VisionGauge® OnLine version 14.28, dated September 14th, 2020, is available for download.

The following enhancements have been added over the last few versions:

VisionGauge® OnLine now allows is capable of writing a “Usage Tracking” log. This option is found in the “Settings – General Preferences” menu. When enabled, a log file is created in the “vgOnLine/Log” directory with information about when a session of VisionGauge® OnLine is started and shut down. The date, time, and Windows user that started the session are recorded on each line.

![]()

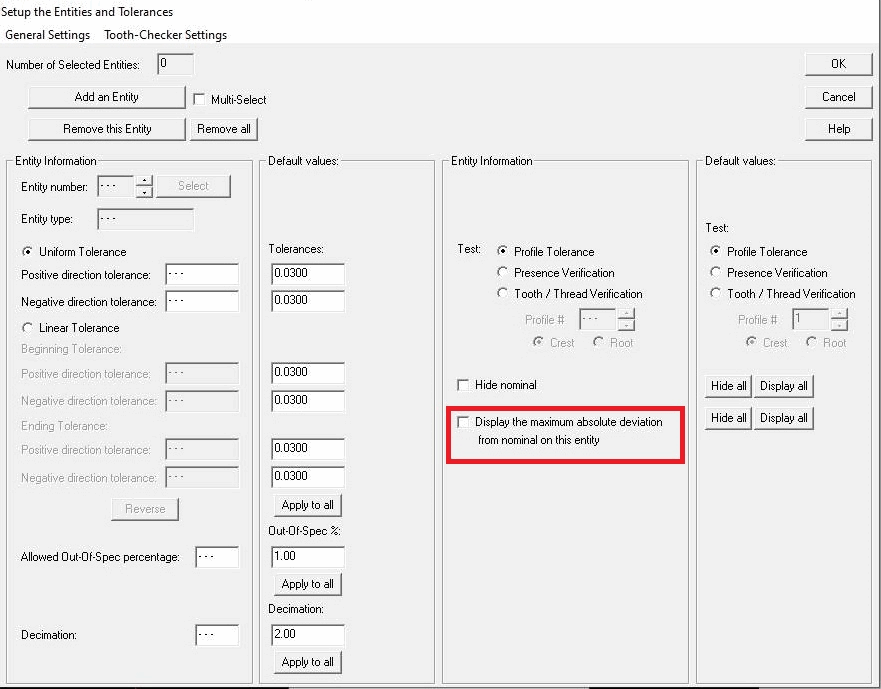

This update also includes a redesign of the CAD Auto-Pass/Fail “Entities” window. We’ve also added the ability to display the maximum (absolute) deviation from nominal on user-specified entities during CAD Auto-Pass/Fail® operations.

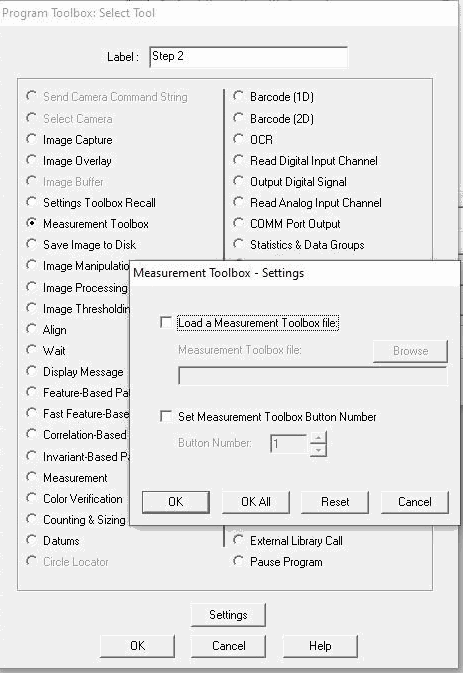

The Program Toolbox now includes a “Measurement Toolbox” option, allowing a program to automatically select an .mtb file to load and which button to select by default. This tool could be useful when a program needs to be paused to instruct operators to perform manual measurements before resuming the program again.

Also, the DXF Correspondence File now includes an additional optional parameter for which Measurement Toolbox file to load. This allows operators to automatically load VisionGauge® OnLine programs, auxiliary files, overlays, and/or a specific Measurement Toolbox by using the barcode reader. The DXF Correspondence File information has been updated with this data.

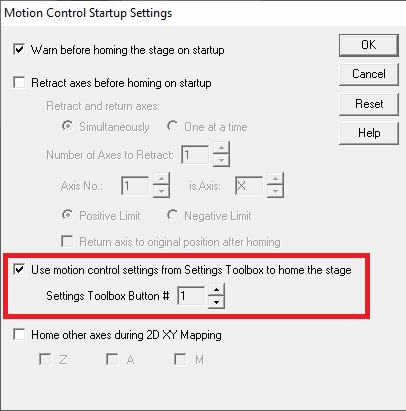

The Motion Control Startup Settings now contain an option to customize the startup warning message when the 2D XY Stage Mapping is about to begin its homing procedure. This notification window is much larger so it is more visible, and it allows multiple lines of customized text with Unicode support to give operators specific instructions for when the system starts.

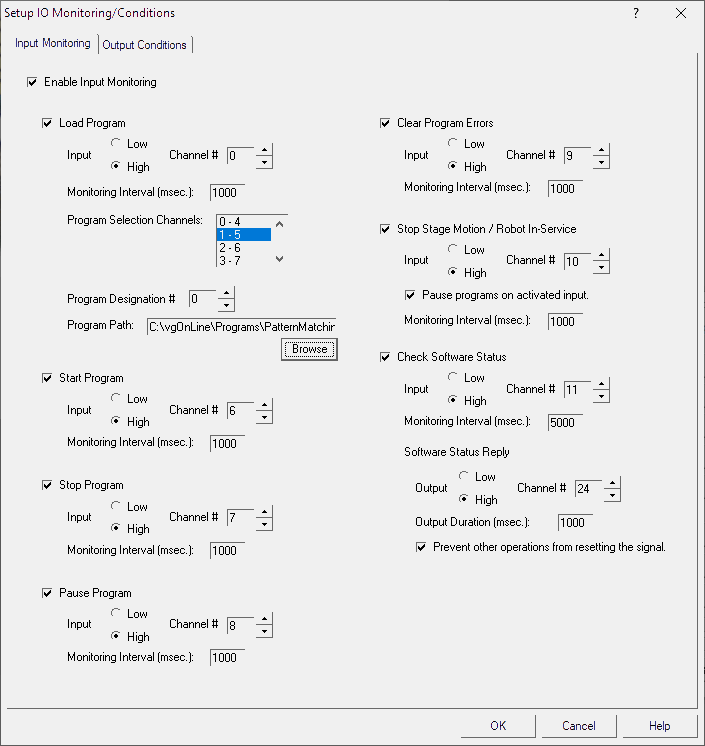

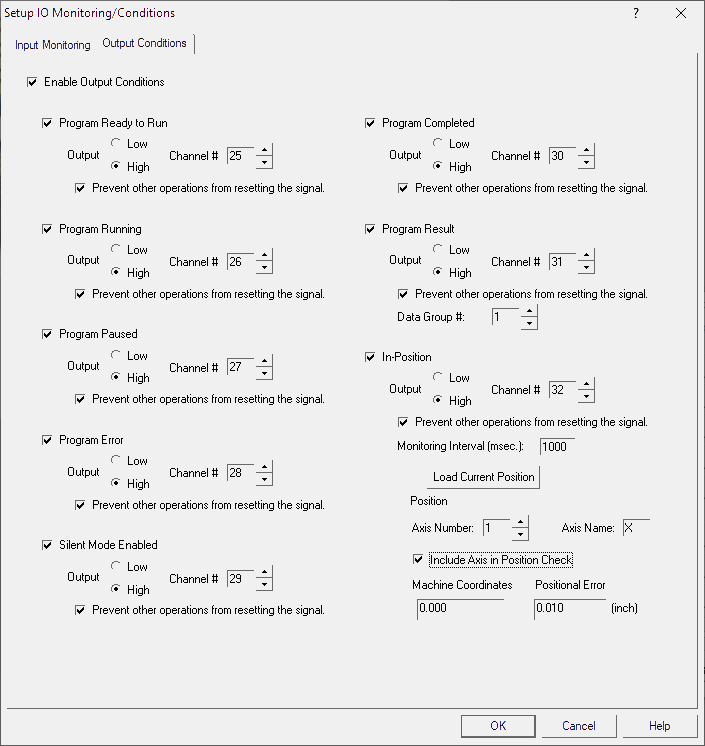

This set of updates also adds a Digital IO output condition for when a system’s Emergency Stop is triggered during program operation.

The Settings Toolbox now includes an option to save the current measurement units. This allows a Settings Toolbox button to reset the measurement units when it is recalled, which could be useful if different sets of measurements require different units.

Finally, this update also includes a few performance enhancements, measurement improvements (Manual and Automated Perpendicularity measurements), small fixes that correct the display of camera names when multiple cameras are selected, and add additional support for Unicode in various input locations of the software.