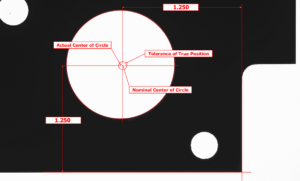

In this example, the hole’s nominal center point is defined precisely 1.250 inches vertically and horizontally from the corner of the part. The actual center of the hole is located, and the software automatically computes the True Position of the feature and reports a Pass/Fail result based on the diametric tolerance zone defined.

- Company

- Systems

- VisionGauge® Digital Optical Comparators

- 300 Series Field-of-View Systems

- 400 Series Desktop Inspection and Measurement Systems

- 500 Series Digital Optical Comparators

- 600 Series Compact Desktop System For Turned Parts

- 700 Series 5-Axis Inspection and Measurement Systems

- Disk Inspection and Measurement Systems

- Standalone Inspection & Measurement System

- Vision / Optical Measuring Systems

- Customized Inspection/Measurement Systems

- VisionGauge® Digital Optical Comparators

- Software

- Industries

- News

- Contact/Support