VisionGauge® OnLine Automated Optical Inspection Systems (AOI systems) are fully-automated 3D inspection and measurement systems capable of delivering high-accuracy results for various applications and industries. Many different configurations are available, depending on the requirements of the application. New to AOI? Learn more in our guide to AOI.

VisionGauge® Online High-Speed Automated Optical Inspection systems are the ideal solution for demanding high-throughput, high-resolution applications. These systems are suitable for a wide range of applications requiring automated defect detection and high-accuracy measurements, including MicroElectroMechanical systems (for MEMS inspection or MEMS measurement), semiconductor and discrete device inspection and measurement, and much more.

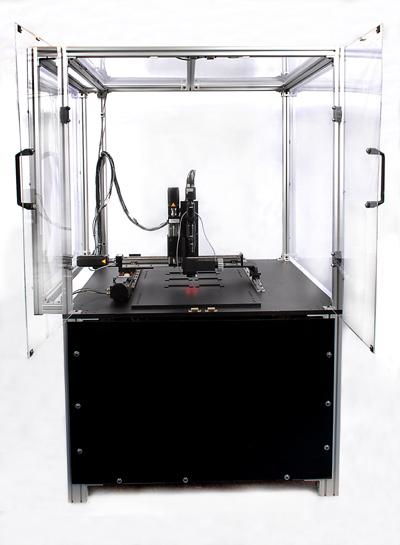

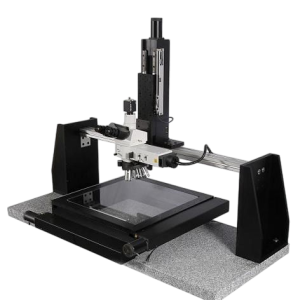

VisionGauge® Online High-Speed AOI machines are multi-processor based automated inspection systems that support concurrent image analysis and stage motion. It is a complete, fully-contained, self-standing unit in a full gantry configuration (i.e. the camera moves over the parts; the parts themselves do not move).

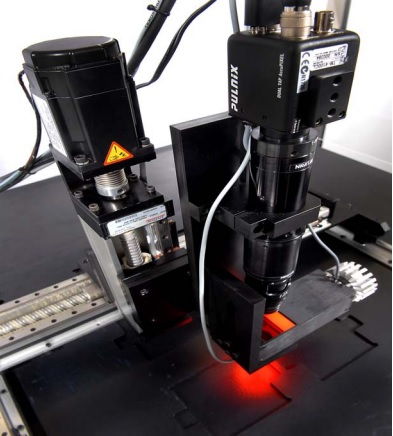

These systems are available with a resolution as fine as 0.1 micron. Multiple customizations are possible to meet application-specific requirements including modifications to the camera, optics, illumination module, fixtures, and more. An optional LASER module for automated laser profiling can also be integrated. We provide a wide range of travels, short and long, and a high-speed 240 VAC servomotor motion system for rapid, accurate positioning.

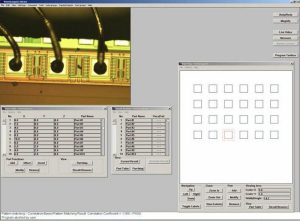

VisionGauge® Online High-Speed Automated Optical Inspection machines are powerful, but easy to use and easy to program. Fully-automated inspection and measurement programs (i.e. “recipes”) are created and modified using VisionGauge®’s intuitive Graphical User Interface. Programs can be saved to disk and read-in later on, allowing the possibility to manage different inspection routines for different parts.

Sample videos:

Head-on view

Oblique view

Download a pdf with more information about the VisionGauge® High-Speed, High-Accuracy (AOI) Automated Optical Inspection System.

Our automated optical inspection equipment features high-precision, crossed-roller movements with 0.1 micron encoder feedback and micro-stepping motor controller capable of ultra-fine movements. All axes can be automated and are controlled using an external multi-axis, 3-speed joystick or on-screen joystick controls.

The built-in “Auto-Focus” provides fast, accurate, and repeatable re-focusing. With VisionGauge® OnLine’s intuitive ‘teach’ mode, it is easy to create part programs, then let the system perform automated measurements. Programs can be automatically loaded, saved, and read-in from disk so they are ready to operate as soon as the part is in place. VisionGauge® OnLine’s extensive set of measurement tools and “Auto-Scan” feature with advanced detection capabilities are perfect for applications requiring automatic defect detection.

An open-frame stage with a glass insert allows for both transmitted and reflected illumination. Half- and full-bridge configurations are also available – for example, if your application requires heavy loads and long travels. Standard configurations are available ‘off the shelf’ and non-standard configurations can also be easily accommodated: We have a great deal of experience with customization and can configure a system to meet your specific requirements.

Download a pdf with more information about the VisionGauge® High-Speed, High-Accuracy (AOI) Automated Optical Inspection System.

These automated inspection systems are very easy to program. Everything is done using the mouse & joystick, through VisionGauge’s® intuitive graphical user interface making it quick and easy to review results, view images of “pass” or “fail” parts, export data to Excel or any other application, activate built-in SPC (with graphs as well as numerical & pass/fail statistics), etc…

Advanced software tools include:

Our automated optical inspection systems are widely-applicable and include a vast range of analysis and measurement tools to allow you to successfully solve countless inspection and measurement machine vision applications. See how automated visual inspection can help your business.

View more information about applications our AOI systems have been used to solve in various industries. Also, learn about our powerful and adaptable VisionGauge® Digital Optical Comparators and how they can solve your application.