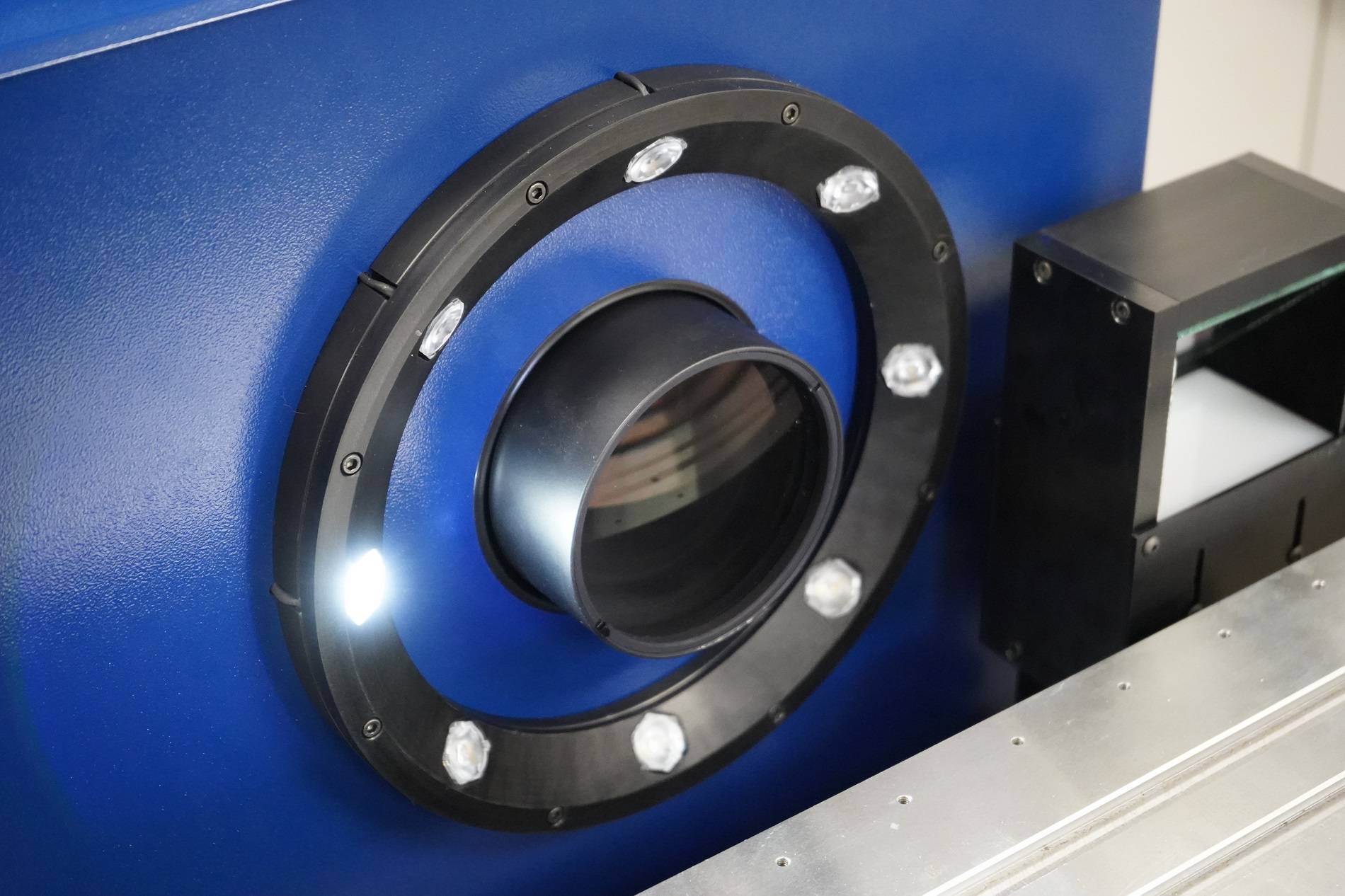

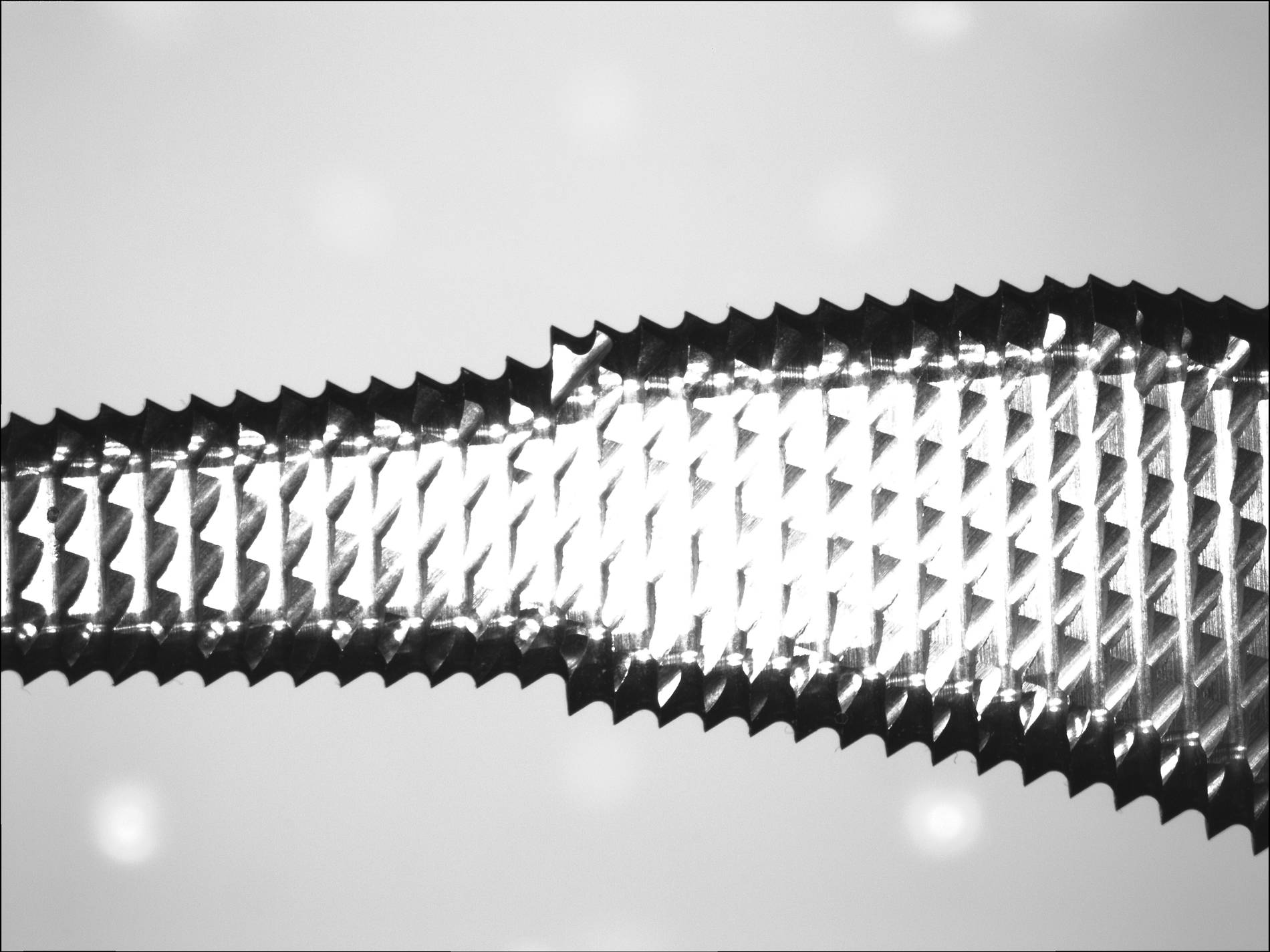

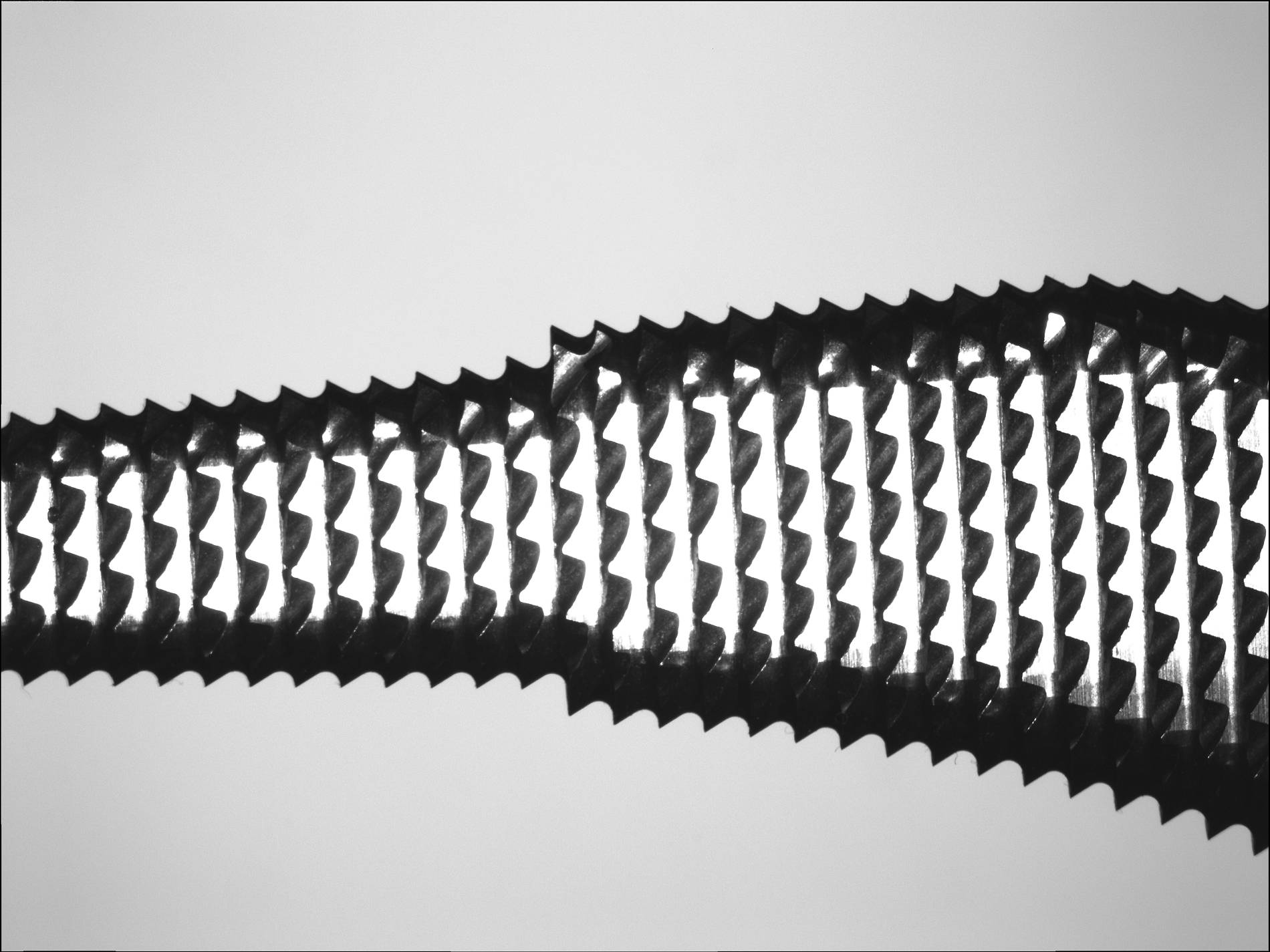

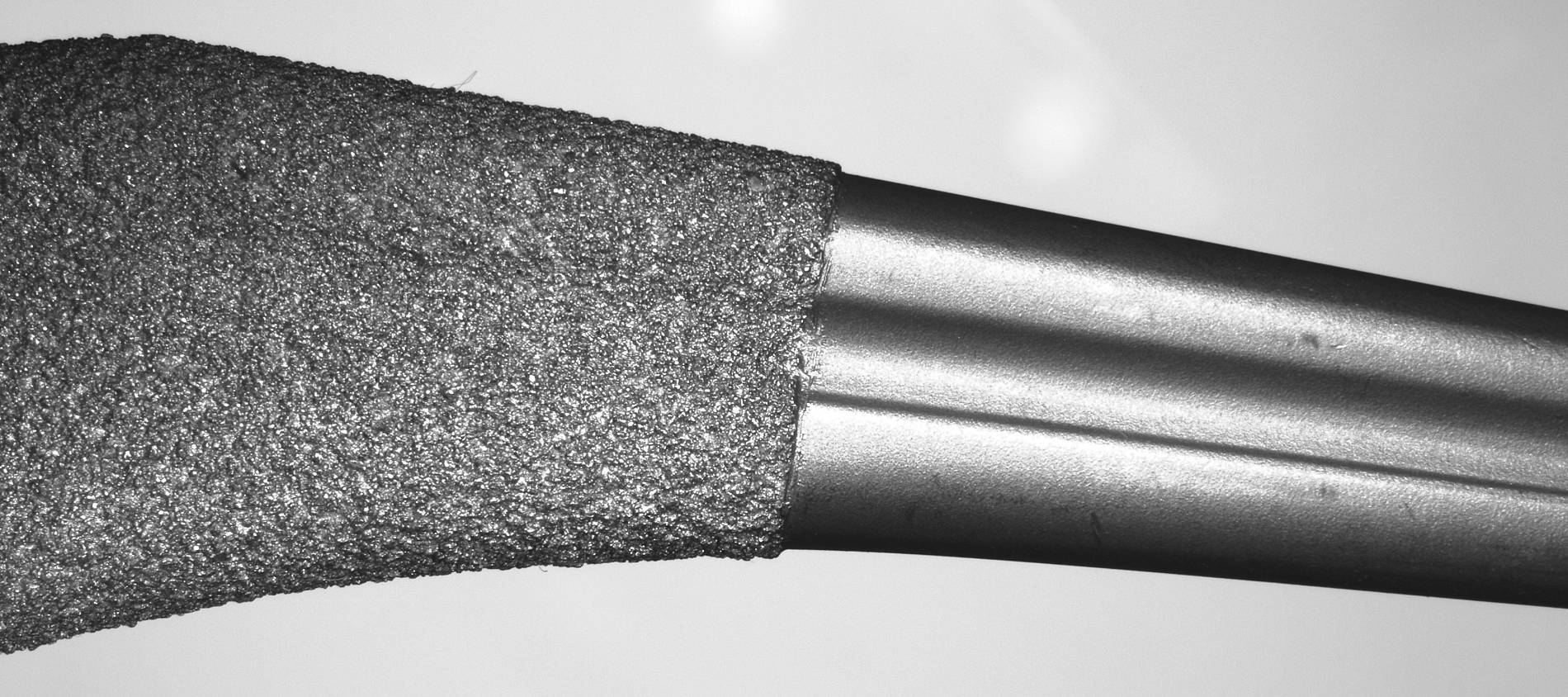

To complement all these different existing illumination modules, a new octant-based reflected illumination is now available as an option on all VisionGauge® systems. It projects off-axis reflected illumination from 8 different sectors and the distance between each of the light sources and the part plane is such that the resulting overall illumination is extremely uniform across the system’s entire field-of-view, with no “hot spot”. This is true for all system optical magnifications. This new octant-based illumination module is excellent for removing any shadows, even on parts with complex and unusual geometry.

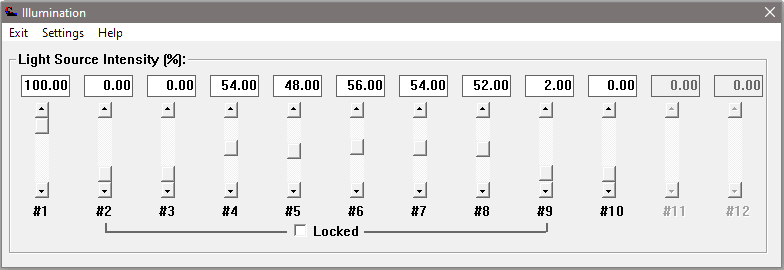

Lights can be controlled individually, by sector or all at once. There are no limits in this regard. In difficult applications, for example those involving parts with complex geometries, this type of directional illumination with fine octant-by-octant control can turn out to be the difference between a successful, robust solution and one that is unreliable and struggling.

VisionGauge’s® octant-based illumination is an extremely capable and flexible reflected illumination module that is especially well suited for fully automated applications that are typically the most demanding with regard to illumination flexibility, repeatability, and uniformity. VisionGauge’s® new octant-based illumination module further broadens VisionGauge’s® illumination toolbox and is suitable for all different types of materials, part geometries, and surface finishes.

Illumination Comparison

Like all VisionGauge® light sources, VisionGauge’s® octant-based illumination is LED-based and produces very low heat, requires very little power and remains stable over a very long lifetime. VisionGauge’s® stable and repeatable illumination produces very repeatable results.

With this new, advanced & flexible illumination the VisionGauge® systems are the ideal solution for the detailed inspection & high-accuracy measurement, directly on the shop floor and with no operator-to-operator variability, of a very wide range parts across many different industries.

Contact us to discuss how VisionGauge® systems can help you automate your inspection process, reduce costs, increase throughput and achieve higher accuracy.

Download a copy of this Application Note in .pdf format.