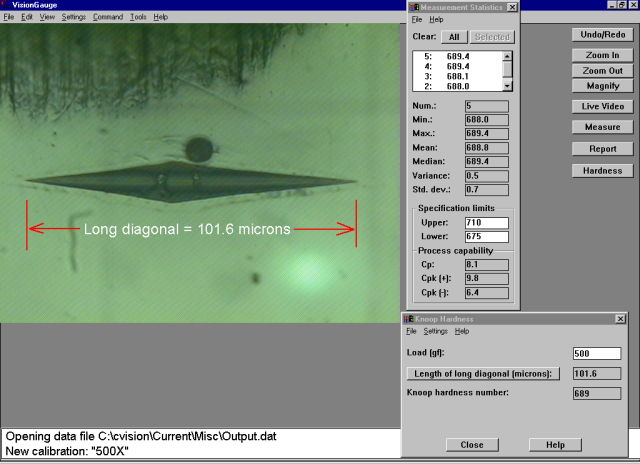

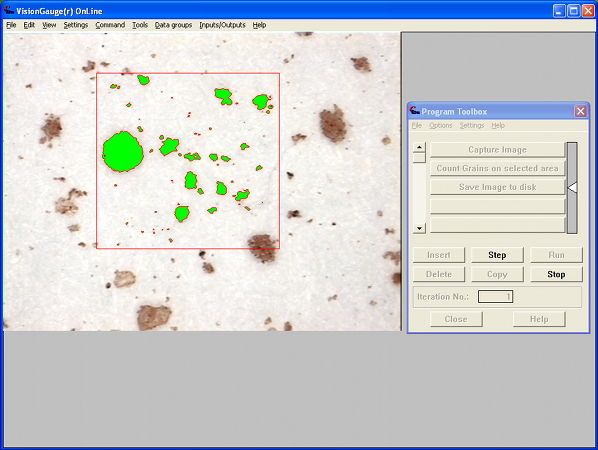

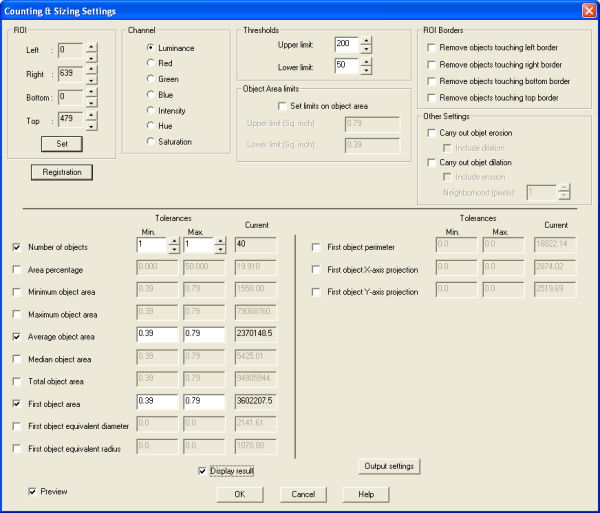

VisionGauge® OnLine Counting and Sizing (Blob Analysis) tools are able to automatically locate, count, and size grains, cells, or particles of any shape or size present on an image. You are also able to specify a region of interest so only a desired area on the image is considered. The image can be analyzed in various colour channels such as: Luminance, Hue, Saturation and the different Gamma colors. Selecting objects in the field of view using these channels greatly enhances your ability to produce extremely accurate results.

Thresholds are used to better analyze the image. Different thresholds would be applied if the grains are dark on a light background, or red on a blue background, etc. VisionGauge® OnLine lets you customize these threshold values to assure the best results. You can also program a threshold to count objects that are close together so they are considered as one object or more.

You can also program the tool to filter out objects of certain sizes. Therefore, you can count/size only those objects that fit a certain size profile, eliminating spurious objects from your results.

All of VisionGauge® OnLine’s image processing and analysis tools are available to automatically “cleanup” the image before carrying out the particle counting or grain sizing operation. This can dramatically improve results in the cases where there is contamination, background noise, etc.

VisionGauge® OnLine’s Counting & Sizing Tool can perform various calculations and grain measurements including:

- The total number of particles

- The minimum particle area

- The maximum particle area

- The average particle area

- The median particle area

- The total particle area

- and more…

No matter the type of application dealing with counting and sizing particles, cells, grains, etc., VisionGauge® OnLine’s Counting & Sizing Tool is a powerful, versatile solution delivering accurate and reliable results.

Information is also available about more recent applications solved with our complete selection of VisionGauge® Digital Optical Comparators.

VisionGauge® OnLine

VisionGauge® OnLine  With the

With the