VisionGauge® Digital Optical Comparators for Fast, Easy, and Accurate Hole Array Inspection & Measurement

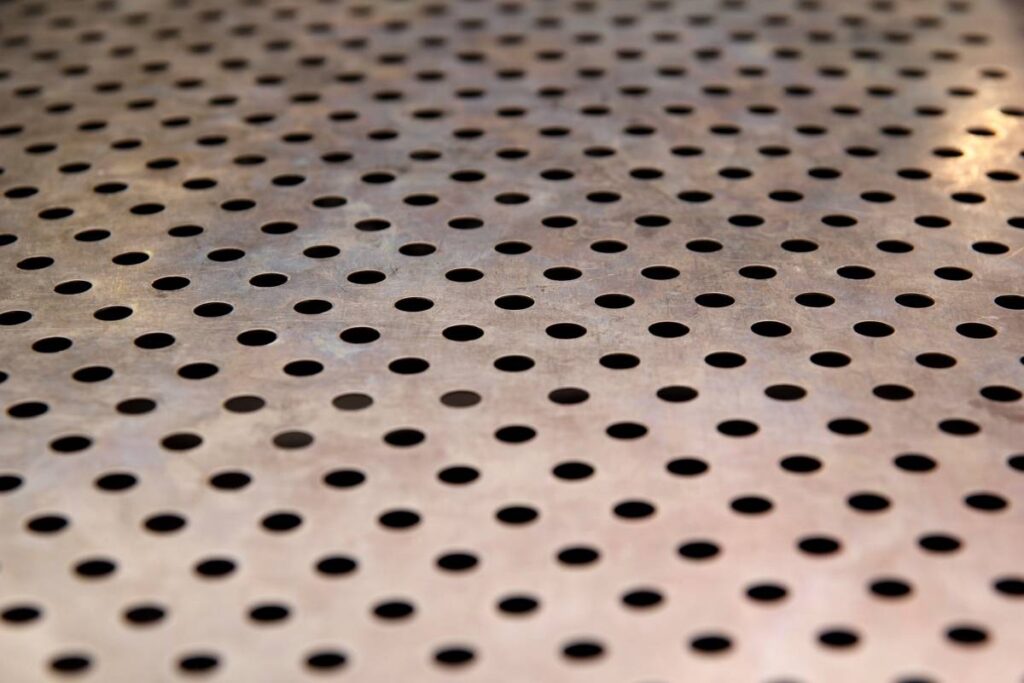

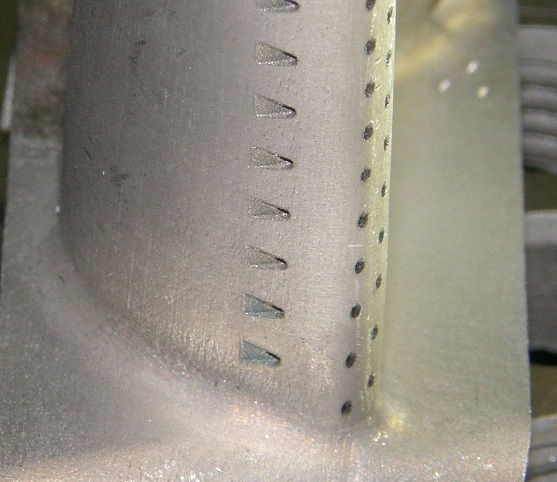

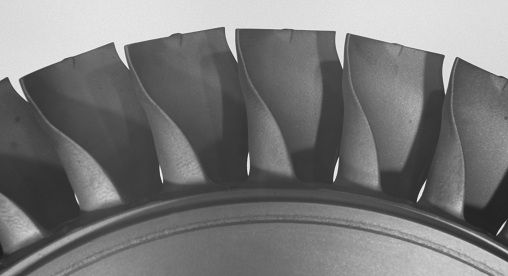

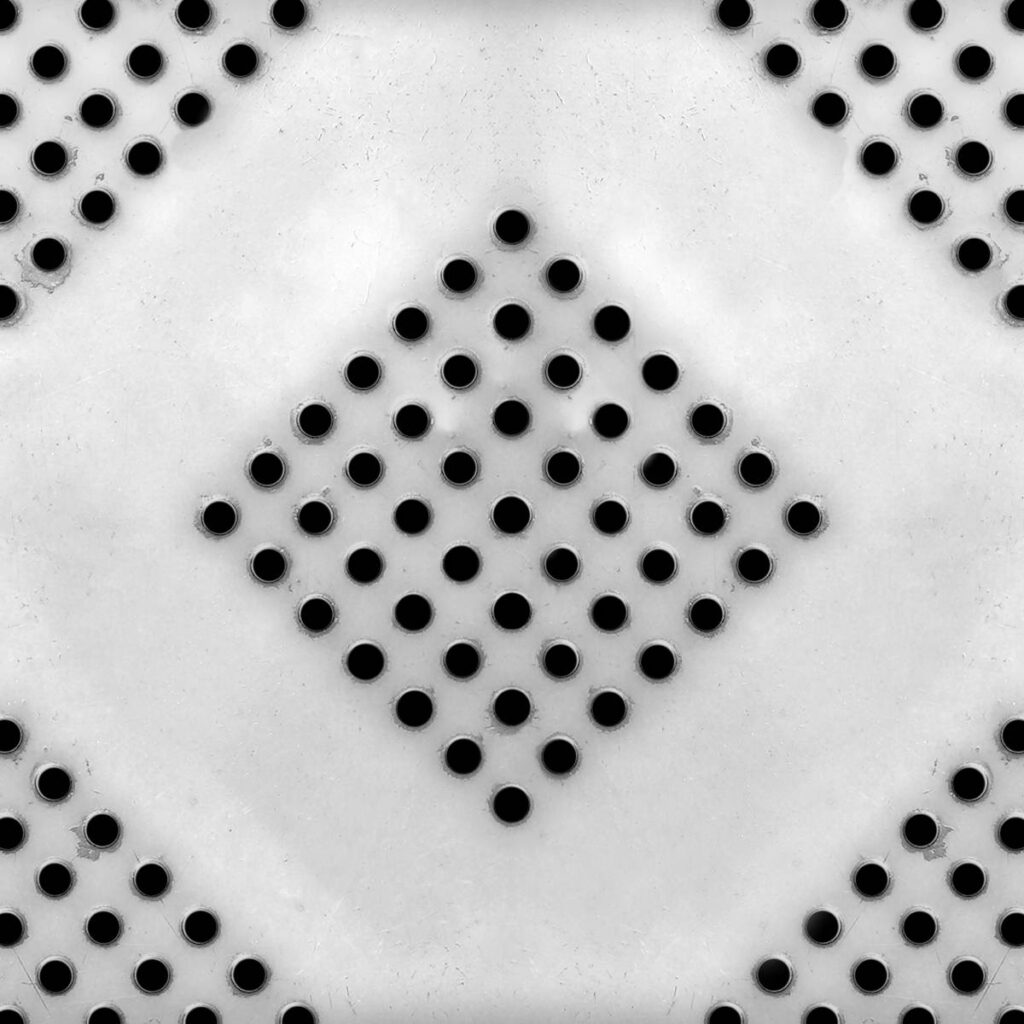

Some applications involve parts with a great many holes (for example: many thousands) that need to be checked. These parts can be made of different materials. We’ve worked on metal, carbon, ceramic and silicon parts like this. These parts are sometimes referred to as hole arrays or micro hole arrays.

These types of parts are used in different industries. Defense, semiconductor manufacturing, aviation and aerospace are a few industries that come to mind. Depending on the application, the holes can have different functions. Often, their presence has something to do with controlling a flow (of a gas, of particles, etc.). There could be different reasons for such flow control: It might be for cooling purposes, for uniformity of dispersion, etc. Gas Distribution Plates, used in semiconductor manufacturing and plasma reactors, are a typical example of these types of parts.

These parts are typically difficult to manufacture, and the holes have obviously been included in the part’s design for a reason, i.e. they have a role to play, typically a key one. So, most often, these parts need to be inspected in great detail to ensure that they will meet their requirements.

There are many different parts, across many different industries, that have a great many holes that need to be inspected

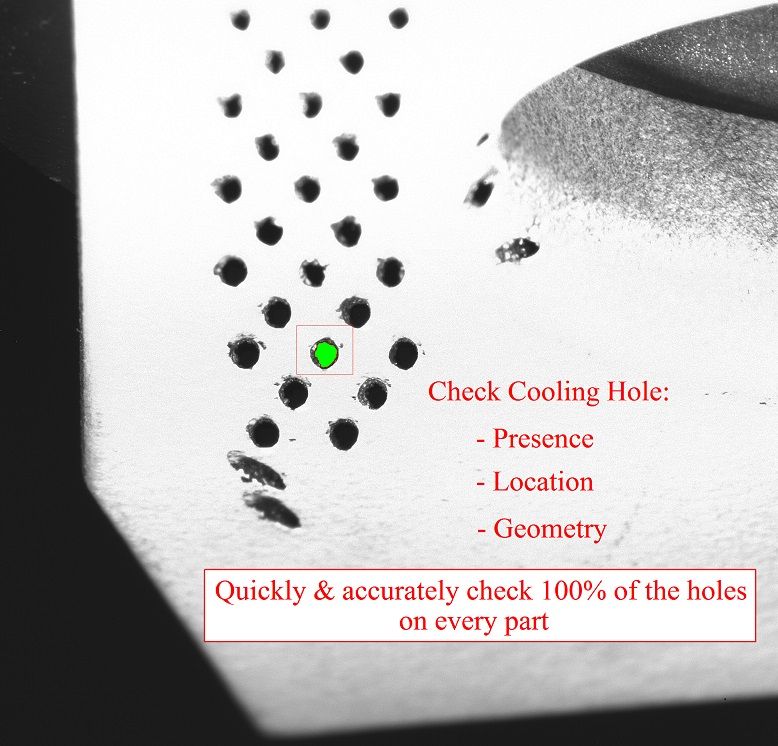

Typically, the inspection needs to ensure that all of the holes are present and that their location and geometry are correct. Note that, in some cases and depending on functional requirements, the holes might not necessarily be round. In fact, we’ve come across quite a wide range of different hole geometries in these types of projects.

Inspecting 100% of the holes can be both challenging and extremely time consuming. Most inspection systems, to obtain the needed level of detail, proceed hole-by-hole. If a part has 18,000 holes, for example, then even if every individual hole can be dealt with quickly, this approach still takes a tremendous amount of time to cover the entire part. We’ve heard of parts for which a complete inspection required full days and even multiple days.

The VisionGauge® Digital Optical Comparator is especially well suited to applications where parts have a very large number (e.g. many thousands) of closely grouped holes as it can analyze all of the holes visible in the entire field-of-view at once, very quickly and accurately. This approach involves absolutely no compromise on accuracy. All the while, throughput is increased tremendously.

Motion operations (i.e. physically moving the part or the camera) are typically the most time-consuming steps in inspection and measurement programs. In applications involving a large number of closely grouped holes, the optimized approach offered by VisionGauge® drastically reduces the number of motion operations needed since it doesn’t involve hole-by-hole movement but rather simply ensuring that the entire part has been scanned through field-of-view-by-field-of-view coverage.

Furthermore, VisionGauge® can analyze every individual hole in the field-of-view extremely quickly (e.g. milliseconds) as it captures a great many measurement points (typically: thousands) almost instantly.

Analyzing all of the holes in VisionGauge®’s large field-of-view in a single operation provides for an enormous speedup

Outline of the Inspection Approach:

In broad terms, this approach involves the following steps:

- Scanning the part, field-of-view by field-of-view

- At every field-of-view:

- Capturing an image

- Locating the holes

- Saving the hole data (i.e. X,Y location, & geometry)

- After the entire part has been scanned, comparing the measured hole data against the nominal hole data

So, in terms of programming, the program involves only a small number of instructions.

Scanning the Part

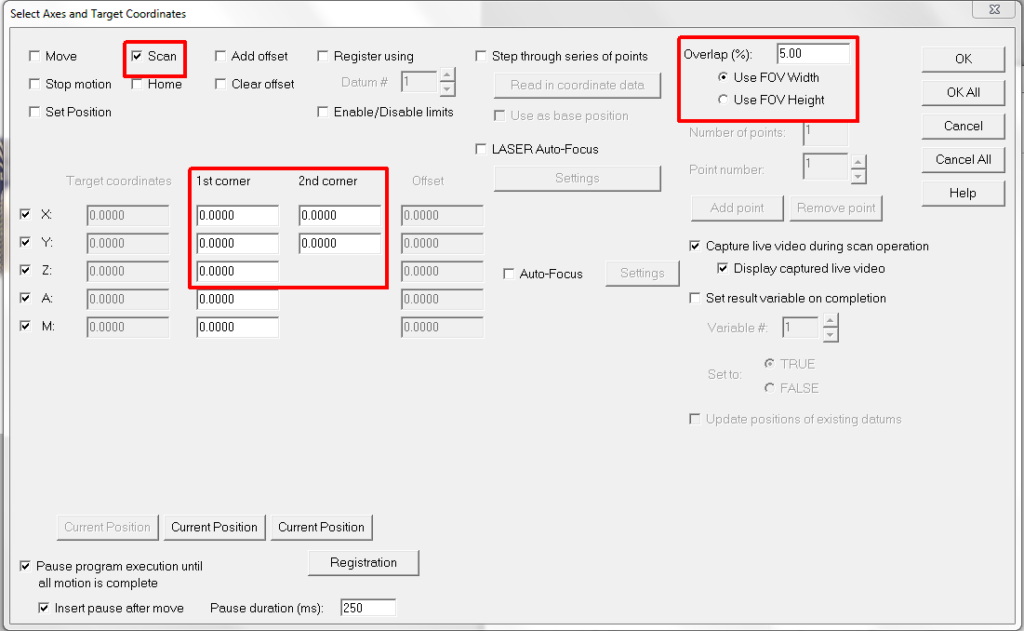

This is done using the software’s “Motion Control” tool, i.e:

As can be see above: we select the “Scan” mode, specify the 2 corners of the rectangular area to be scanned and also specify an overlap to ensure that every hole is completely visible in at least one field-of-view (i.e. we want to avoid that half the hole is visible in one field-of-view and that the other half is visible in the next field-of-view).

Capturing an Image

This is done using the software’s “Image Capture” tool.

Locating the holes and saving the hole data

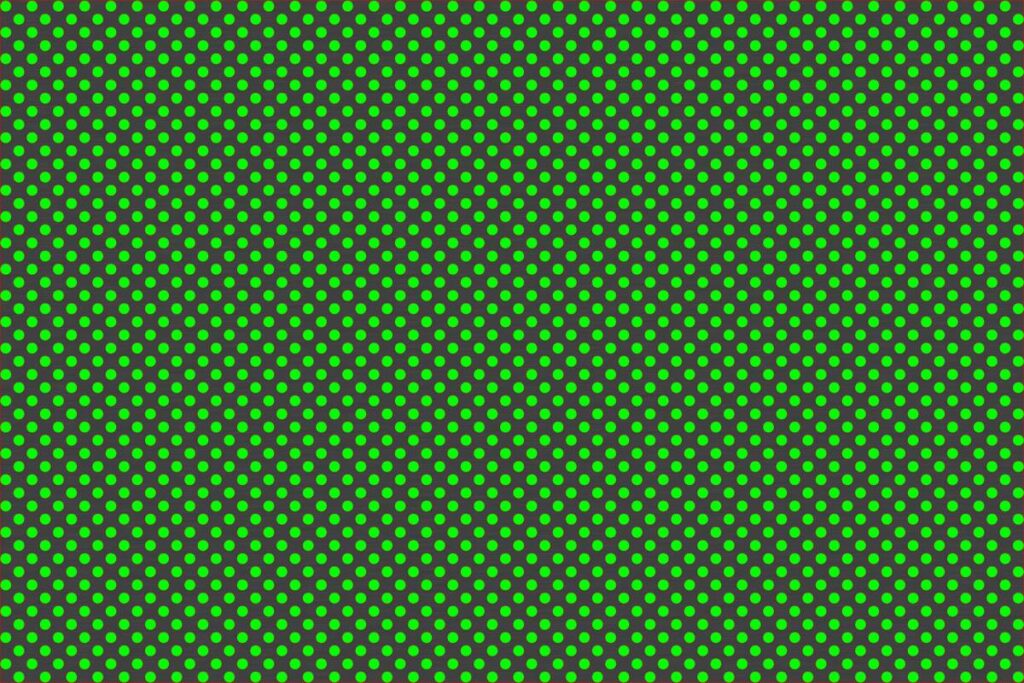

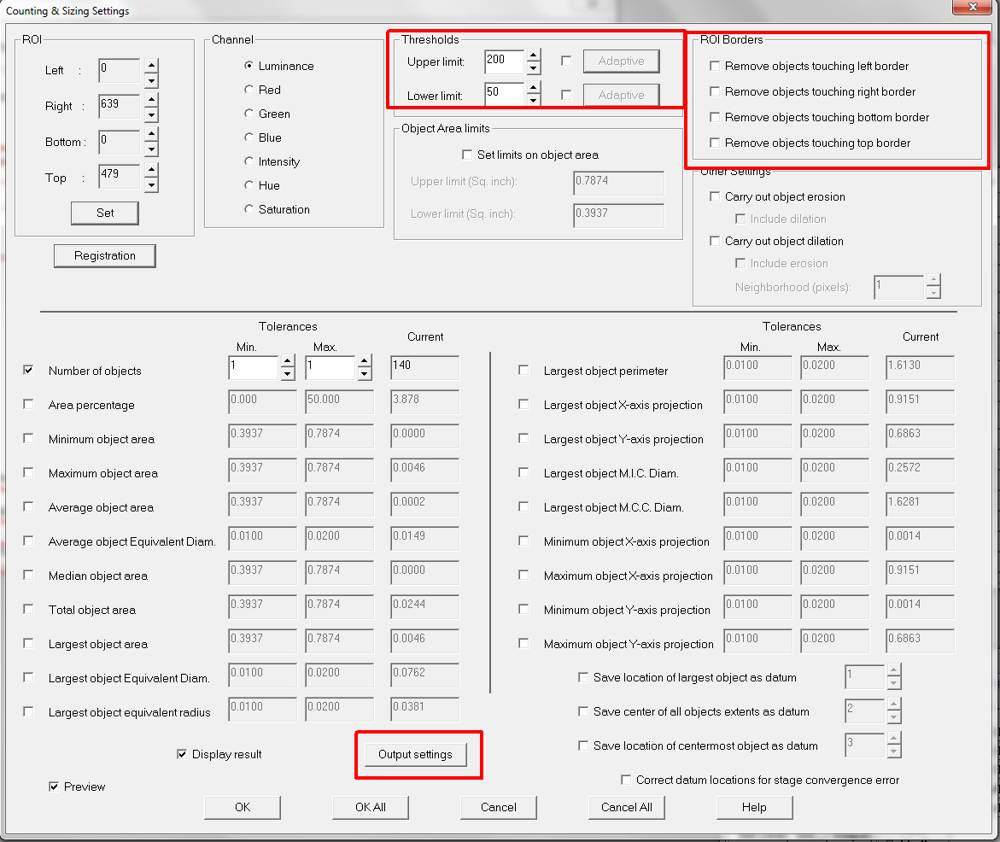

This is done using the software’s “Counting & Sizing” tool, i.e.:

This is an extremely general-purpose tool and you shouldn’t be taken aback when you see all of the parameters in the above window as – for this application – we don’t need most of them.

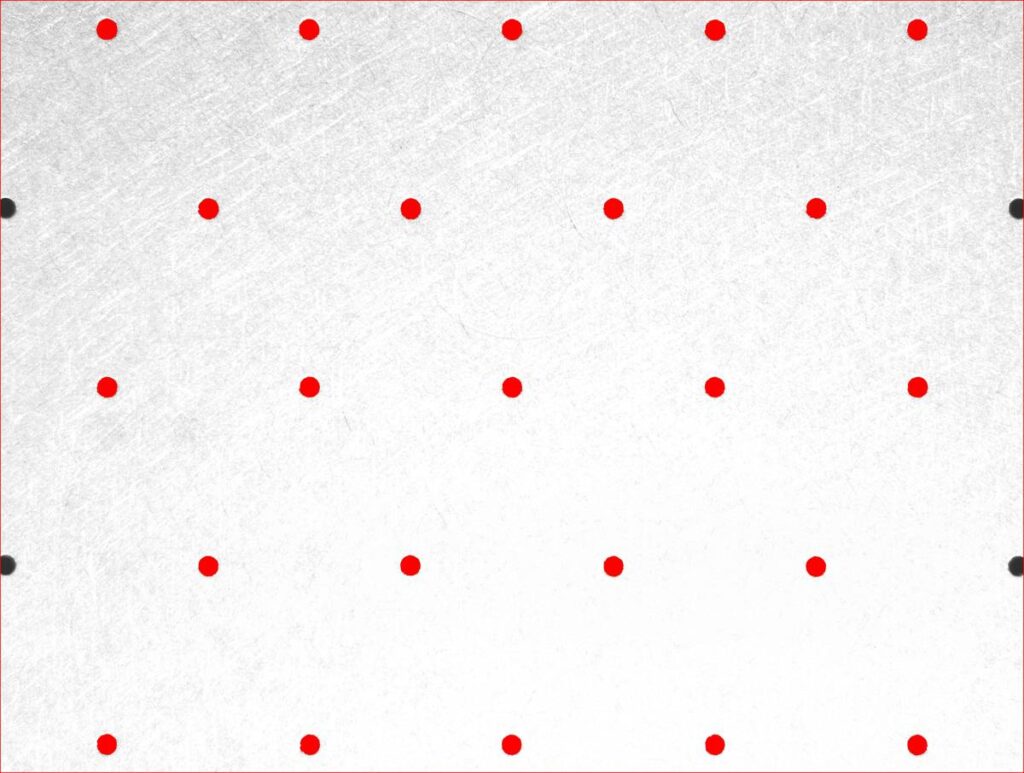

Here we simply set thresholds to separate the holes from the background (we can use adaptive thresholds that are extremely powerful…). We also tell the tool to disregard the holes touching the borders: With the scanning overlap, this is how we ensure that every hole is seen completely at least once.

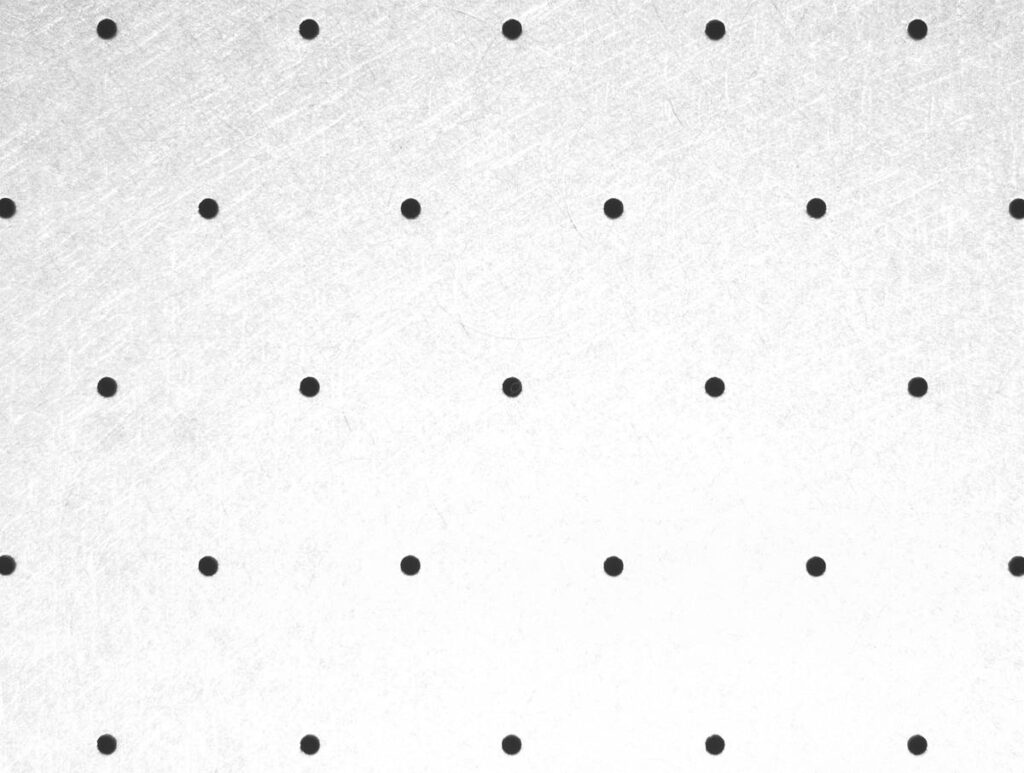

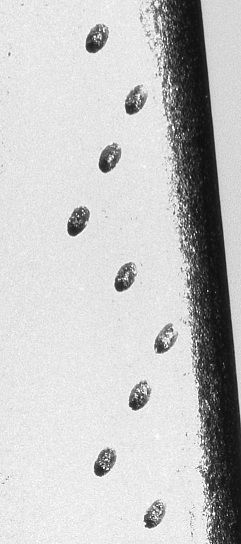

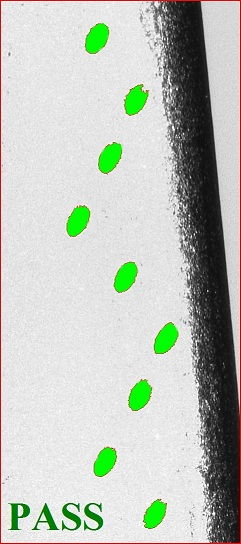

The images below, taken from a previous application of this type, illustrate this tool’s operation. Note that for reasons specific to this historical application, the images below are front illuminated (i.e. captured using reflected illumination). The holes thus appear dark and the part light. In most applications, we would use back (i.e. transmitted) illumination, which yields even more robust results.

Comparing the measured hole data against the nominal hole data

This is done using an external “Hole Checker” library that we have developed for exactly these types of applications. It reads-in a user-supplied text file with the nominal hole data (i.e. X,Y location and diameter, in the most basic case). It then compares the measured hole data to the nominal hole data. Note that if (because of the Image overlap) a hole was measured more than once, it is only the first of these measurements that is considered.

This “Hole Checker” tool produces a text file with 1 line per (nominal) hole, every line containing:

- The hole number (same as the input / nominal file)

- The hole nominal position (same as the input / nominal file)

- A PASS or FAIL indicating if the hole was found

- If the hole was found: the measured X & Y hole position

- If the hole was found: the measured hole diameter

Note that VisionGauge®’s “Map View” tool can also be used to provide a graphical layout of the results, as well as allow easy “operator review” of the results (i.e. click on a hole and the software brings it back in the middle of the field of view, so that the operator can revisit / review, etc.).

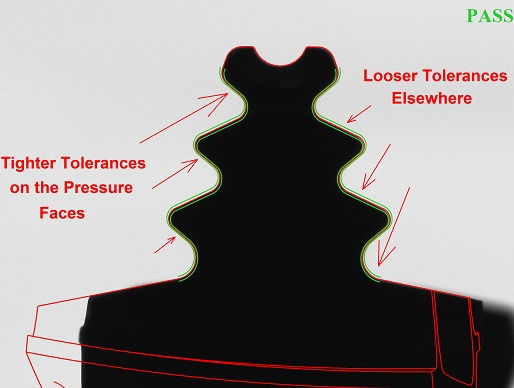

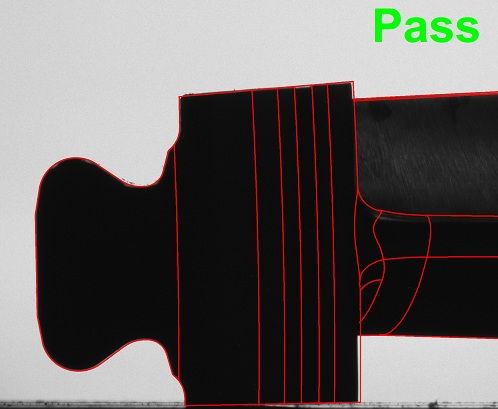

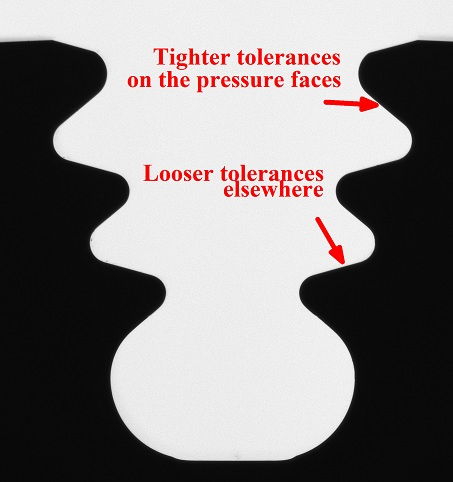

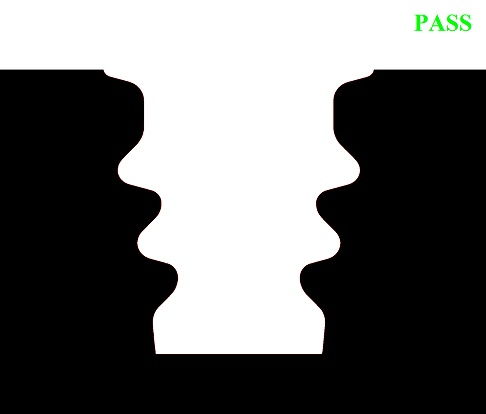

VisionGauge®’s extensive CAD-Comparison capabilities

Of course, VisionGauge® also has extensive CAD-Comparison capabilities (i.e. patented CAD Auto-Align™ & CAD Auto-PASS/FAIL™ tools). These can also be useful in this application, at the very least for “quick inspection & verification” purposes. For example: bring up the CAD file and quickly manually “move around the part” and generally asses the alignment of the holes to the CAD data. This can provide a quick confirmation / sanity-check as to whether or not “things look good” and glaring defects will “jump out” at the operator.

Summary

VisionGauge® offers powerful and unique tools that allow for highly optimized inspection and measurement of parts with a large number of holes, much faster than with traditional approaches. The results produced by VisionGauge® remain very accurate, to the instrument’s full resolution. Furthermore, these fast, accurate, and fully-automated inspections are very easy to setup with VisionGauge®.

Download a .pdf version of this VisionGauge® Digital Optical Comparator Application Note.

Read more about other applications VisionGauge® software and systems are being used to solve.