VisionGauge® for Fast, Accurate, and Robust Inspection & Measurement of Medical Intramedullary Nails

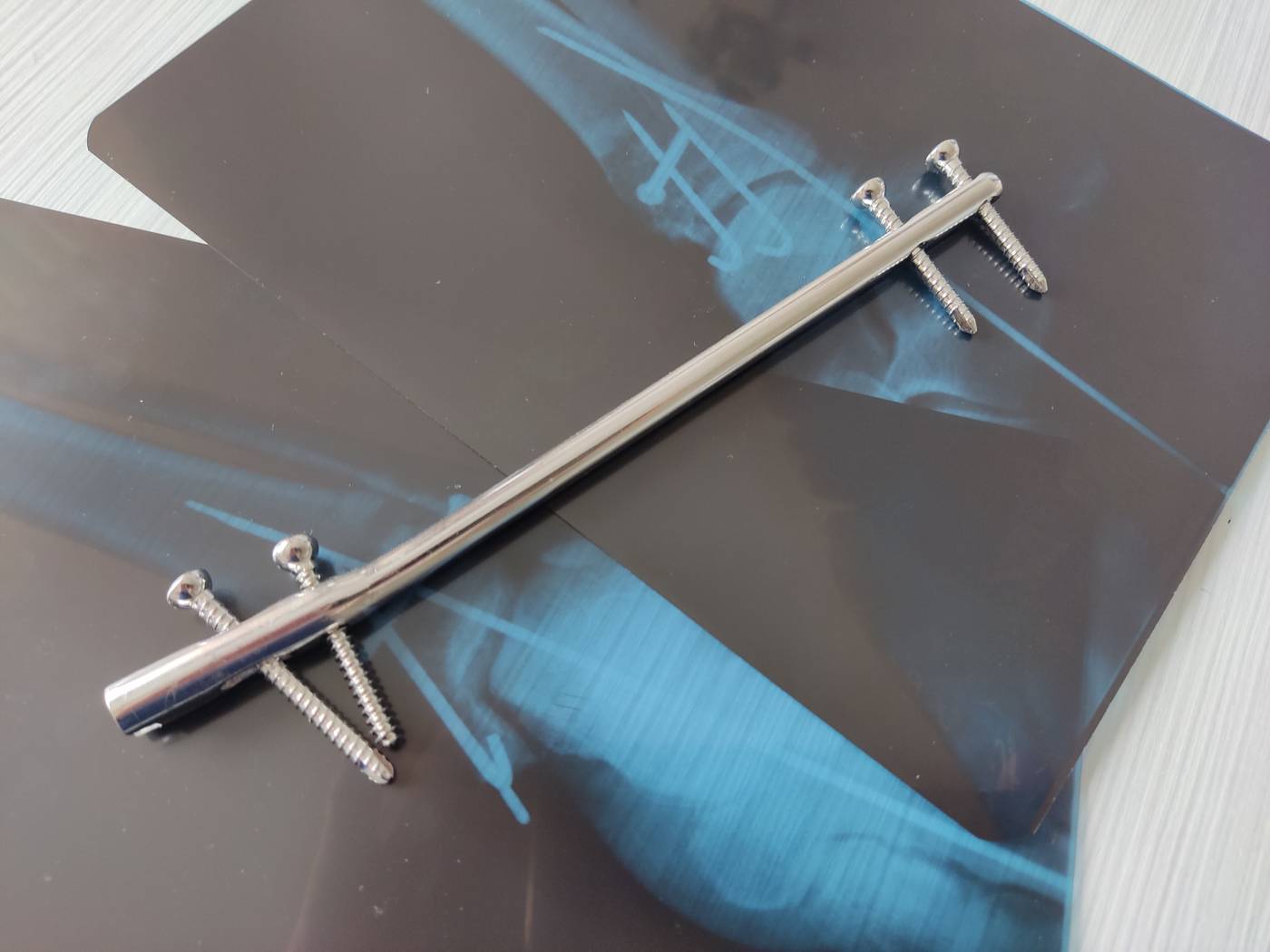

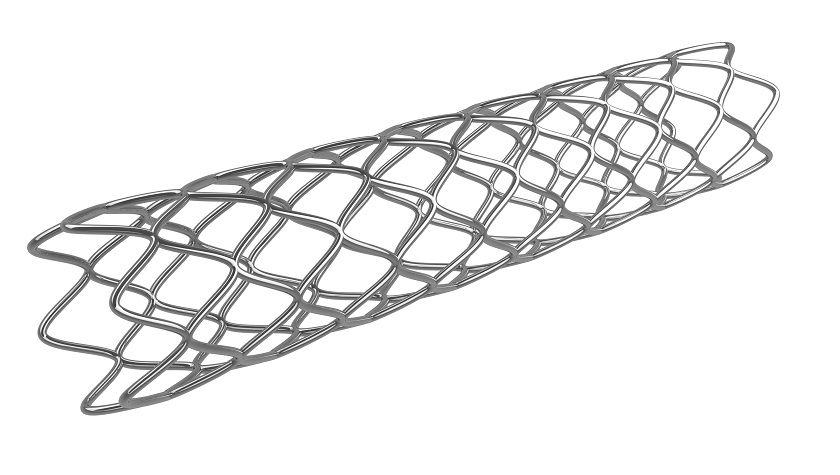

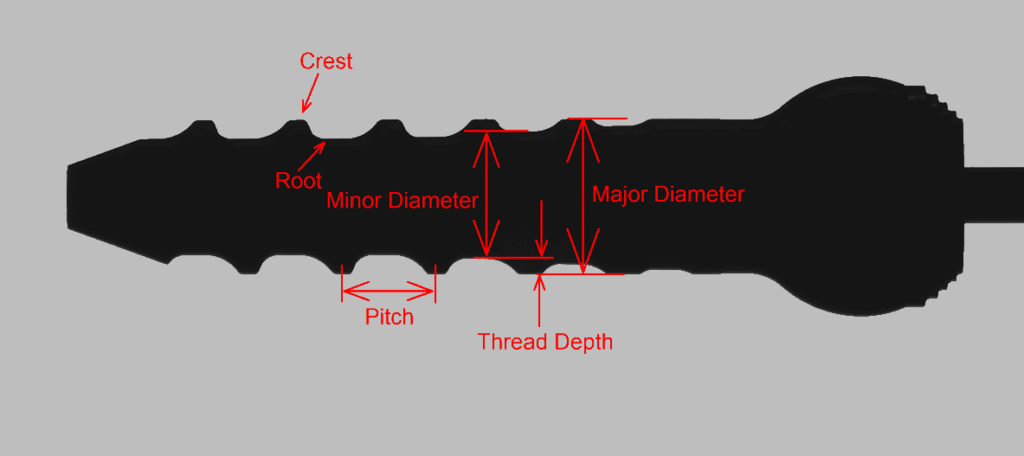

Intramedullary (IM) nails have long been used to treat fractures of long bones in the human body. An IM nail is a metal rod forced into the medullary cavity of a bone. IM nails are most often made of titanium, which provides low mechanical failure rates and good biocompatibility.

The fractures in which IM nails are used are inherently unstable. So-called ‘locking’ nails, which are now the standard, use bolts on each end of the nail to fix it to the bony cortex, thus preventing collapse or rotation between the bone fragments.

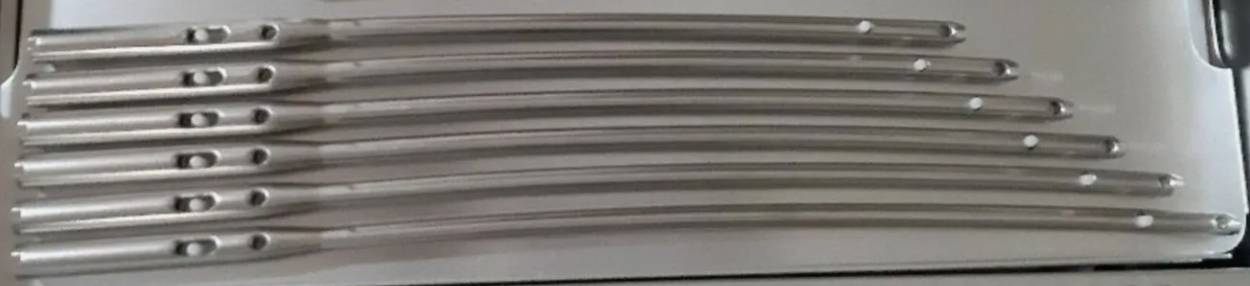

IM nails are widely used and provide an efficient, practical solution for treating a wide range of fractures (including shoulder, humerus, elbow, hip, femur & tibia…). As such, they are available in a very wide range of lengths, sizes and geometries. Also, for a given nail type and model, a variety of diameters and lengths are generally available, to accommodate varying patient anatomy.

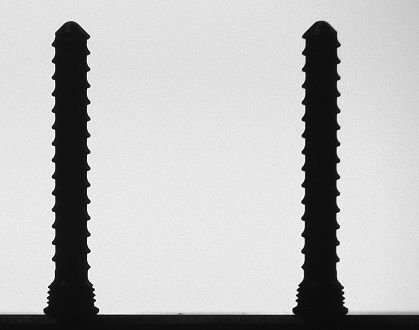

VisionGauge® Can Inspect Nails of Any Size

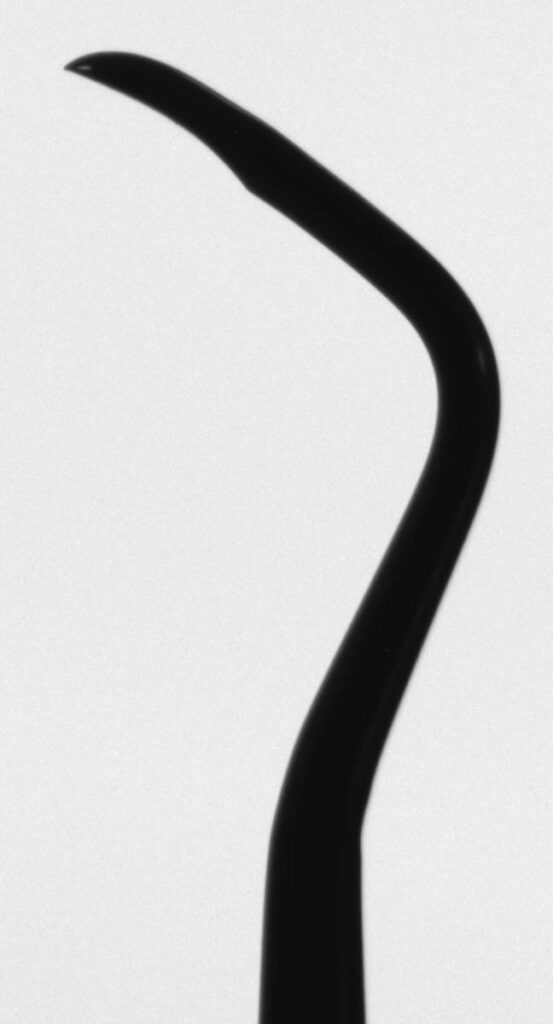

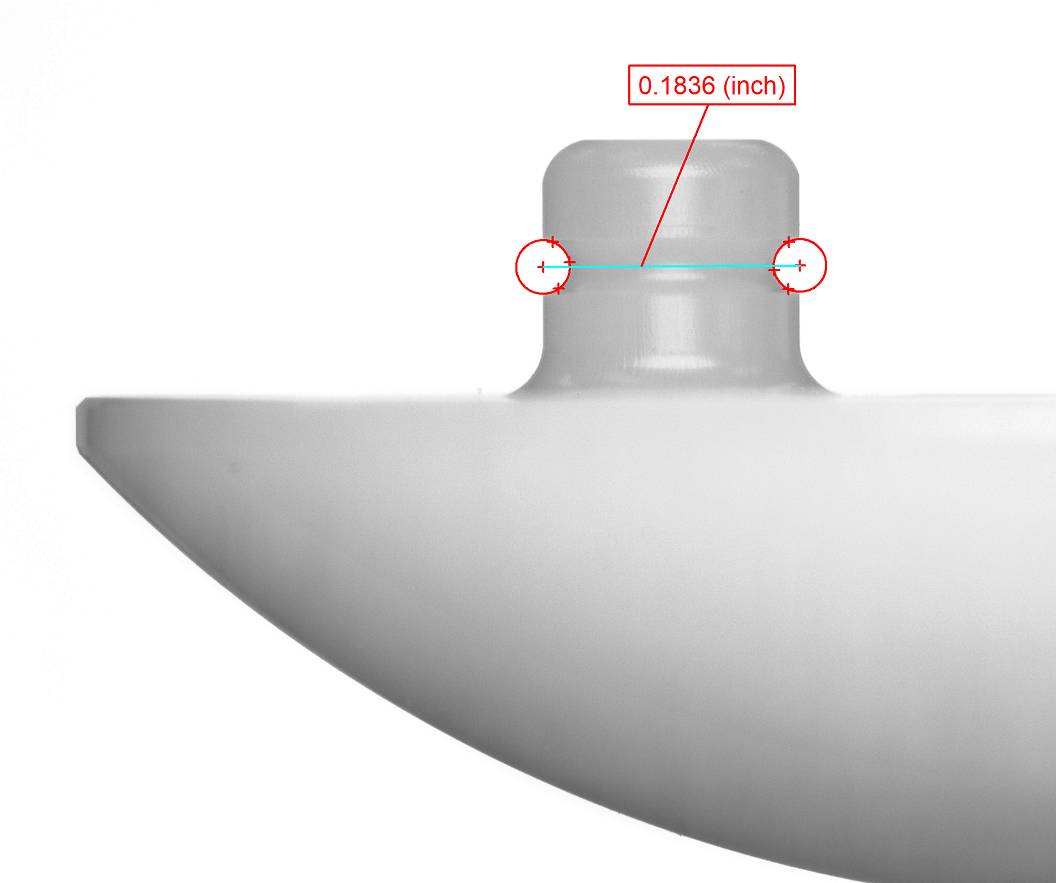

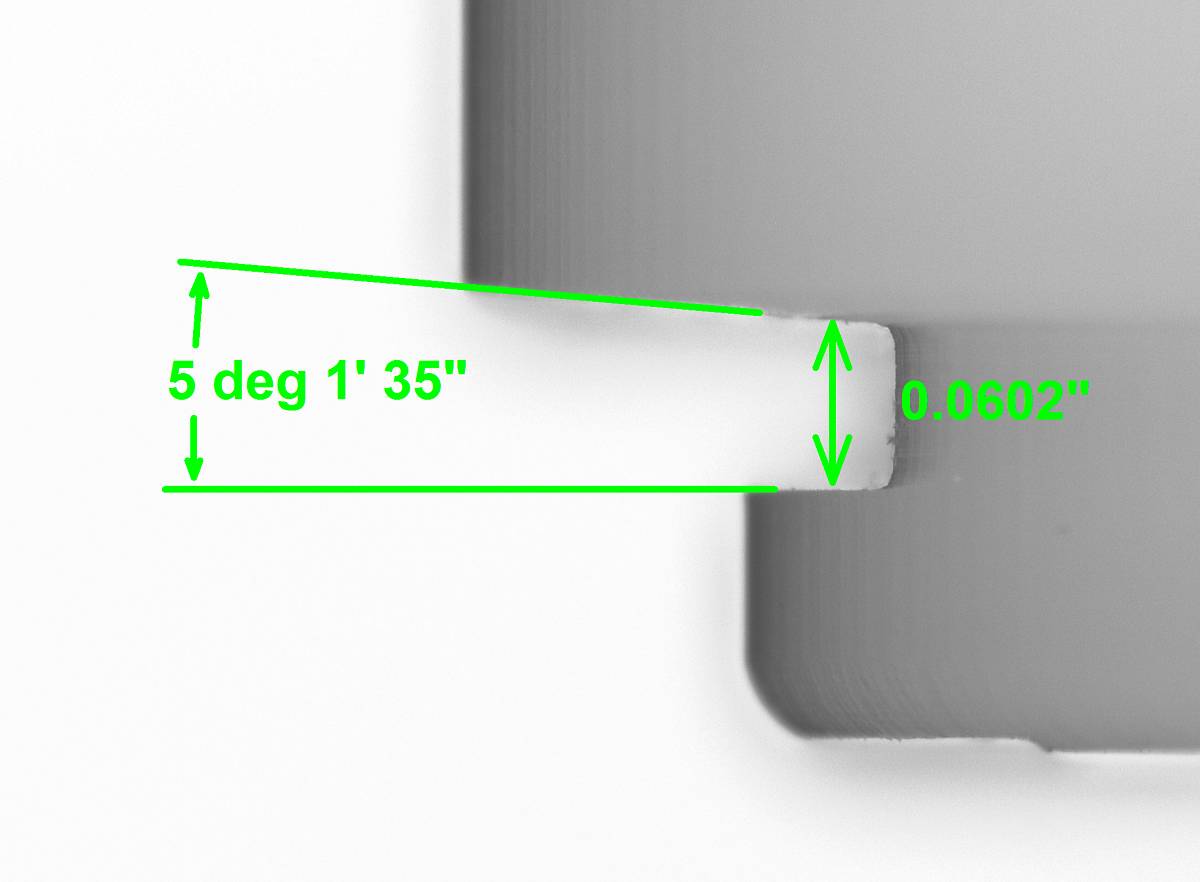

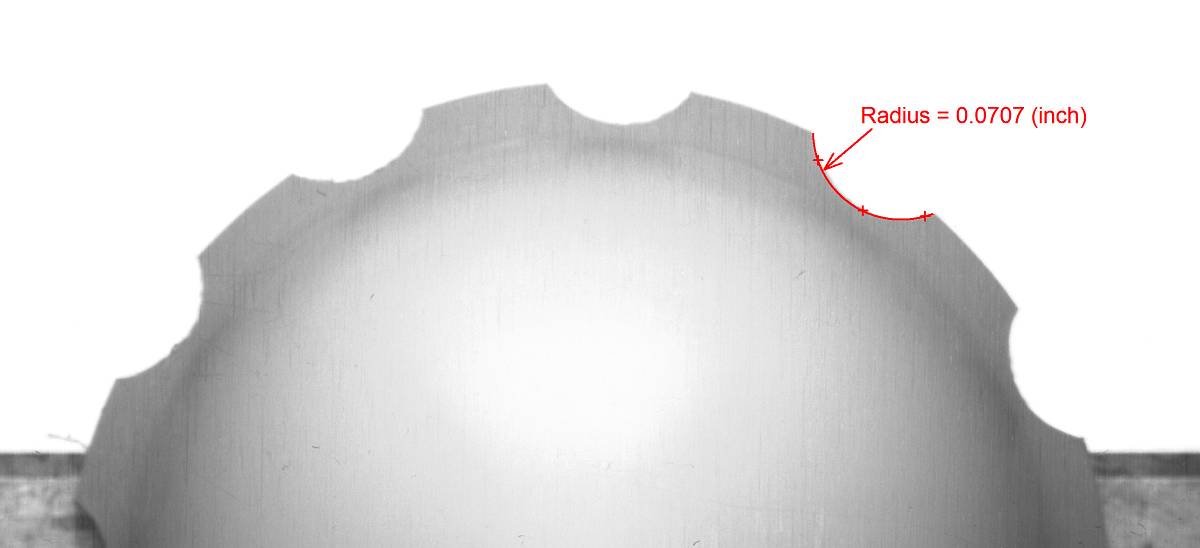

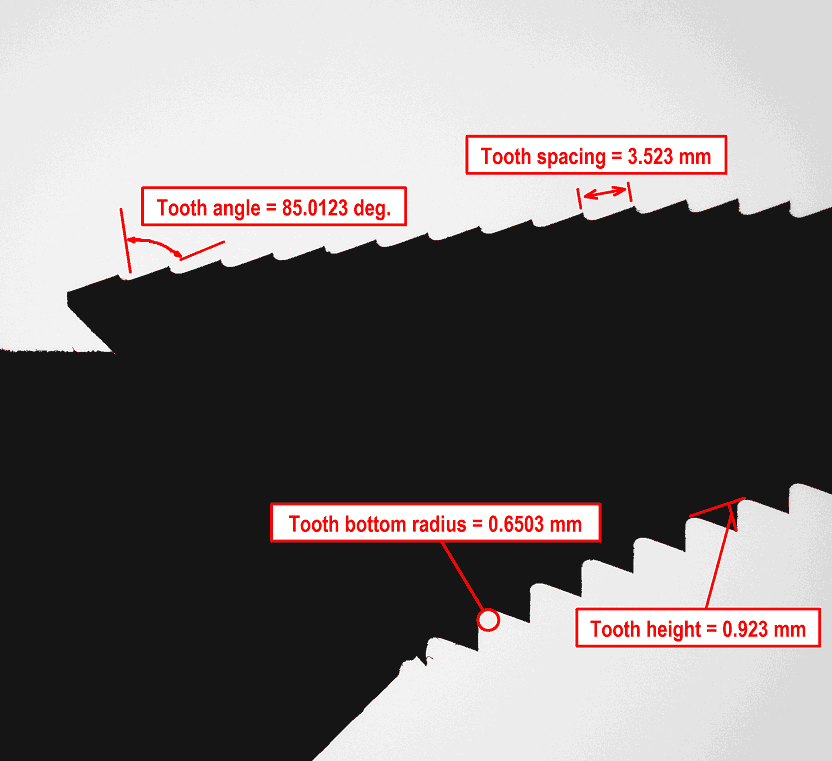

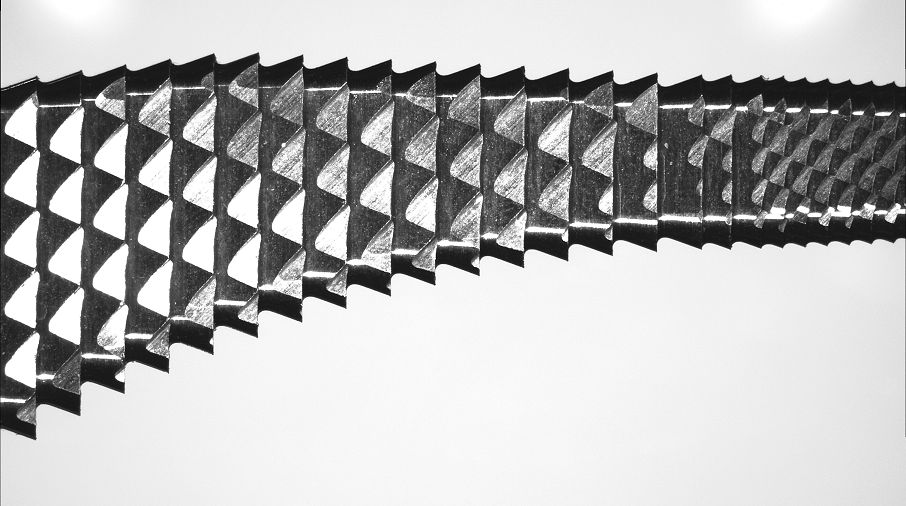

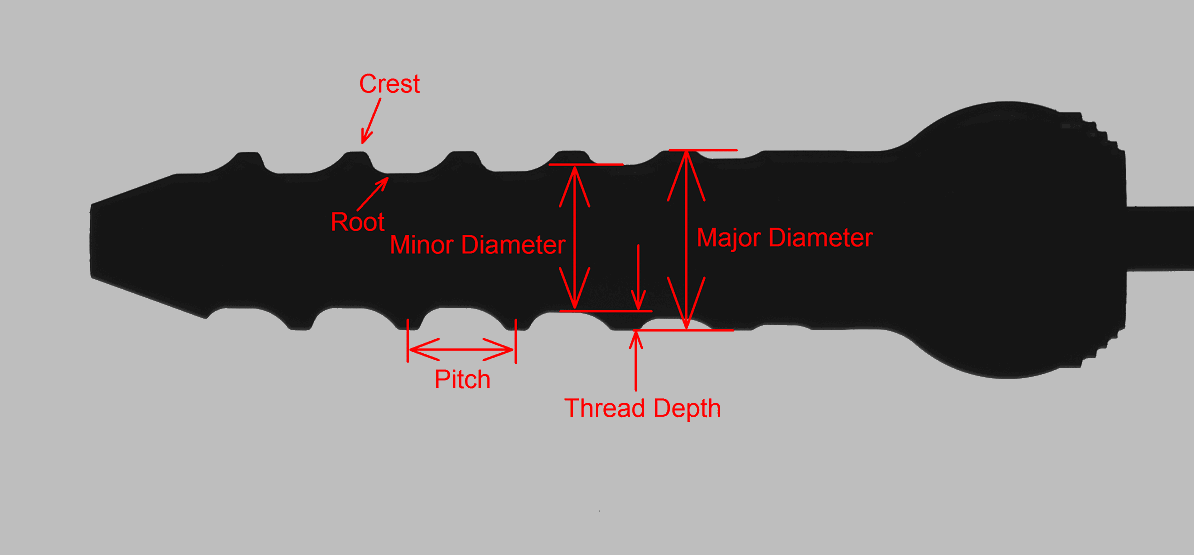

Each nail is designed to be used in a very specific application to closely replicate the fractured bone’s pre-injury state. Nails often have bows that correspond to the bow of the natural bone. They can present a fluted design to moderate stiffness and facilitate nail placement. And nail tips are often designed to help the passage of the nail through the medullary canal. Finally, many nail systems include both left and right versions.

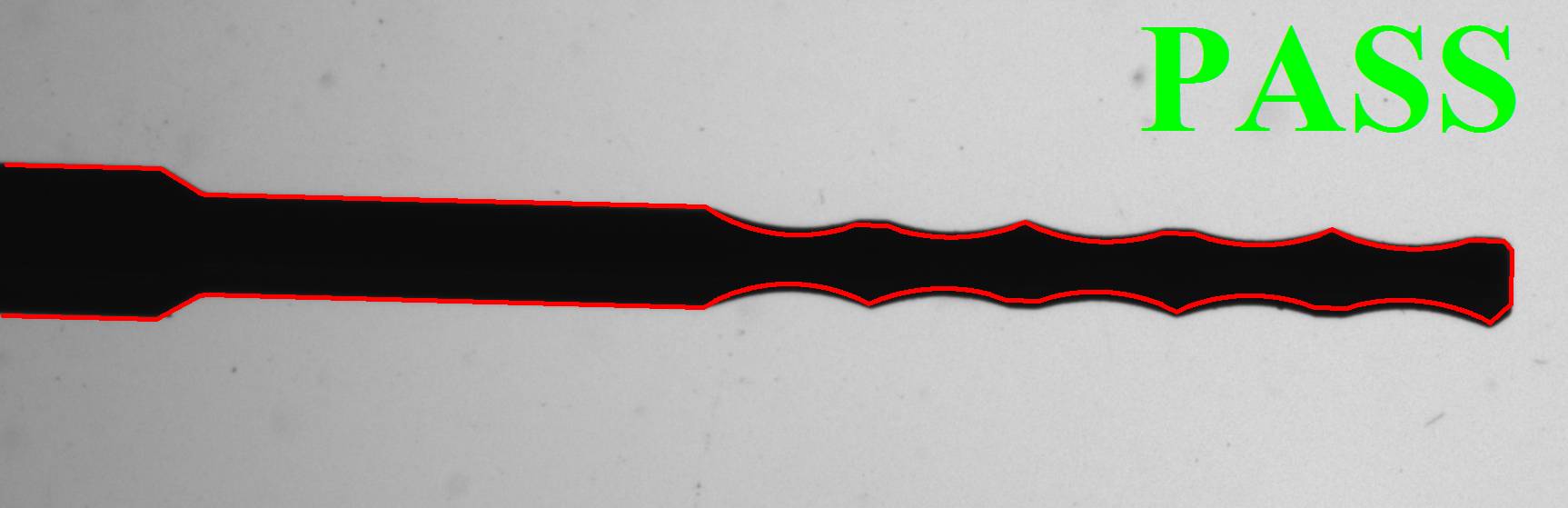

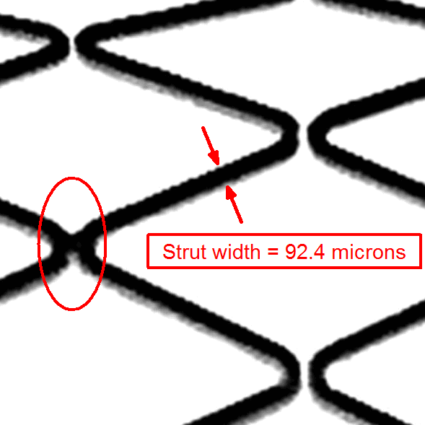

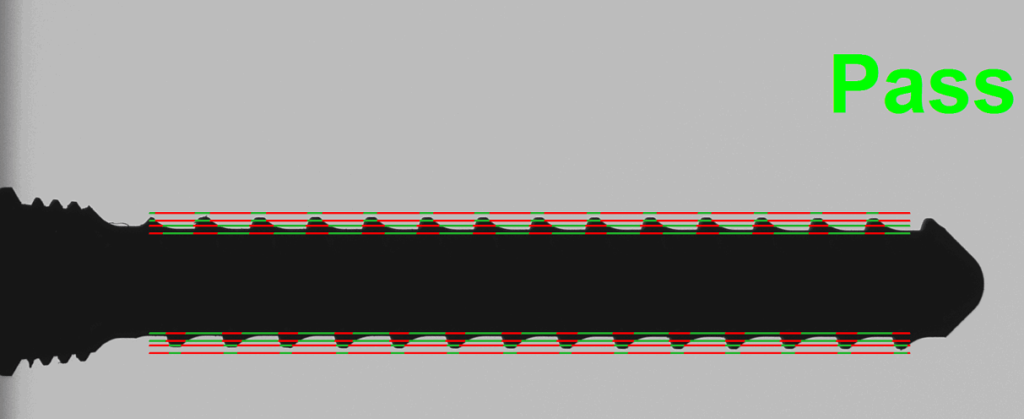

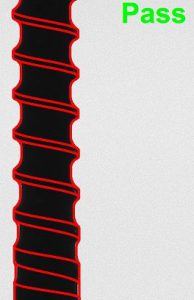

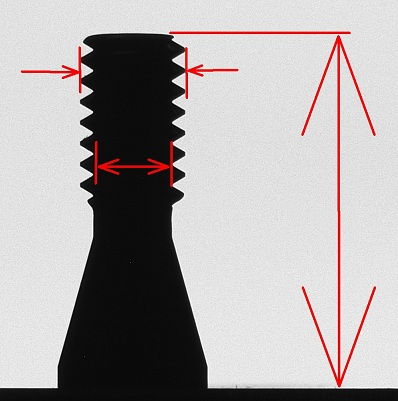

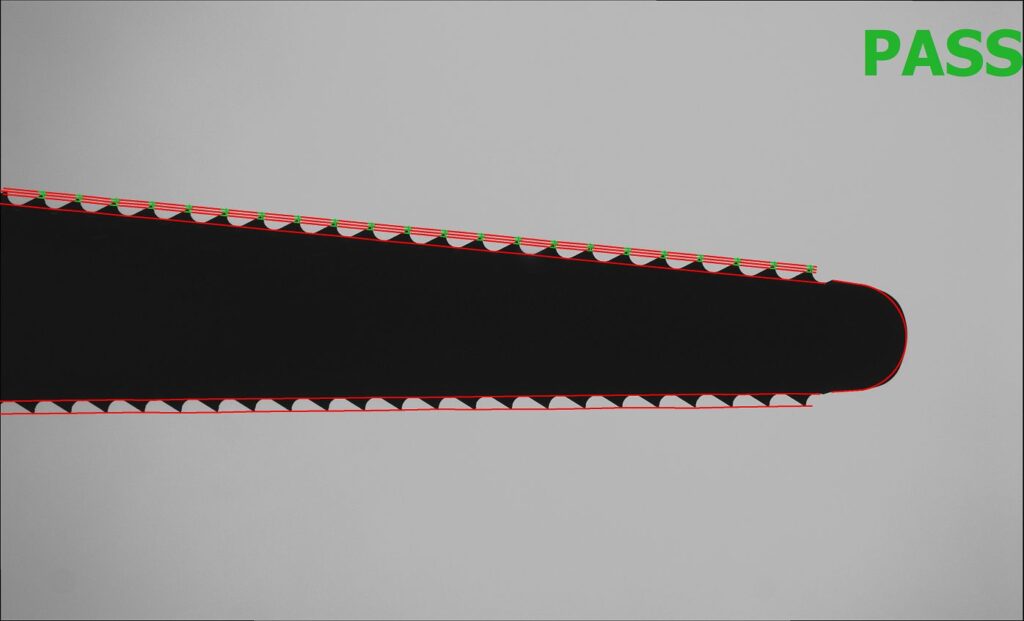

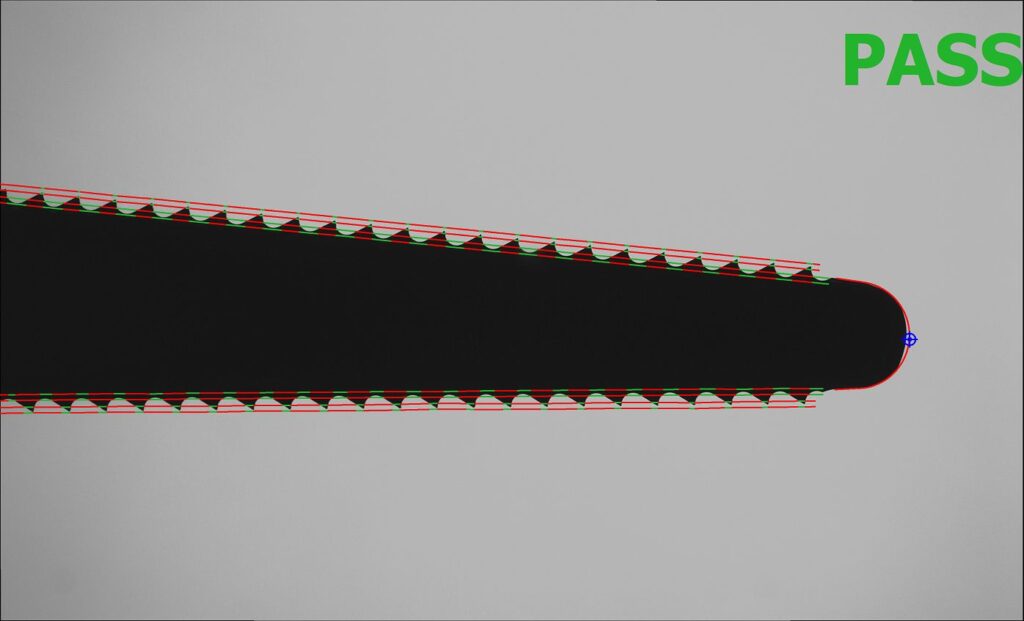

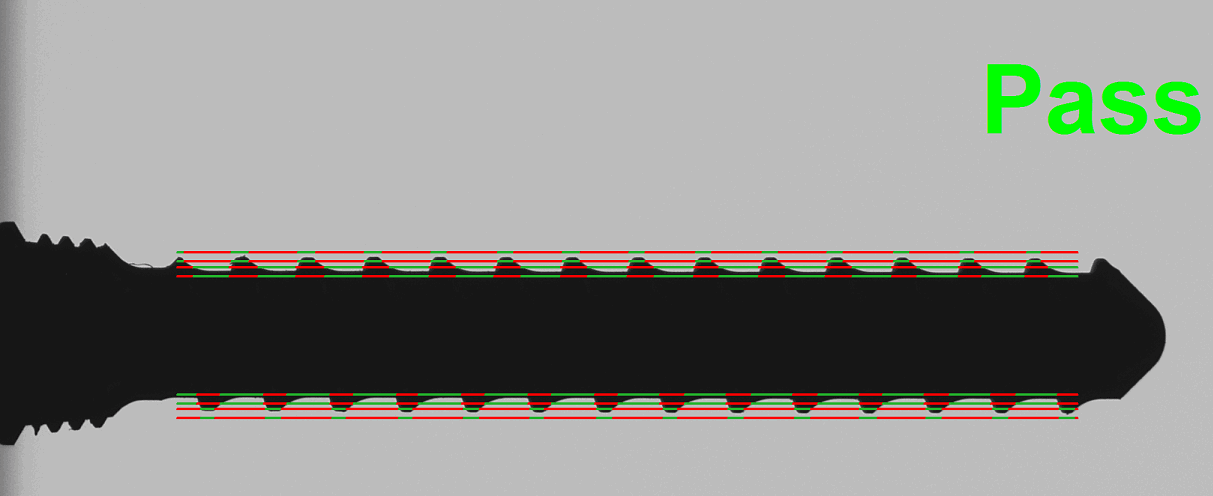

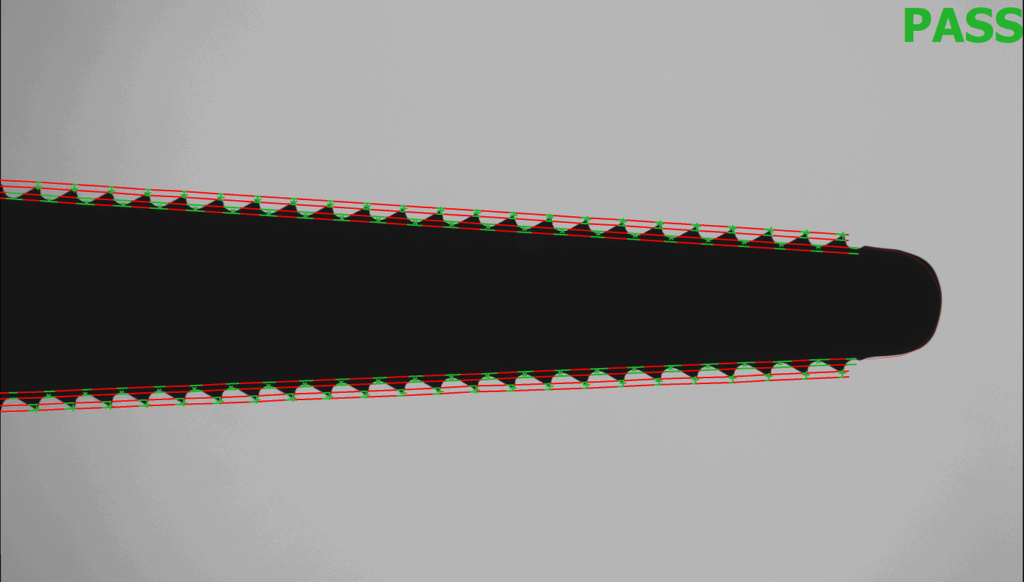

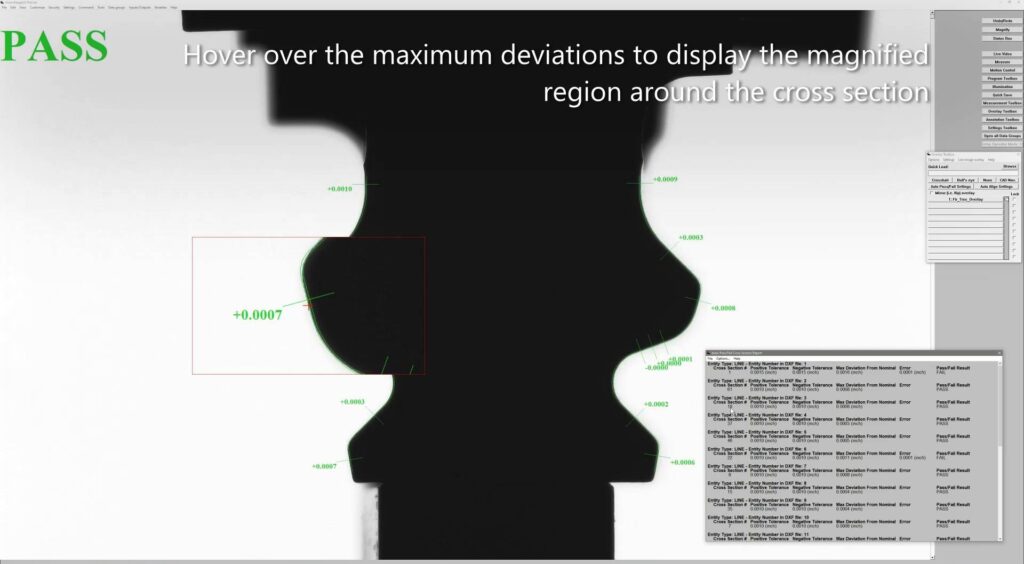

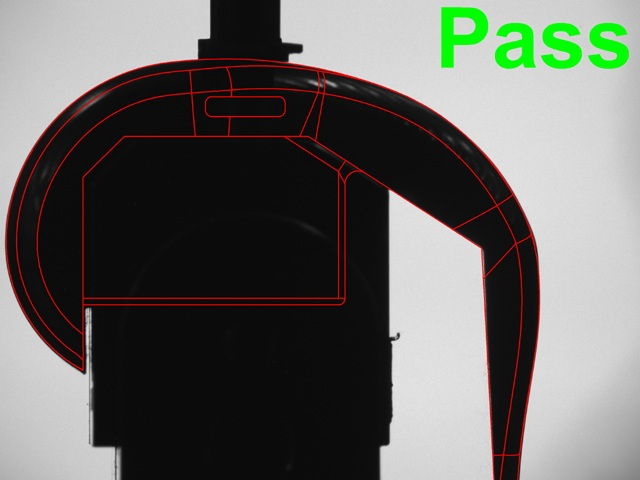

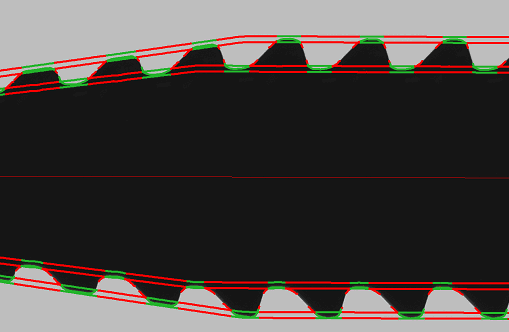

These product variations combined with their complex geometries and anatomic shapes make the inspection of medical nails very challenging. With VisionGauge®, these long parts don’t need to be inspected section-by-section like they were with traditional optical comparators. This provides a significant advantage. With VisionGauge®, the entire part can be inspected in its entirety, because the overlay tracks the part as it moves across the stage travel. This means that VisionGauge® is not limited by the length of the IM nails in any way.

The facts that VisionGauge® requires no programming and can very quickly change from one job to the next (& back…) are also huge advantages for this application. VisionGauge® can also inspect the fixation devices and instruments that often accompany the nails, which is another significant benefit.

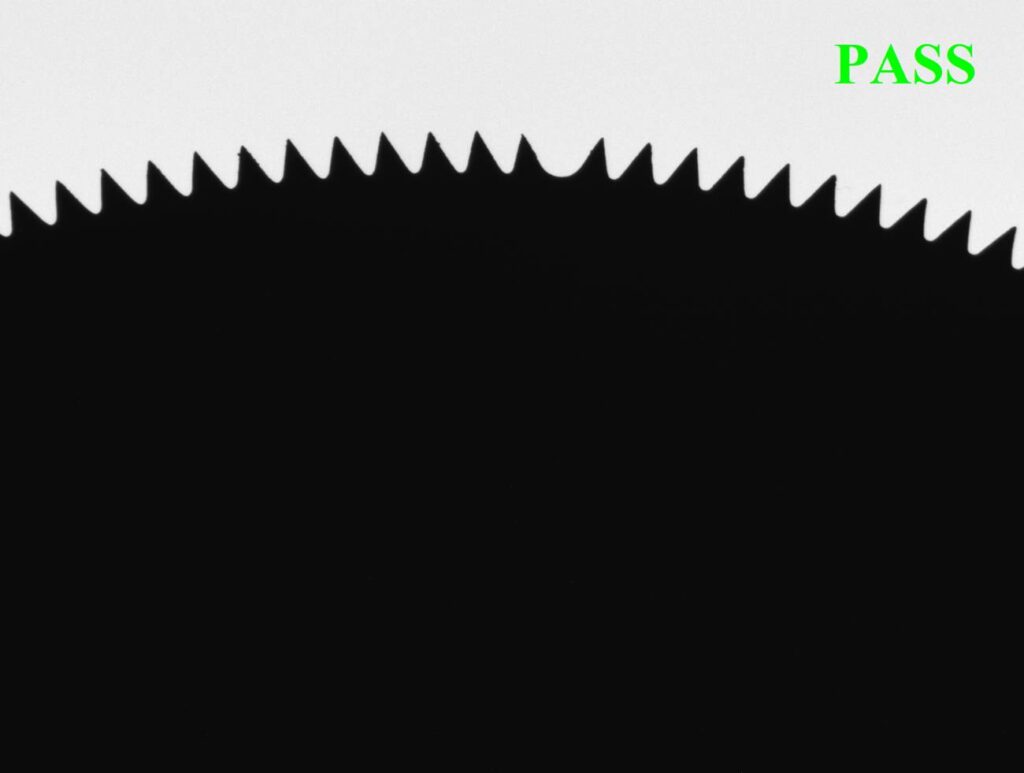

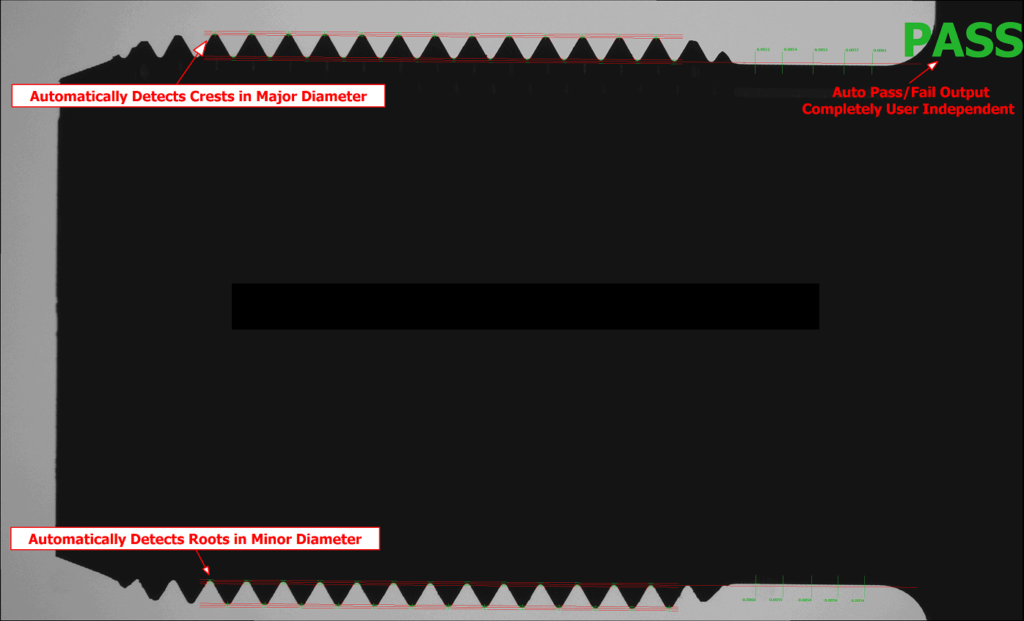

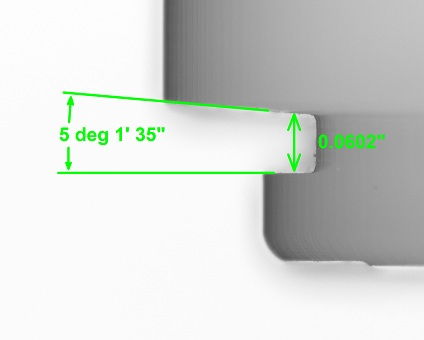

Furthermore, for fast and accurate inspection of intramedullary nails, the VisionGauge® patented CAD Auto-Align™ and CAD Auto-PASS/FAIL™ tools are real “game-changers” as they produce fast and repeatable operator-independent results.

Finally, VisionGauge® can be used to carry out complete data capture, compute statistics, create reports and collect device history, directly on the shop floor.

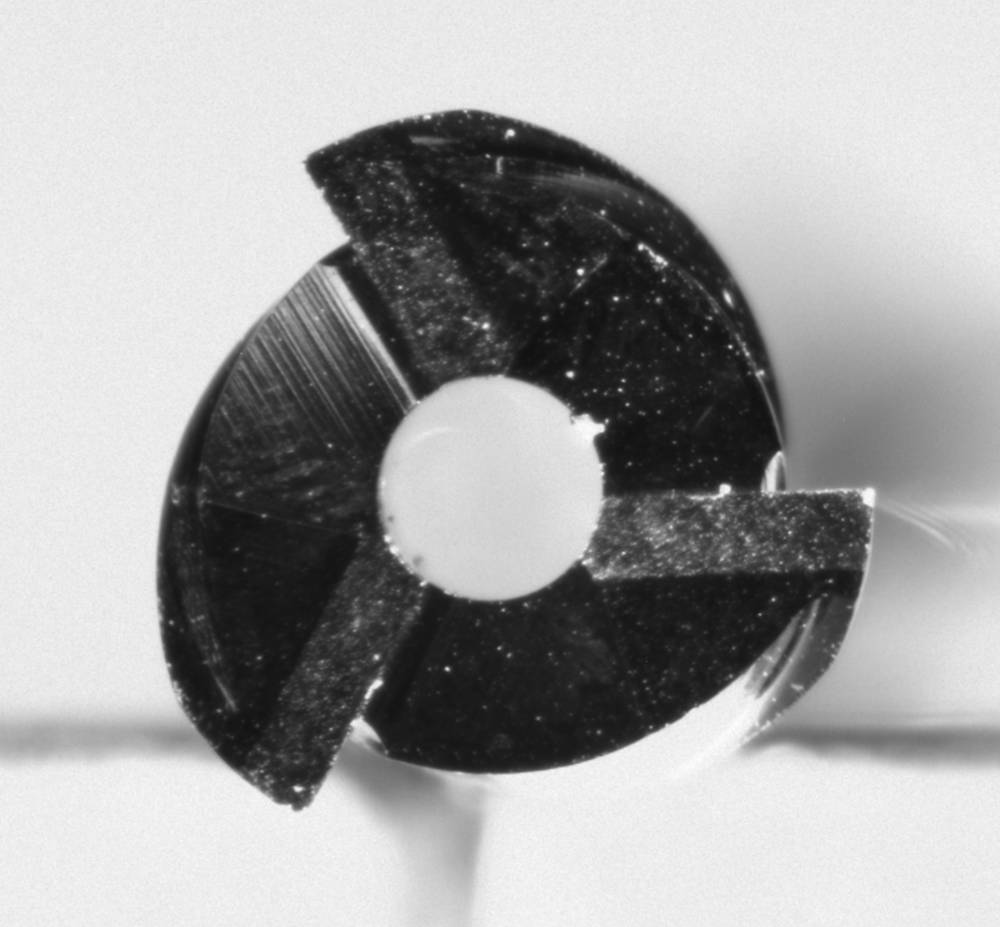

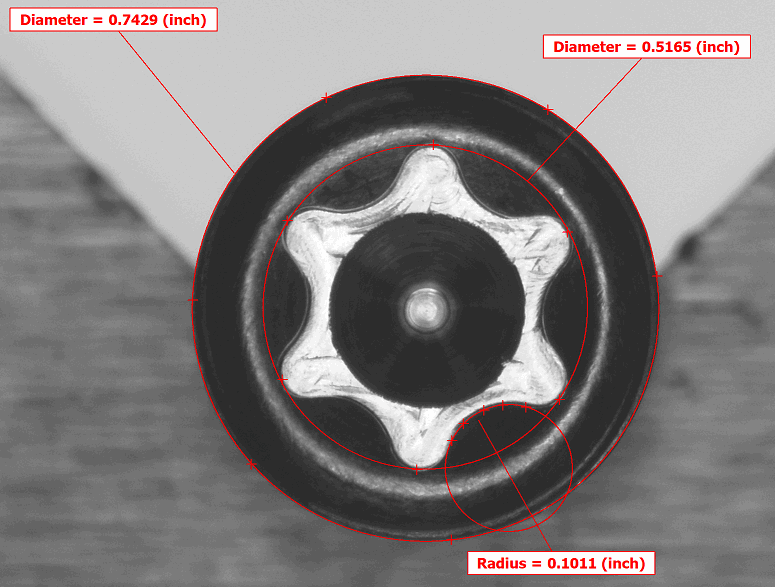

VisionGauge® can also be used to verify the anti-rotation holes, locking tabs and other features of IM nails.

With all of its advanced, up-to-date technology, the 500 Series VisionGauge® system really is the ideal solution for the inspection and measurement of medical intramedullary nails.

Download a .pdf version of this VisionGauge® Digital Optical Comparator Application Note.