Read our new press release “The New Compact 500 Series VisionGauge® Digital Optical Comparator – Complete Inspection & Measurement in a Small Footprint“.

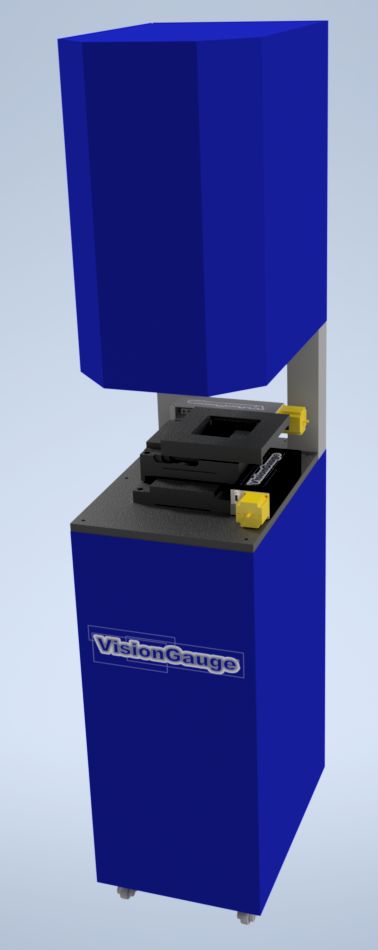

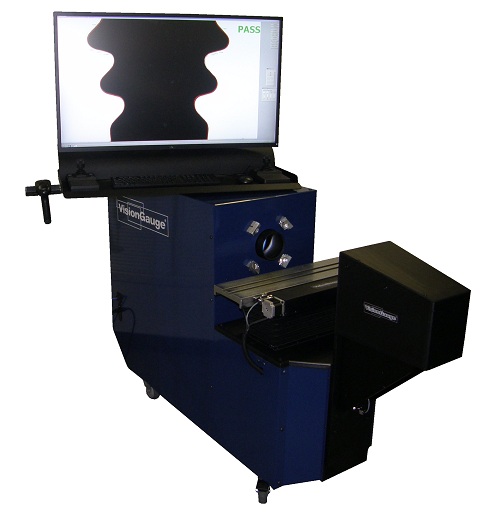

The new Compact configuration of the 500 Series VisionGauge® Digital Optical Comparator was developed for applications requiring full inspection functionality but where floorspace is very restricted.

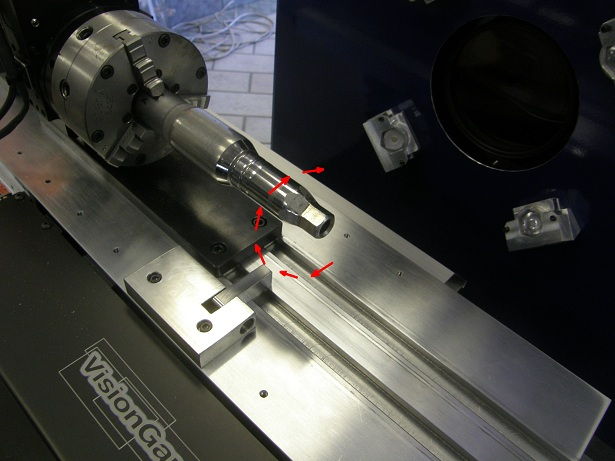

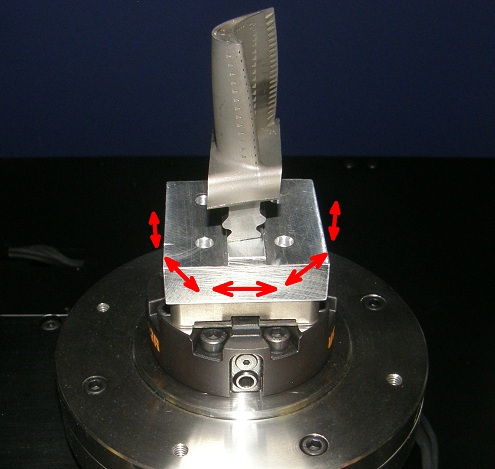

This floor-standing system has a motorized XY stage with 4” x 4” travel and 0.25-micron encoders as well as a motorized Z axis with autofocus.

Along with its very compact footprint, some of the system’s big advantages include the availability of VisionGauge®’s:

- i) very high-resolution multi-magnification optics

- ii) wide range of illumination options, to tackle even the most challenging applications and

- iii) LASER module for Z-axis / depth & height measurements.

Learn more about the new Compact 500 Series VisionGauge® Digital Optical Comparator.