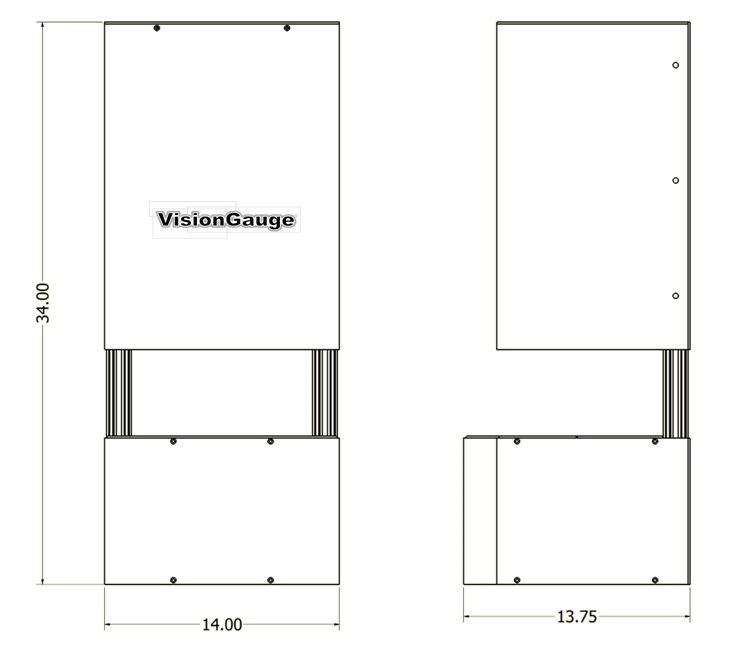

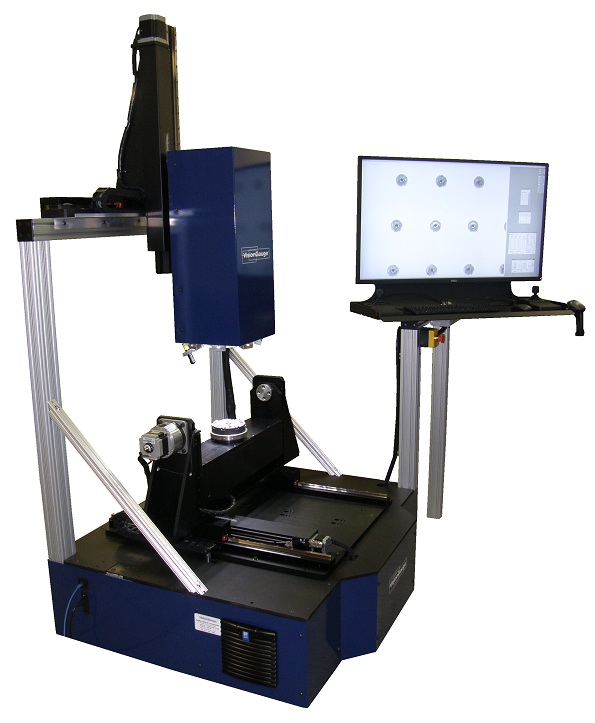

Many other options are available with the VisionGauge® Digital Optical Comparator, including:

- Adapted NIST-traceable stage micrometer with certificate of calibration (this will allow you to carry out the yearly re-calibration yourselves)

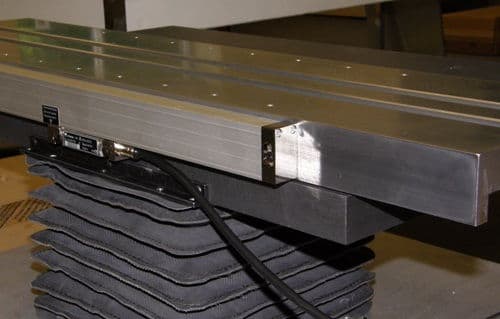

- Upgrade of the X and Y axis encoders from 0.5 um resolution to 0.1 um resolution.

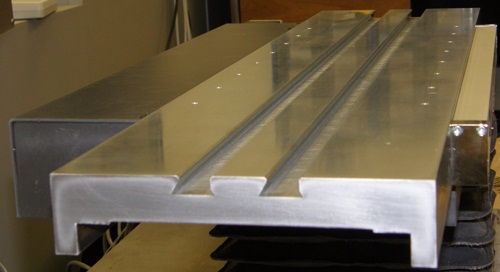

- Extended (i.e. 24″) X-axis travel stage upgrade (from the standard 12″ travel) for Horizontal configuration VisionGauge® Digital Optical Comparator

- Extended (i.e. 12″) Y-axis travel column upgrade (from the standard 6″ travel) for Horizontal configuration VisionGauge® Digital Optical Comparator

- Extended (i.e. 24″ x 24″) X-axis and Y-axis travel stage upgrade (from the standard 12″ x 12″ travel) for the Vertical configuration VisionGauge® Digital Optical Comparator

- Extended (i.e. 12″) Z-axis travel. Applicable for either the horizontal or vertical configuration of the VisionGauge® Digital Optical Comparator

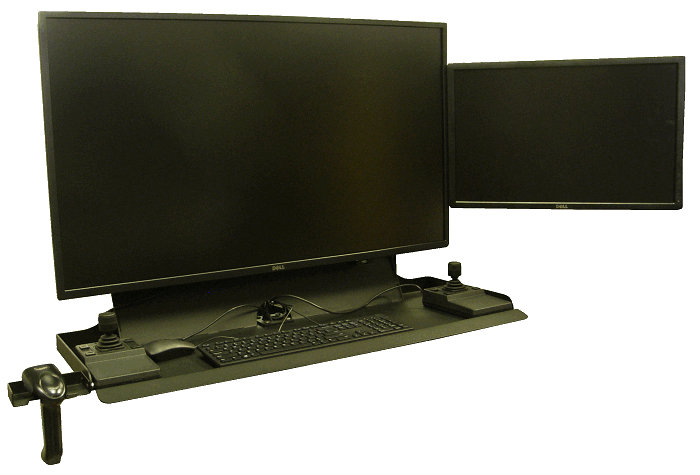

- “Additional monitor option” to automatically load and display inspection instructions & criteria or other related documents when the work order barcode is scanned to automatically load the appropriate CAD file

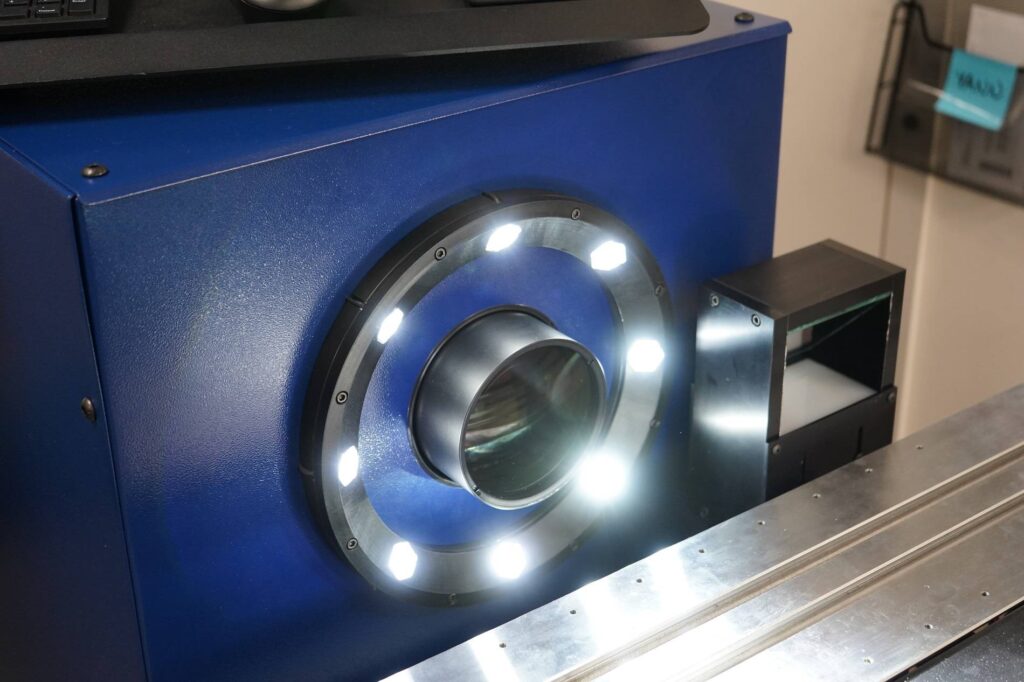

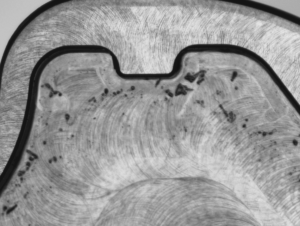

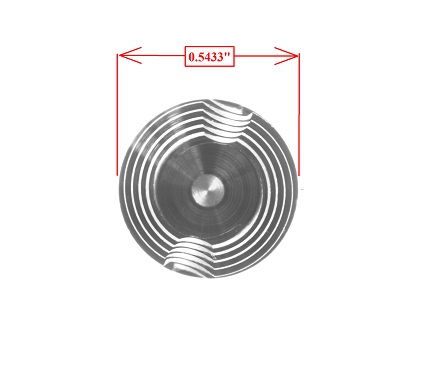

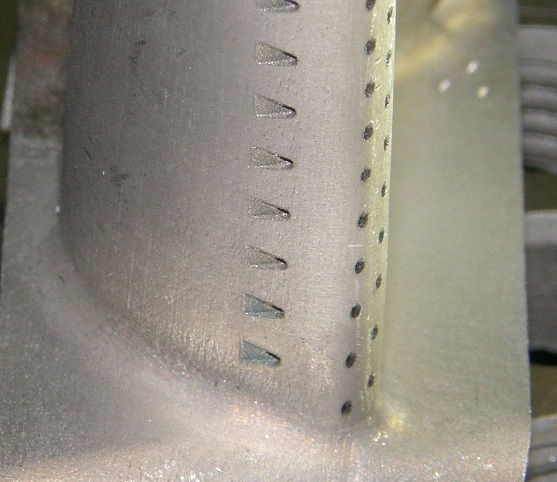

- On-axis reflected LED illumination module (programmable and computer-controlled) fully integrated with VisionGauge® Digital Optical Comparator. This reflected (i.e. “front”) illumination module produces a very different type of front illumination that is very “flat” (i.e. “shadow free” and low glare) that is more appropriate for certain types of parts. This illumination module is mounted on a “swing arm” to allow the operator to easily put it in position & retract it when it is not needed.

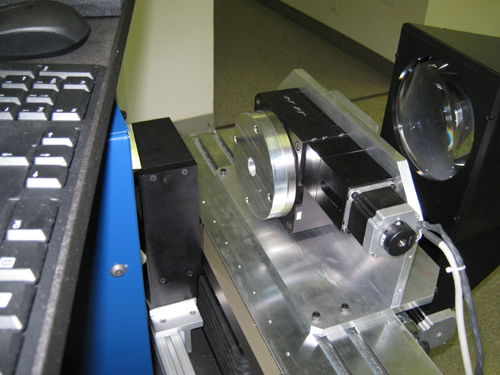

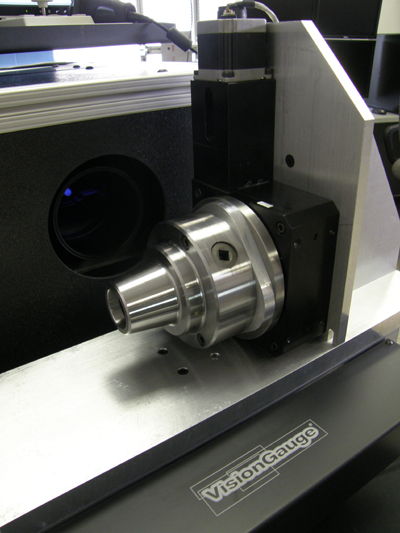

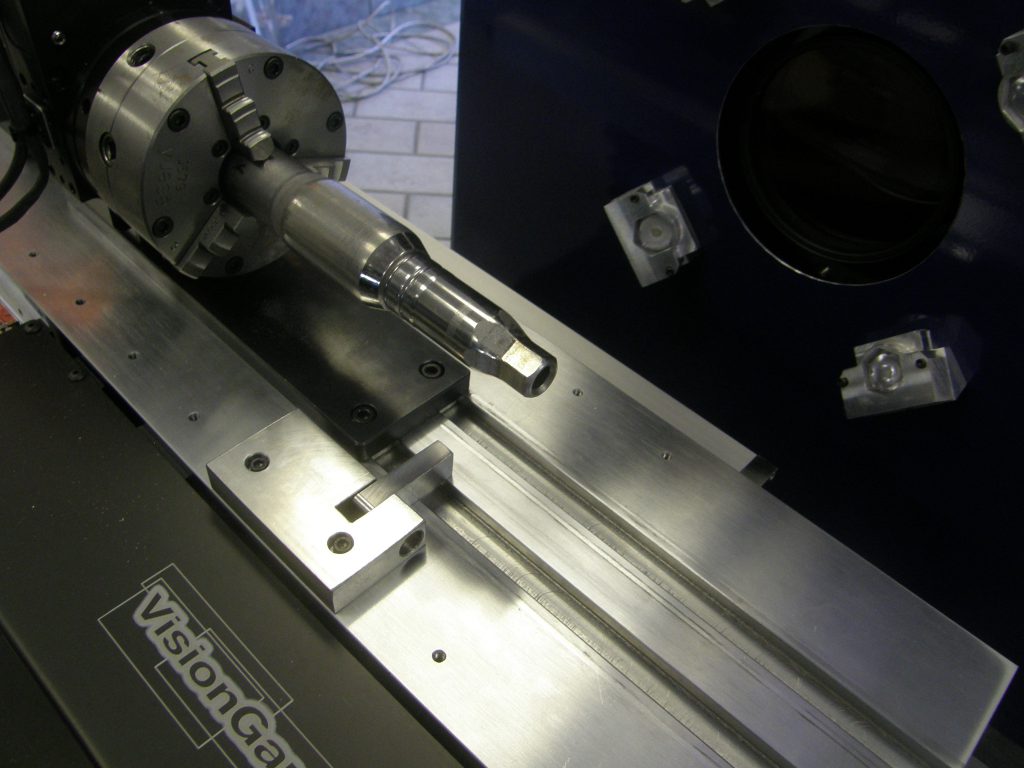

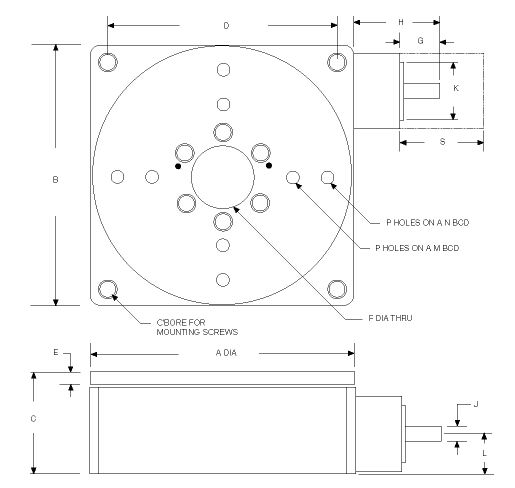

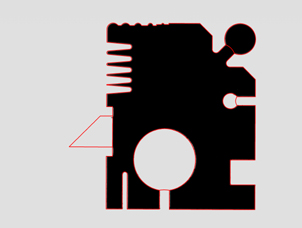

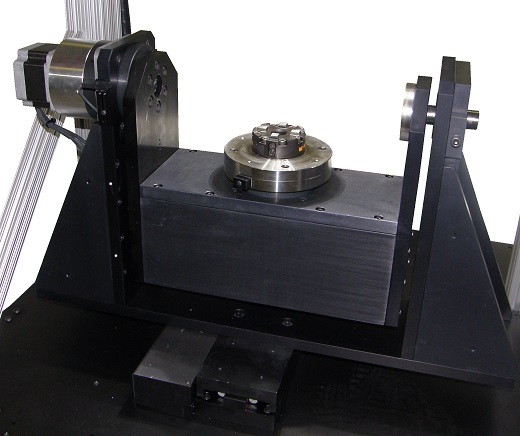

- Supplementary rotary encoded motorized axes (i.e. to rotate the part), including:

- All required motion control hardware for the supplementary motorized axis (for part rotation). This motion control hardware is completely and seamlessly integrated with the system’s existing motion control hardware

- Motorized encoded high-accuracy rotary stage

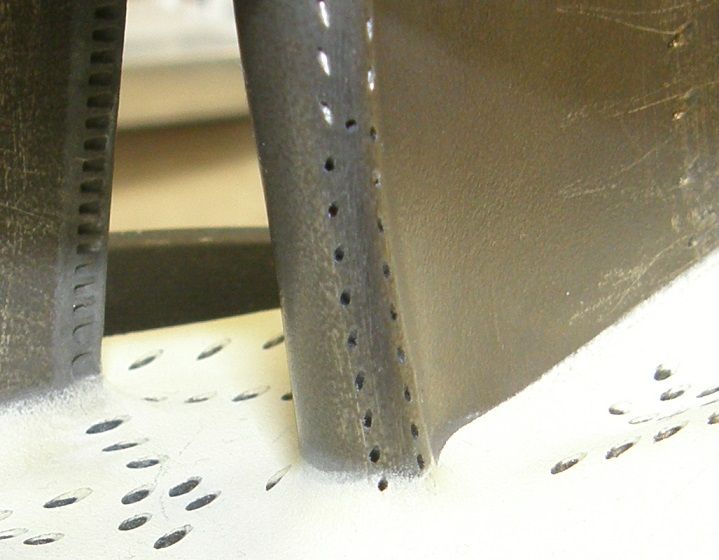

- Fixture to mount the stage to the system’s dovetail grooves

- All required cables & power supplies

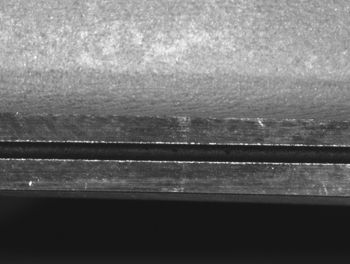

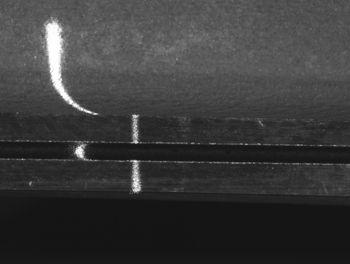

- LASER module for Z-axis measurements, including:

- High-accuracy structured LASER module

- LASER controller hardware (to completely control the LASER’s operation from within the software)

- Adapted fixture to mount the LASER module onto the Z axis stage

- Software upgrade

- All required cables & power supplies

- Optional standalone “desktop” software license (to allow you to remotely view your CAD files, setup tolerances, create automated inspection and measurement programs, etc…)

- VisionGauge® Annual Support and Update Program Membership Renewal (which provides users with unlimited technical support and free software updates for a full 1-year period). Note that unlimited technical support and free software updates are included for the 1st year with every VisionGauge® Digital Optical Comparator (Patent Pending) system.

- Replacement air filter (this is the only “consumable” part in the entire system!)

Other accessories, system configurations, fixturing (etc…) are also available…

Please contact us for more information including a detailed spec sheet, a “Frequently Asked Questions” document, pricing, etc…