A wide variety of plastic materials are used in medical implants. For example, today most total knee replacement implants and many total hip replacement implants contain ultra-high molecular-weight polyethylene (UHMWPE). Among other benefits, this plastic provides cushioning and movement. Other examples of plastic medical implants include high density polyethylene (HDPE) for facial reconstruction implants and polyketones (PEEK) that are common for spinal applications. For the right applications, plastic materials can present significant benefits as plastics are in general both more resistant to chemicals and lighter than metals. Given all of this, it’s not surprising that the range of medical implant applications for plastics is very wide.

Many plastic medical implants can be produced using conventional manufacturing processes such as CNC machining, injection molding, and 3D printing. This allows the fabrication of medical implants with very complex and unique geometries.

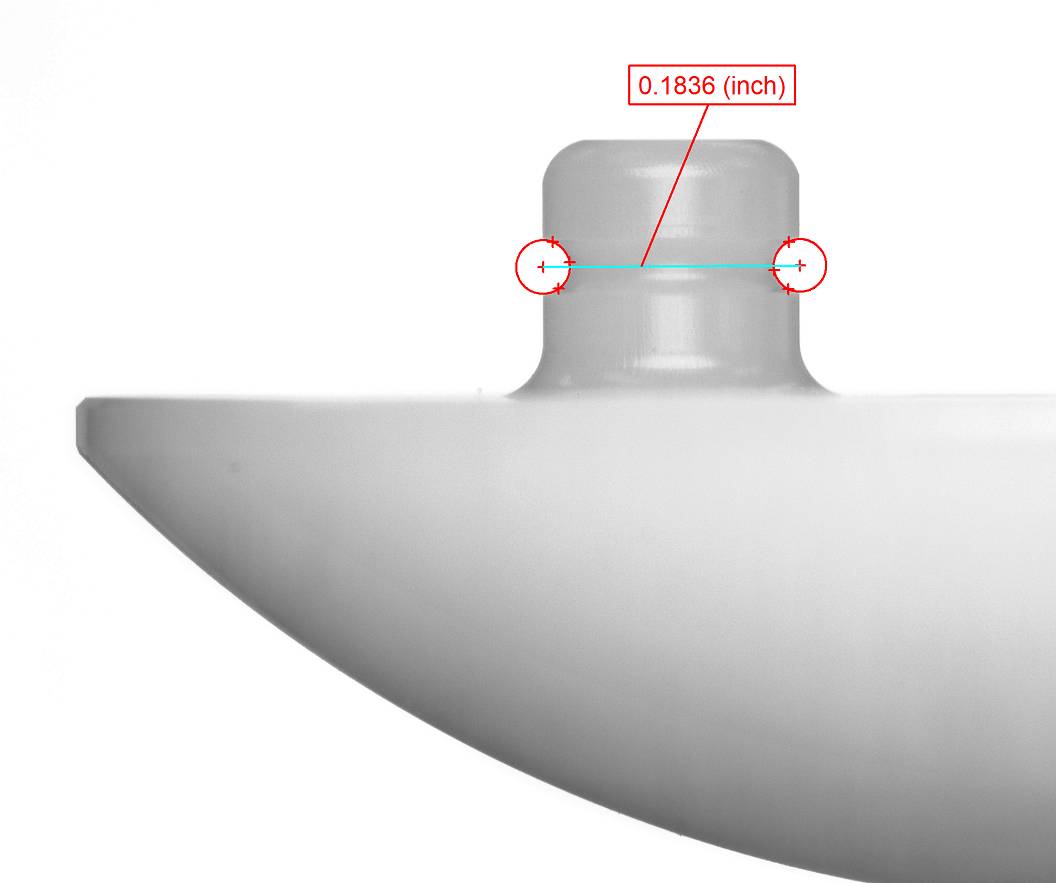

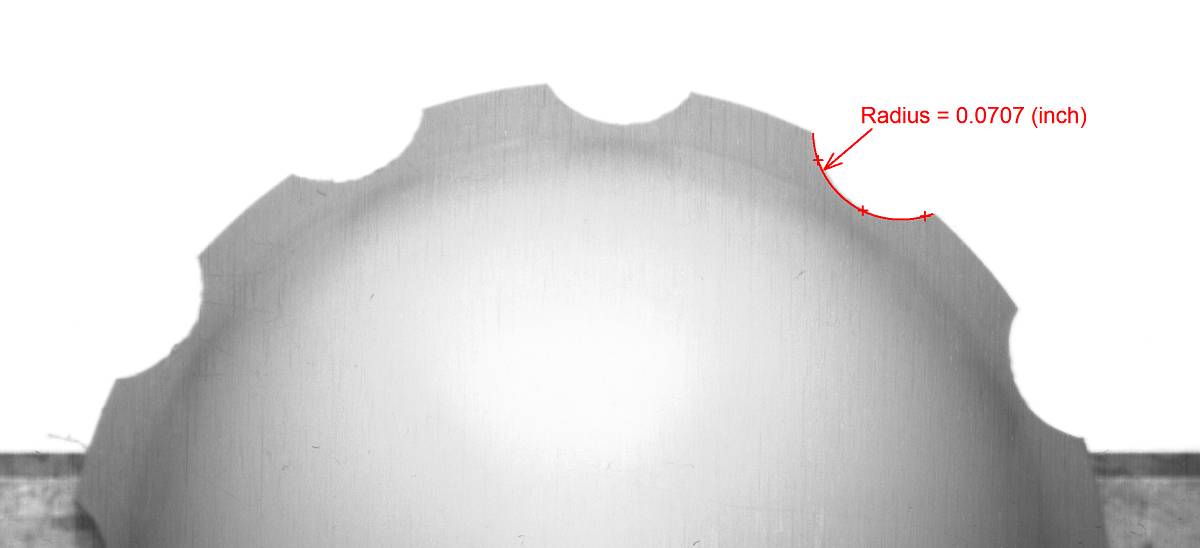

However, like with all medical implants, the tight geometries involved need to be precisely controlled. In the past, this was often problematic as traditional optical comparators, historically one of the most used inspection systems for medical implants, have struggled when dealing with plastic parts. Specifically, the image of plastic parts produced by these systems tends to exhibit lots of glare and reflections. With traditional optical comparators, it’s often difficult to determine an appropriate level of illumination for plastic and polymer implants that allows the user to make out the features of interest without creating an over-brilliance of other surfaces. It’s a difficult balance that tends to introduce even more operator-subjectivity.

The VisionGauge® Digital Optical Comparator overcomes all these limitations. Its illumination is based on new and completely different technology that produces crisp and clear high-resolution images, with high contrast and superb definition, of plastic parts. Furthermore, all of VisionGauge®’s illumination is LED-based and programmable. This eliminates operator-to-operator variability and produces repeatable illumination conditions for extremely repeatable plastic parts measurements!

VisionGauge®’s illumination is extremely flexible and many different types are available (i.e. transmitted, reflected on-axis and off-axis, etc.). The LED-based illumination also produces very low heat, requires very little power and remains stable over a very long lifetime.

With its new, advanced and flexible illumination, the VisionGauge® Digital Optical Comparator is the ideal solution for detailed inspection and high-accuracy measurement of the wide variety of plastic medical implants being produced by today’s medical manufacturers – directly on the shop floor with no operator-to-operator variability.

Contact us about the details of your application and learn more about the other applications VisionGauge® Digital Optical Comparators can solve.wy

Learn More