VisionGauge® Machine Vision Systems for MEMS and Manufactured Electronics Verification Applications

After schematics have been set and printed circuit boards (PCBs) have been produced, comes the final part of electronic manufacturing: assembly. Our VisionGauge® OnLine machine vision systems can help you perform the electronic assembly verification or PCB assembly inspection of your product after it has been finished.

Electronic Assembly Verification

Whether you have used surface mount, though-hole (thru-hole) or other technology, our software will help you accurately inspect every part of your assembled electronic device.

Our visual inspection systems include the advanced VisionGauge® OnLine toolset. All of VisionGauge® OnLine's image processing and analysis tools are thus available to automatically process the image before carrying out the assembly inspection.

There are numerous software tools employed by VisionGauge® OnLine to help facilitate your inspection, including:

- Optical Character Recognition & Verification (OCR / OCV) for serial numbers

- Blob Analysis for solder height detection

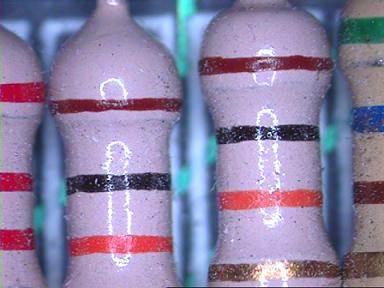

- Color Verification for devices and connections

- Presence / Absence Detection of components

- and many others...

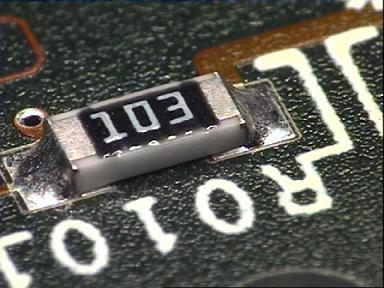

With our visual inspection software you will be able to accurately check every soldered tip in high magnification and high accuracy in three dimensions. You can also utilize VisionGauge® OnLine's OCR capabilities for serial number verification or model number recognition on your components. Or even use the color verification on ceramic resistors. There are countless possibilities for what you can accomplish with VisionGauge® OnLine.

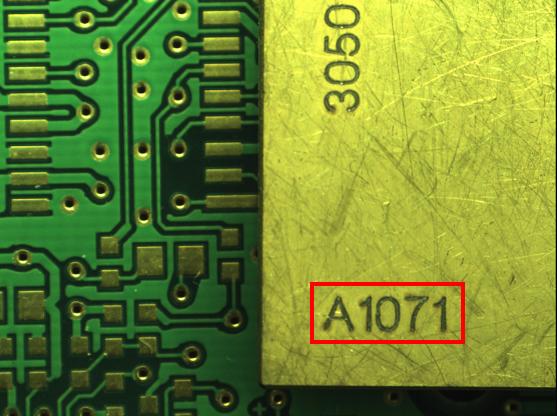

Small Component Serial Number Verification

VisionGauge® OnLine Optical Character Recognition Systems (OCR Systems) are able to reliably, automatically locate and read serial numbers on chips, PCB boards, or any other device that your application requires. This automated process captures the data in fractions of second so products can be tracked as they flow through the manufacturing process - maintaining a high-quality inspection standard. It can also verify that the text matches the expected character string, export & exchange these results, produce reports, trigger signals, etc.

VisionGauge® OnLine Optical Character Recognition Systems (OCR Systems) are able to reliably, automatically locate and read serial numbers on chips, PCB boards, or any other device that your application requires. This automated process captures the data in fractions of second so products can be tracked as they flow through the manufacturing process - maintaining a high-quality inspection standard. It can also verify that the text matches the expected character string, export & exchange these results, produce reports, trigger signals, etc.

These OCR Systems include the advanced VisionGauge® OnLine toolset to facilitate applications, such as microchip inspection. All of VisionGauge® OnLine's image processing and analysis tools are thus available to automatically "cleanup" the image before carrying out the character recognition operation. This can dramatically improve results in the cases where there is contamination, background noise, character spacing, contrast, etc.

With the VisionGauge® OnLine toolset you are also able to specify a region of interest on the image so only the desired area of the device is scanned. Even if the characters are not standard you can build-up your own custom character libraries by presenting "model" characters to VisionGauge® OnLine's OCR tool. Because of this, VisionGauge® OnLine is truly multi-lingual and can even be taught to recognize symbols. You can also adjust the threshold of recognition to the one that best fits your application.

With the VisionGauge® OnLine toolset you are also able to specify a region of interest on the image so only the desired area of the device is scanned. Even if the characters are not standard you can build-up your own custom character libraries by presenting "model" characters to VisionGauge® OnLine's OCR tool. Because of this, VisionGauge® OnLine is truly multi-lingual and can even be taught to recognize symbols. You can also adjust the threshold of recognition to the one that best fits your application.

Whether the devices are embedded on a board, or are still on a wafer, let VisionGauge® OnLine's powerful Optical Character Recognition algorithm help you achieve maximum results with the highest accuracy.

All the data obtained from inspections can be exported, exchanged, or put into a report. Contact us with your application, and we can create a VisionGauge® OnLine custom visual inspection system to meet your requirements.

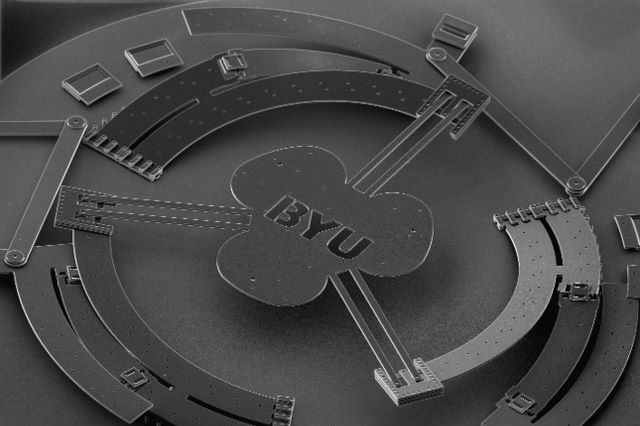

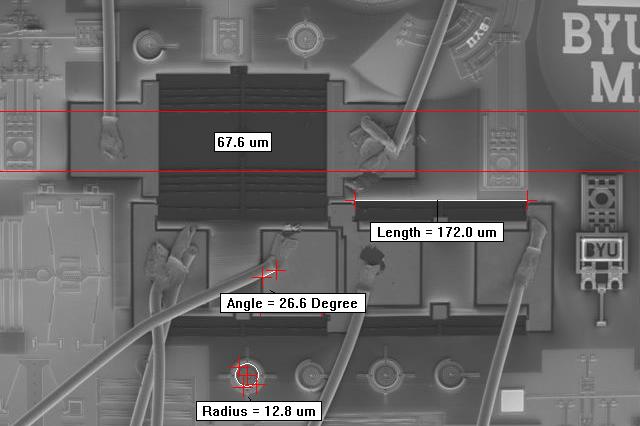

MEMS - Microelectromechanical Systems Inspection and Measurements

Microelectromechanical devices are a basic part of today’s technology. Used in such common places as inkjet printers, cellular phones, and mechanical accelerometers for automobile airbags, it is important for MEMS manufacturers to meet high production standards. VisionGauge® Online Automated Optical Inspections Systems (AOI Systems) can help you reach these standards through fully automated inspection and high-accuracy MEMS measurement.

Our AOI systems are able to be configured with high magnification optics and can provide measurement accuracy inside the micron spectrum - perfect for MEMs inspection. Additionally, the system is fully capable of repeatable motion in three dimensions which allows you to carry out measurements of objects that extend outside of the camera's Field-of-View.

These systems are fully programmable with the aid of our easy-to-use VisionGauge® Online machine vision software. There are numerous features in the software to facilitate your inspection, and with our custom inspection systems you can be sure our product will work for your applications.

With systems that can learn how to do the inspection for you, control input and output signals, and create customized reports, the VisionGauge® Online Automated Optical Inspections Systems (AOI Systems) are the perfect solution for Microelectromechanical Systems (MEMS) inspection and measurement applications.

Information is also available about more recent applications solved with our fleet of VisionGauge® Digital Optical Comparators.