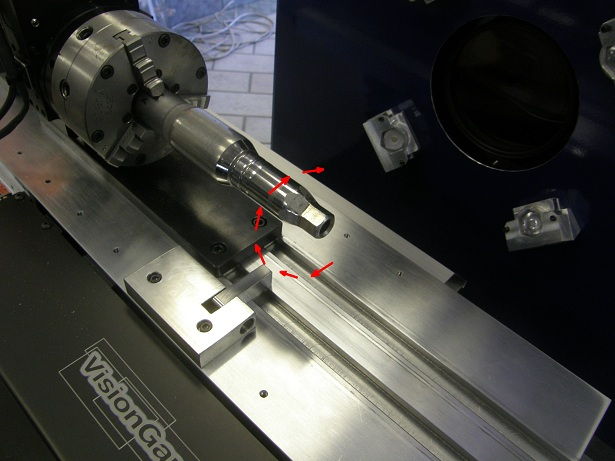

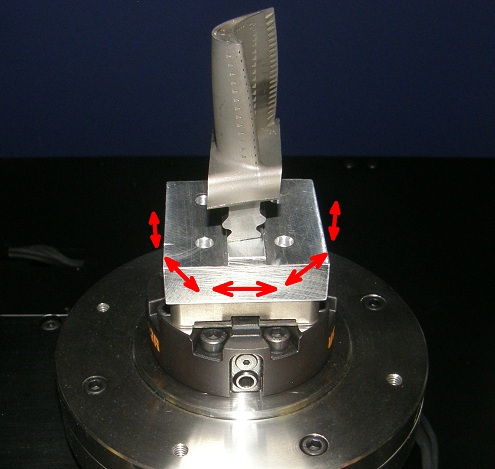

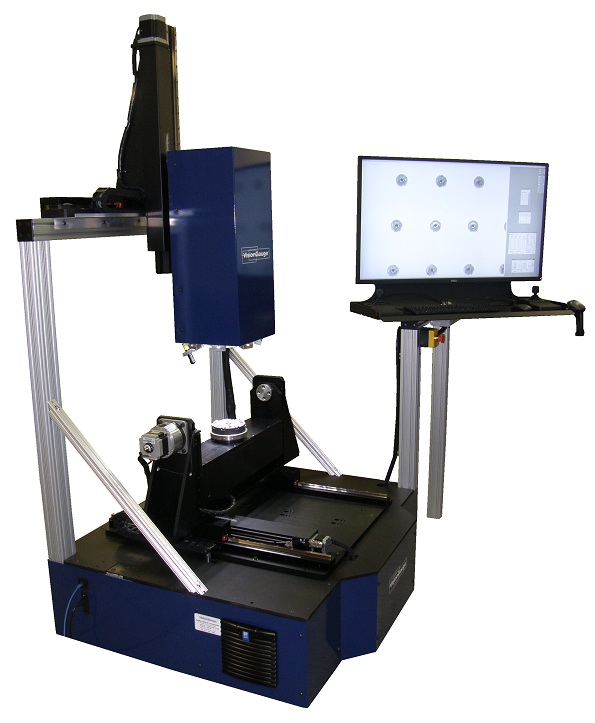

VisionGauge® features an automation module with extensive communication capabilities for full 2-way handshaking with a robot, cell controller, or part-positioning equipment, for example. Connect to external devices by TCP/IP over Ethernet or wireless, digital I/Os, RS232, etc… to automate program control, loading programs, reporting, trigger/signal management, and much more.

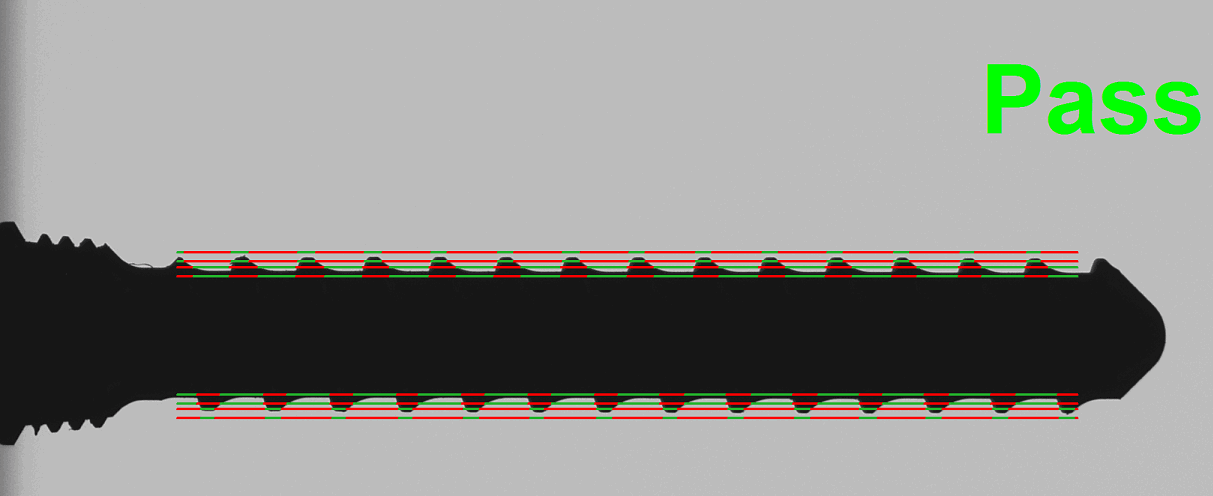

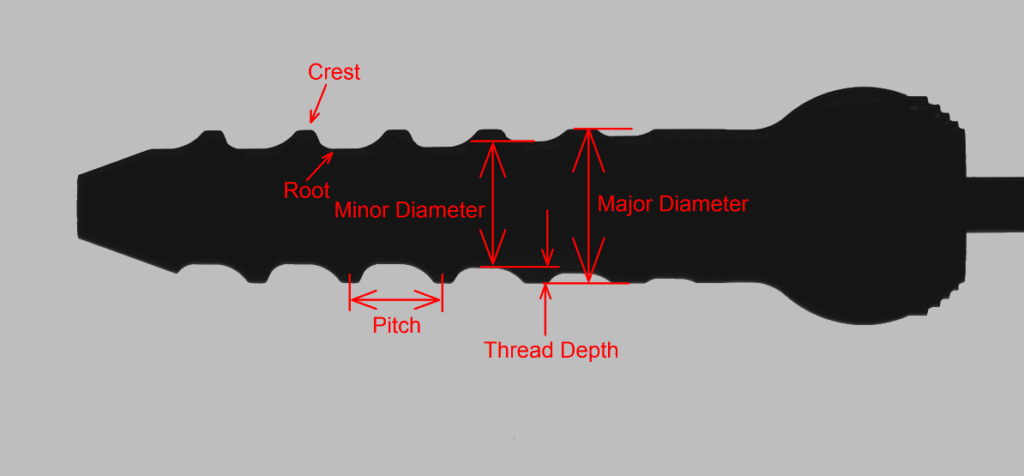

VisionGauge® systems can easily be dropped into an existing automated cell to provide advanced inspection and measurement capabilities, including those provided by our patented CAD Auto-Align™, CAD Auto-Pass/Fail™ and Tooth Checker™ tools.

Learn more about VisionGauge®’s complete inspection automation capabilities.

Contact us with the details of your application!