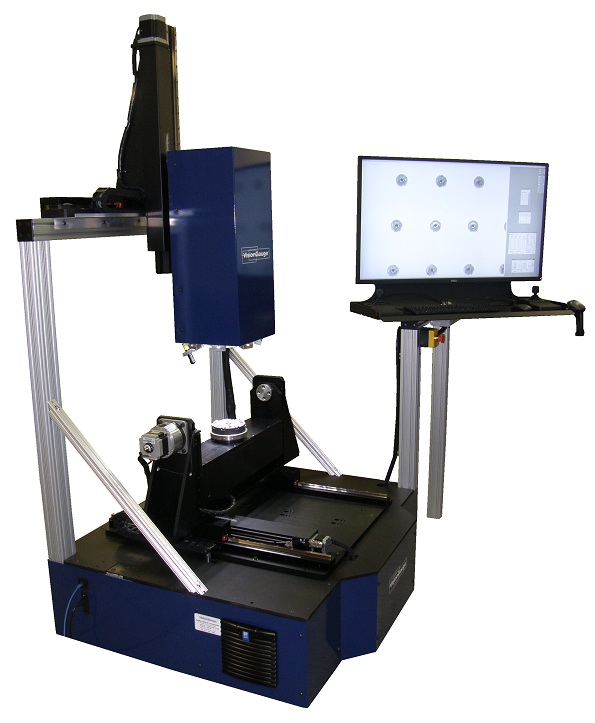

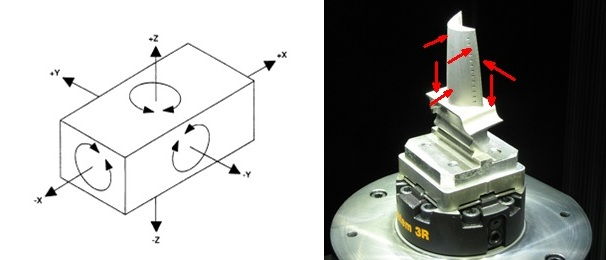

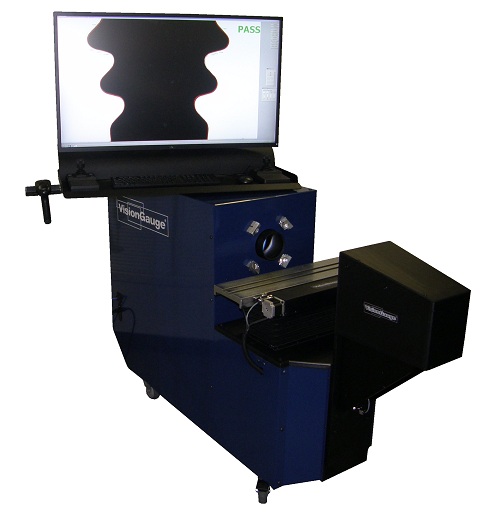

The VisionGauge® Digital Optical Comparator’s new “Min/Max” software tool is the perfect solution for automatically aligning a part using a rotary stage. The tool can be setup to rotate the part and find the position that either minimizes or maximizes a dimension.

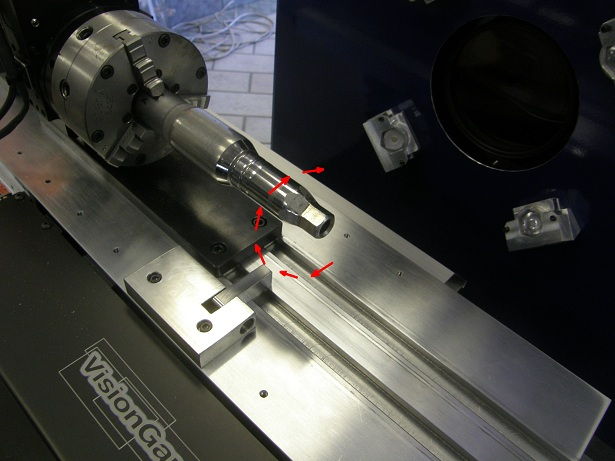

Common examples include the following:

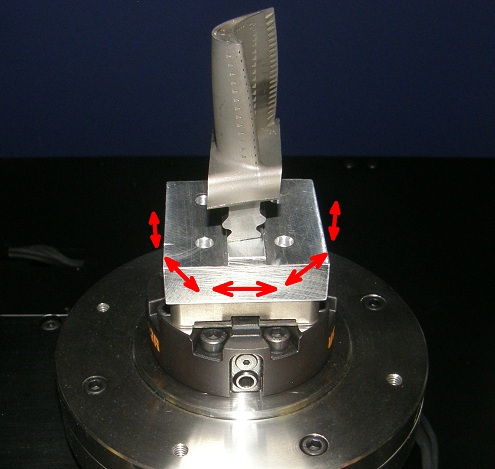

In this case, the Min/Max tool is used to align the flats on the part perfectly horizontally, completely automatically

With this new Min/Max tool, it’s extremely easy to setup an automated routine for the alignment of any kind of part. Also, results are extremely repeatable. This advanced tool uses high-order interpolation for very accurate subsampling. This means that the position of best alignment can be found very accurately, at any orientation (not just at the sampled orientations).

This new tool is completely integrated with all of the VisionGauge® Digital Optical Comparator’s other tools so that all of its results can easily be recoded, transmitted, databased, sent to Excel™ or any other data capture application, put in a report, etc…

This new Min/Max tool further increases the wide range of applications that can easily and reliably be solved using the VisionGauge® Digital Optical Comparator.

Click to view this application note as a downloadable .pdf.