Designed specifically for automation applications.

Designed specifically for automation applications.

The system is widely-applicable and extremely general purpose, and it can be easily dropped into an existing automated cell.

Our VisionGauge® OnLine software includes Remote Program Communications, an extensive set of communication protocols over a variety of interfaces (via TCP/IP over ethernet, digital I/O’s, COM port, etc.) for full 2-way handshaking (with a robot or cell controller, for example), error/result reporting, and remote control over automated program operations.

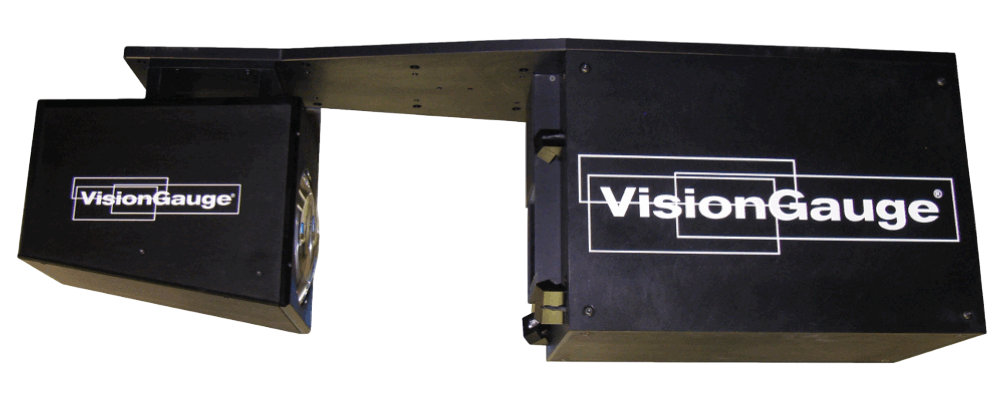

The VisionGauge® Standalone Inspection & Measurement System includes all of VisionGauge®’s advanced inspection and measurement tools, including our patented CAD Auto-Align, CAD Auto Pass/Fail, and the patent-pending Tooth Checker tool, making it perfect for automatically carrying out very high-accuracy inspections and measurements.

In addition to its versatility, the VisionGauge® Standalone Inspection and Measurement System has many benefits compared to existing technology. Our adaptable software intelligence in automation means there is less reliance on operators and more focus on software and tools. This model combines advanced software and precision optics to offer greater speed, accuracy, and efficiency compared to older measurement devices.

Additional advantages of using our video inspection measurement systems and equipment include:

The benefits of using a VisionGauge® system are evident in its state-of-the-art inspection and measurement features – particularly its intuitive image analysis technology and sub-pixel accuracy. Our video measuring equipment has features that make it one of the best quality control solutions for a wide variety of industries. Medical device manufacturing, military & defense, aerospace, automobile manufacturers, and many more can use this system to improve daily operations.

The VisionGauge® Standalone Inspection and Measurement System’s features include:

Technical Specifications may be found in the downloadable data sheet.

A computerized video measuring system inspects live images of manufactured parts, often using a computer-aided design (CAD) file as a reference. Older systems may have required extra physical components like templates and overlays. Using digitized CAD data directly eliminates the need for those resources. When comparing a part to its design specifications, performing measurements, performing defect detection, etc., the system collects data and may generate a Pass/Fail result. Manufacturers use that information to conduct quality control processes.

Controlling the quality of the parts you produce is crucial. Modern measurement devices are faster, more powerful, and more accurate than traditional models. The efficiency and reduction of operator errors associated with using modern video inspection equipment outweigh the cost of a video measuring system.

The VisionGauge® Standalone Inspection and Measurement System is a versatile solution for your automation and inspection needs. Precise and convenient, the standalone model serves as a drop-in device for robot-controlled, automated cells. Combined with ease of installation, this system can solve a vast array of of applications and works well for general purpose inspections.