Application note,

Applications,

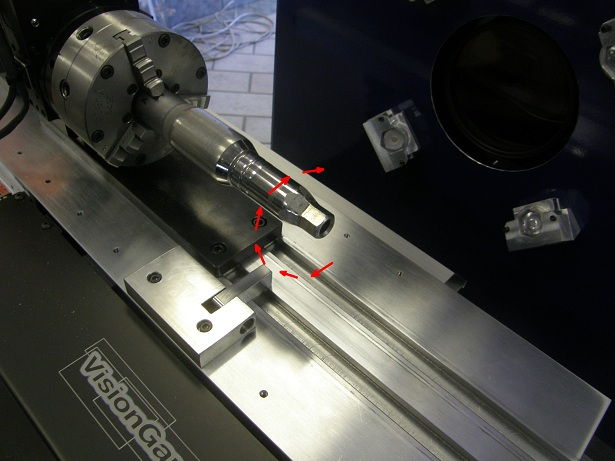

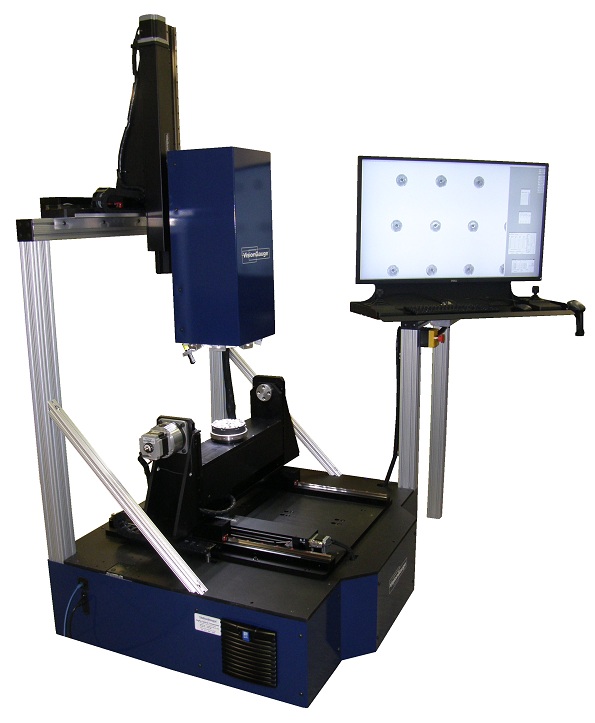

Digital Optical Comparators,

News/New Developments,

Software Feature,

VisionGauge® Online

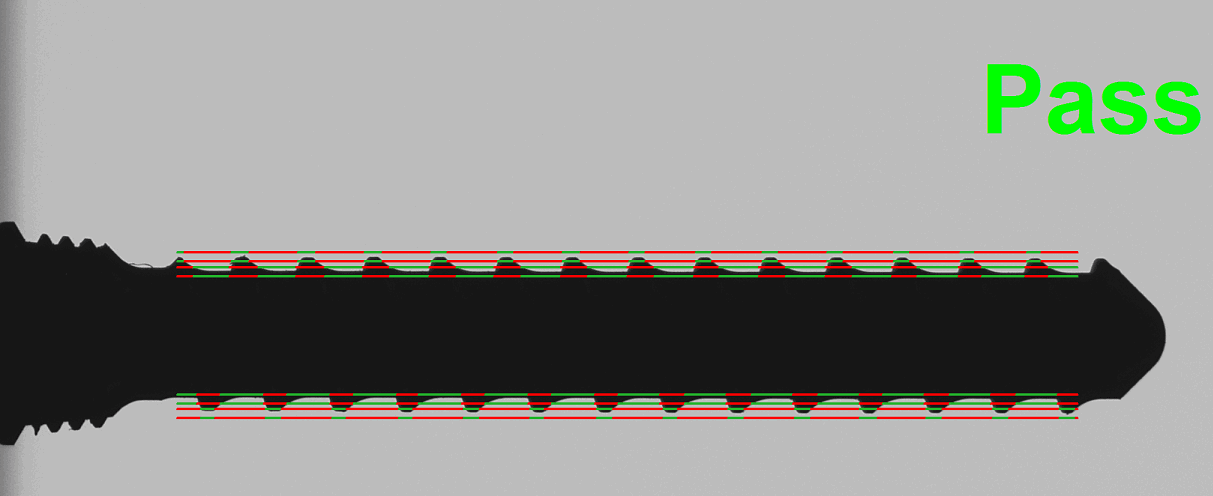

Introducing VisionGauge®’s Patented “Tooth Checker™” tool

VisionGauge's Patented Tooth Checker Tool Is The Perfect Device For All Part Inspection & Measurement Needs. Contact Our Team Today …January 8, 2020

1 MIN READ