Optical inspection sets the standard for part verification in major manufacturing industries in today’s high-tech world. We assist leaders in all types of businesses by offering custom automated optical comparators. With increased speed, agility and reliability, our optical comparators allow you to compare parts directly to their CAD data while accurately and efficiently completing inspections and digital optical measurements.

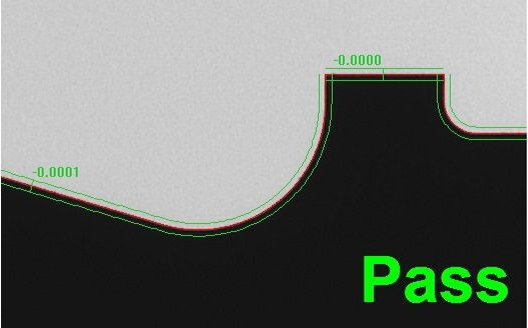

Our VisionGauge® Digital Optical Comparators streamline your manufacturing process by capturing images of manufactured parts and automatically comparing them to their CAD drawings. This ability means you can reliably confirm whether a component is within spec or catch production flaws before they go out the door. These optical comparators provide stunning accuracy, a necessary element in high-demand industries like medical manufacturing, aviation, aerospace, electronics and pharmaceuticals.

Learn about the various applications of our digital profile projectors and see if they’re right for your industry’s quality control.

VisionGauge® Digital Optical Comparators measure product consistency by comparing parts directly to their CAD file. This process is a quick, highly-accurate way to check for defects and verify all components conform to quality standards.

Digital profile projectors are precise and intuitive, delivering high-quality results in less time than traditional optical comparators. These machines are easy to use and because they can be fully automated, they operate swiftly and reliably. They also offer a convenient way to streamline inspections, enabling you to speed up operations, increase throughput, and eliminate operator error. Learn more about how digital optical comparators work!

VISIONx, Inc.’s digital profile projectors offer reports, charts, statistics and more. In addition to being fully digital, our inspection systems glean data straight from CAD drawings, saving time by making inspections simpler and easier to run. VISIONx’s update to traditional optical comparator machines will capture, qualify and report comparison data at the click of a button. Benefits of our digital optical comparators include:

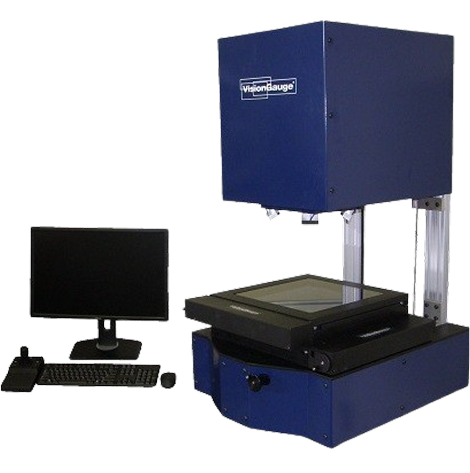

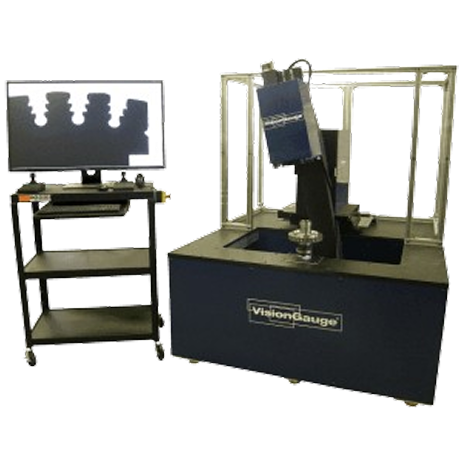

We have multiple digital profile projectors for sale. Our VisionGauge® Digital Optical Comparators use the latest technology and measuring tools to deliver high-quality images, capture reliable data and help you maintain quality control policies. We offer digital comparators in horizontal and vertical configurations to optimize your measuring processes:

If you upgrade an existing optical comparator to a VisionGauge® design, the component’s presentation to the camera will remain the same, meaning replacement is easy in the same horizontal or vertical configuration.

Our 300 Series Field-of-View Systems can help you increase productivity if you manufacture smaller parts for electronics, medical, or similar products. The design boasts an extended depth for objects as high as 4 inches and an extended working area, providing plenty of clearance between the lens and the part.

Several features include:

The 400 Series Desktop Inspection and Measurement System is a compact digital optical comparator machine with incredible accuracy and reliable digital optical measurements. With manual movement across three axes, the 400 Series is ideal for lower-volume applications that require precision measurements.

Features of the 400 Series include:

The 500 Series Digital Optical Comparator earns its name by setting the standard for optical quality control equipment everywhere. This machine is the most powerful digital optical comparator on the market and can handle almost any demand thanks to its high efficiency, user-friendly design and precision optics.

Features include:

The Super-Extended-Travel configuration of the 500 Series VisionGauge® Digital Optical Comparator delivers reliable, high-accuracy performance for measuring large and heavy parts. The innovative design provides optimal rigidity and minimizes mechanical deflection for various components, including parts in the power generation and gas turbine industries.

Examples of the primary features include:

The Compact 500 Series VisionGauge® Digital Optical Comparator is designed for high-accuracy inspection & measurement of small parts for space-limited applications, and it includes all of the functionality of the standard 500 Series systems.

Features include:

The 600 Series VisionGauge® Inspection and Measurement Systems are designed to check turned and rotationally symmetrical parts in a compact desktop format. The system is very flexible and available with a wide range of customizable workholding setups for crisp surface feature inspection across a wide range of industries.

Features of the 600 Series comparator include:

Our 700 Series 5-Axis Inspection and Measurement System offers the ultimate solution for work with more intricate electronic or mechanical parts. This measurement system is optimal for complex aviation, aerospace, and power applications.

Features of the 700 Series comparator include:

If you are looking for an inspection system ready to integrate into your existing process that can take on your most complicated automation applications, you may benefit from the VisionGauge® Standalone Inspection & Measurement System. The Standalone’s design leverages precision optics and advanced software to provide greater efficiency, accuracy, and speed compared to older models.

Product features include:

The VisionGauge® Disk Inspection and Measurement System is the ideal solution for companies that manufacture and inspect turbine disks. Our resources will allow you to detect flaws and confidently turn out higher-quality turbine disks.

Examples of features include:

Our VisionGauge® Digital Optical Comparators allow you to speed up your measurement and verification operations, helping you establish a more effective, accurate inspection process for your business. If you’re looking for a system that meets specific job requirements, we also have the inspection technology to offer customized solutions and multiple configuration options.

Please browse our measurement tools and systems to find the perfect solution for your unique application. If you want to learn more about how partnering with the industry’s leading digital optical comparator manufacturer can benefit your business, our experts can guide you. Contact us online today for additional information or to find a purchasing location to buy optical comparators near you.

CONTACT US