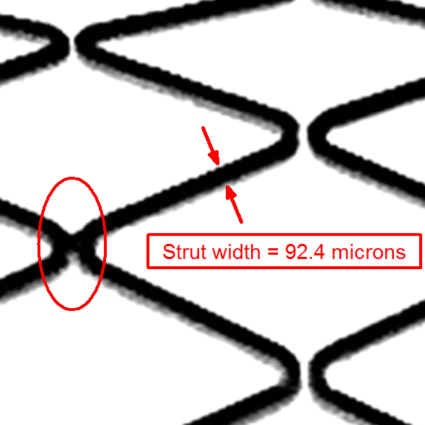

VisionGauge® Digital Optical Comparators have a broad set of measurement, defect detection, and pattern-matching tools to quickly, easily, and accurately carry out all required verifications. Our solutions range from manual to fully automated, so you can choose the right one for your operation.

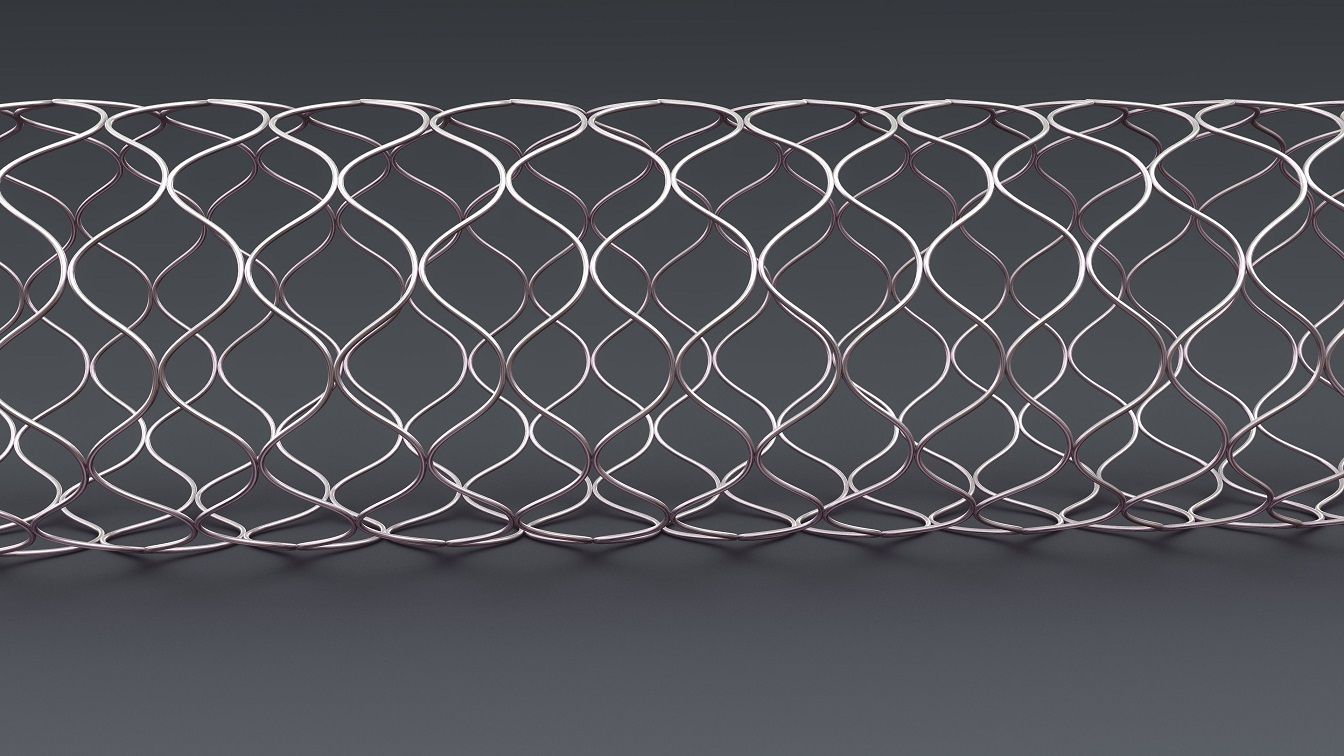

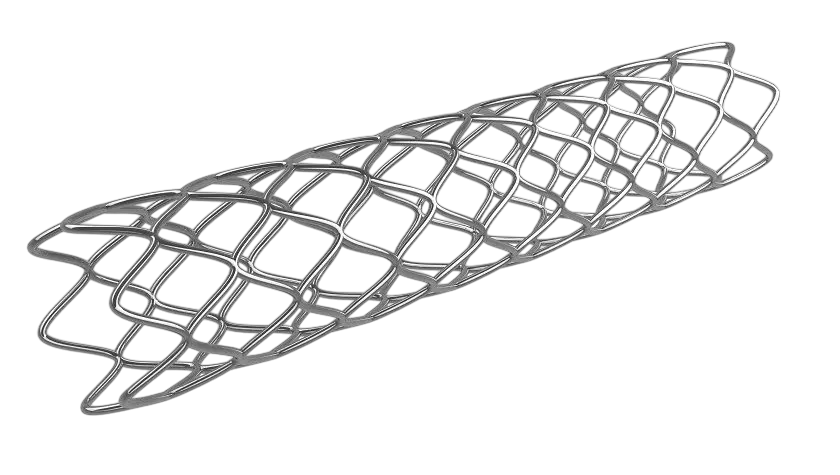

With no limitations on stent length or diameter, you can verify parts across the entire stage travel and check even large parts at high magnification with very fine resolution. The system supports both bare-metal uncoated stents and drug-eluting coated stents.