400 Series

The 400 Series VisionGauge® Digital Optical Comparators are innovative desktop inspection and measurement systems in a compact format.

The optical inspection system is designed with vertical and horizontal configurations and features manual stage movement across three axes for operator-driven reliability. Despite its compact size, this high-performing device offers high resolution, precision optics, and computer-controlled, ultra-bright LED illumination for sharp and clear images. It comes with a single high-resolution monitor that allows a full view of the entire image.

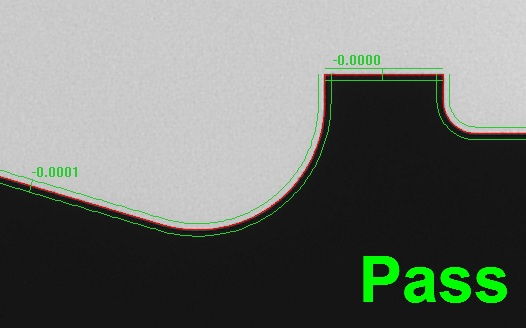

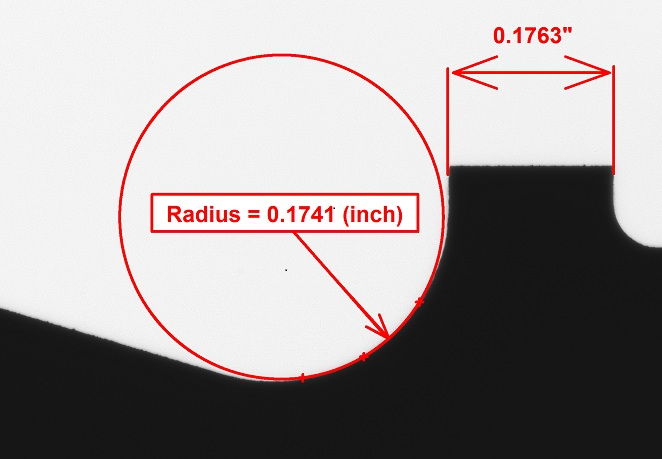

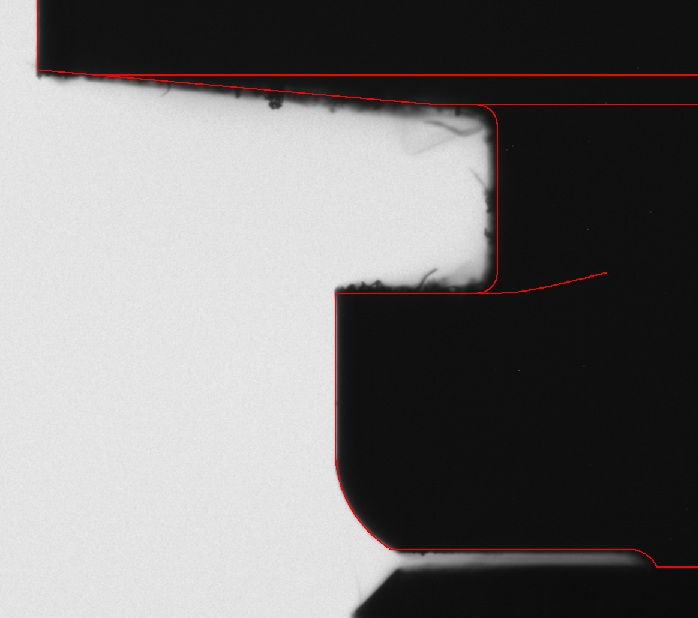

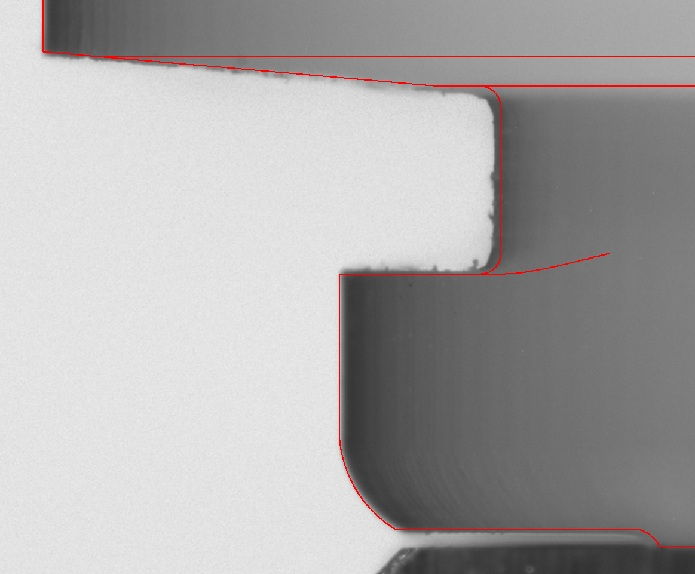

The 400 Series is a cost-effective inspection and measurement system with a complete set of features. It’s equipped with all the advanced and patented software capabilities VisionGauge® systems, including:

This desktop optical comparator is a versatile machine equipped with automatic data collection technology. It can obtain images, gather data, and generate reports without operator-to-operator variation. It’s a convenient tool offering advantages over traditional comparators. These advantages include:

Our optical inspection systems are continuously being improved with updates. The constant innovation enables us to cater to a wide range of industrial inspection applications with enhanced speed and accuracy. Our device’s features include: