Orthopedic reconstructive and reparative procedures commonly use medical bone screws as fixation devices. Among other applications, they are employed for bone-to-bone fixation. The bone heals better and faster if the fractures are pressed together firmly by orthopedic screws. The advantage of these screws is that they reduce the gap between the bones, and, consequently, decrease the stress. Another common use of medical bone screws is to attach various implants, such as plates, to the bone. Medical bone screws are also utilized for a variety of other general anchorage and fixation purposes.

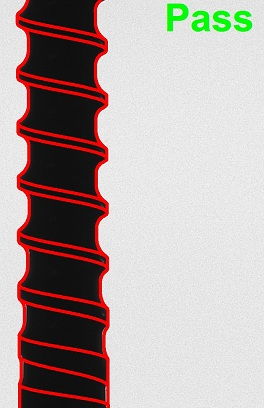

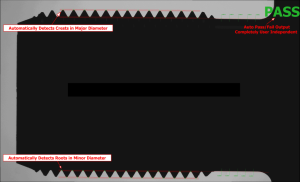

The VisionGauge® Digital Optical Comparator is widely used by medical device manufacturers for automated orthopedic/medical bone screw inspection and measurement.

VisionGauge® introduces several unique benefits in its application to medical bone screw measurement and inspection, including:

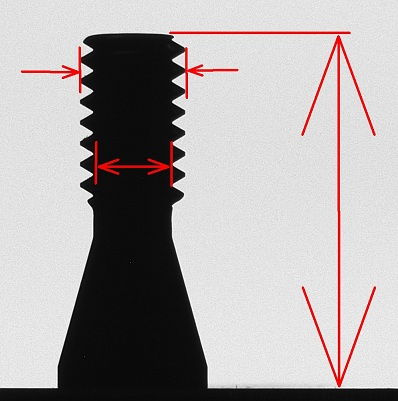

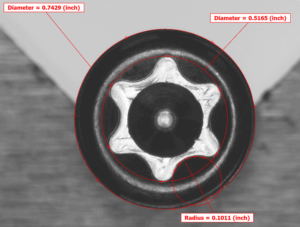

Orthopedic bone screws are made up of different features, with the principal features comprised of the head, thread, and tip. Different requirements apply to each feature to ensure proper overall performance of the screw. These diverse requirements can considerably complicate the inspection of bone screws. However, VisionGauge® can easily check 100% of the features over the entire screw, including its threads, head, and tip.

The importance of proper bone screw measurement and inspection, both during the manufacturing process and at final inspection, cannot be overstated. Proper inspection allows bone screw manufacturers to ensure correct performance, conformance to specifications, and reduced variability of the final product. Furthermore, real-time inspection and measurement with VisionGauge® allows medical manufacturers to optimize the manufacturing process, reduce overall manufacturing costs, improve process control and enable process & part improvement. VisionGauge®’s statistics, data collection & exchange, and reporting provide manufacturers with product traceability and device history.

VisionGauge® is capable of measuring 100% of the screw’s critical dimensions and features, including:

Finally, a dedicated complete dual-rotary assembly, designed specifically for the fully automated inspection and measurement of bone screws, is also available. It allows the full rotation of the screw (to check run-out, for example), its orientation at the helix angle, etc… This package also includes dedicated workholding (either pneumatic or manual) compatible with bone screws that have a thru hole as well as those without. When fitted with a pneumatic chuck, this dedicated dual-rotary assembly allows VisionGauge® to be used in a fully-automated bone screw manufacturing cell, with robot loading and unloading, for complete “lights out” operation.

There exists a wide range of orthopedic screws and they are often named after the type of bones in which they are inserted during the surgery. A few common types include:

With their wide range of measurement tools and great flexibility, VisionGauge® Digital Optical Comparators are the perfect tools for inspecting and measuring 100% of the features on all of the different types of bone screws.

Orthopedic screws can be made of different materials and have a wide range of coatings. Titanium, stainless steel and bio-absorbable materials, that get absorbed by the body over time, are the most common types of materials for bone screws. By design, bone screws require hard-to-machine materials. This only compounds the difficulties involved in machining their complex threads. This further increases the importance of complete and proper inspection and measurement of bone screws throughout their manufacturing process, for proper control. With its flexible illumination modules and powerful adaptive measurement tools, VisionGauge® has no problem accommodating any of the variations in bone screw material and finish.

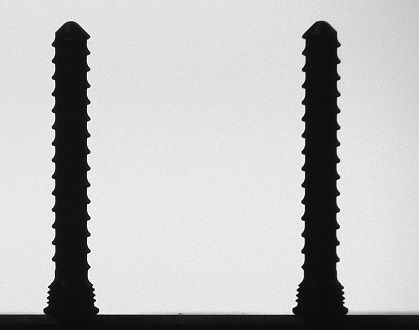

For inspection and measurement of orthopedic screws on the VisionGauge® Digital Optical Comparator, some manufacturers use horizontal configurations, while others use a vertical configuration. The decision to use one or the other is generally based on fixturing considerations. The hard chrome plated stage, made from hardened tooling steel, has industry standard dual dovetail grooves that make it compatible with existing mounting fixtures, and a drop-in replacement for traditional optical comparators. Rotary stages are also an option that can be added to these systems.

The VisionGauge® Digital Optical Comparator is the new standard in measuring and controlling the geometry of medical/orthopedic bone screws. Screw manufacturers can ensure their product has good dimensional accuracy and surface finish while also significantly reducing inspection times and overall cost. Operator-to-operator variation is entirely eliminated with this system, and manufacturers are capable of automatically collecting accurate screw dimensions and inspection result data, computing process statistics, and automating complete inspection reports. The VisionGauge® Digital Optical Comparator is an invaluable tool for process control and quality improvement, and it represents a significant advantage in modern competitive medical markets for bone screw manufacturers.

Download a .pdf version of this VisionGauge® Digital Optical Comparator Application Note.

Are you interested in streamlining your inspection process with VisionGauge® Digital Optical Comparators and optical measuring systems? As your vision inspection system manufacturer, we’re available to provide support at any time, so browse our selection of products or contact us online today.

Learn More