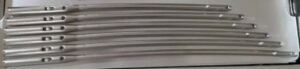

Intramedullary (IM) nails have long been used to treat fractures of long bones in the human body. An IM nail is a metal rod forced into the medullary cavity of a bone. VisionGauge® can perform measurements and quality inspections on these nails, fixation devices, and instruments that often accompany the nails.

Media Category: Applications

Images related to applications solved with the VisionGauge Digital Optical Comparator

Medical Intramedullary Nails Inspection and Measurement

The fractures in which IM nails are used are inherently unstable. So-called ‘locking’ nails, which are now the standard, use bolts on each end of the nail to fix it to the bony cortex, thus preventing collapse or rotation between the bone fragments.

IM Nail Measurements

The product variations of IM Nails combined with their complex geometries and anatomic shapes make the quality inspection of medical nails very challenging – a task VisionGauge® software and systems are able to meet.

IM Nail Inspection

IM Nails (Medical Intramedullary Nails) are widely used and provide an efficient, practical solution for treating a wide range of fractures (including shoulder, humerus, elbow, hip, femur & tibia…)

VisionGauge IM Nail Inspection Supports Various Lengths

Medical Intramedullary (IM) Nails are available in a very wide range of lengths, sizes and geometries – all of which are capable of measurement and inspection by VisionGauge®.

5-axis part positioning for accurate hole inspection

The 700 Series VisionGauge Digital Optical Comparator includes 5 axes of movement to properly position parts with complex geometries for optimal measurements.

Surgical instruments inspection

With the VisionGauge® Digital Optical Comparator, surgical instruments with cutting edges can be checked for sharpness and to ensure that there are no dull spots, chips, or dents.

Medical instruments inspection

The VisionGauge® Digital Optical Comparator offers a deep toolbox of specialized inspection and measurement modes to enable, for example, the accurate measurement of the location of grooves, markings and other types of unconventional features that specialized medical instruments can display.

Inspection of Manufactured Medical Tools

With the VisionGauge® Digital Optical Comparator, medical and surgical instruments with cutting edges such as scissors, rongeurs, chisels, curettes, etc., can be checked for sharpness and to ensure that there are no dull spots, chips, or dents.

Medical tools inspection

The VisionGauge® Digital Optical Comparator is a multi-purpose machine that has the flexibility to support the quality needs of the full range of products produced by medical manufacturers.