Extrusion Inspection and Measurement

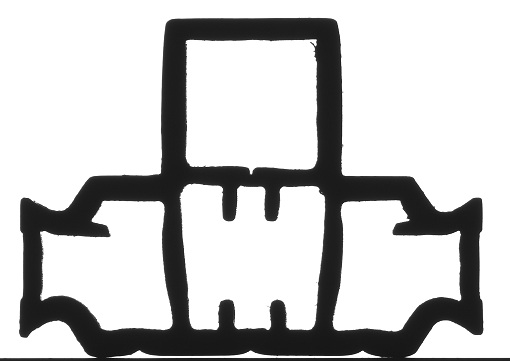

VisionGauge® Digital Optical Comparators are perfect for applications that require inspecting and measuring extrusions.

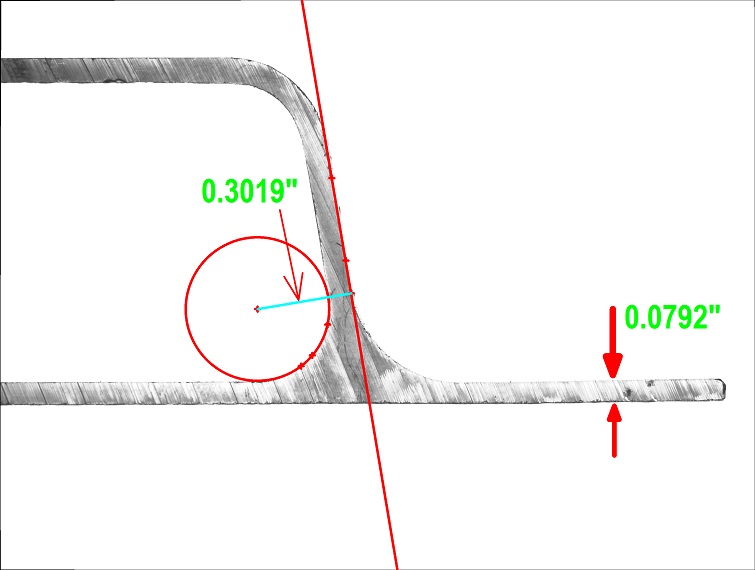

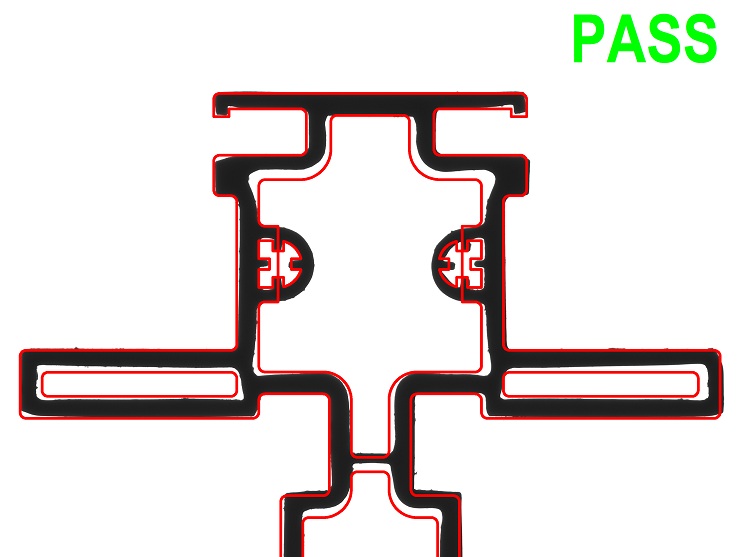

- The VisionGauge® Digital Optical Comparator automatically compares difficult-to-inspect extrusions against their CAD data (no more overlays!).

- VisionGauge®'s patented CAD Auto-Align™ feature automatically and accurately lines up the CAD to the part, along one or multiple datums or by performing an overall "best fit".

- Our patented CAD Auto-Pass/Fail™ tool automatically produces reliable Pass/Fail results - completely eliminating operator subjectivity.

- Automatically measure and display deviations from nominal and quickly identify out-of-tolerance areas.

- Variable and uniform tolerances are equally supported on the same parts: Tighter tolerances can be applied to some critical locations while looser tolerances are in effect in other places.

- There are absolutely no restrictions to part geometries, and the system works equally well on both fixtured and unfixtured parts.

- VisionGauge® Digital Optical Comparators can be used right on the shop floor to deliver highly-accurate and repeatable results without variation between operators.

- Multiple, flexible options are available for documenting and outputting measurement results, images, statistics, and additional data. Results can be reviewed following a part's inspection - or immediately and automatically exported to your SPC solution.

- Much faster and more accurate than traditional approaches!

- VisionGauge® Digital Optical Comparators are powerful and easy to operate: The system can run a complete, pre-programmed inspection routine and output results using just the barcode reader.

VisionGauge® systems possess a widely-applicable set of inspection and measurement tools and features that exceed expectations when it comes to the verifying the quality and characteristics of extrusions.

VisionGauge® Digital Optical Comparators are the extrusion industry's new standard for carrying out fast and accurate inspections. Get in touch with us with the specifics of your application to see how our systems can improve the quality of your verification process.

Download a .pdf version of this VisionGauge® Digital Optical Comparator Application Note. Also, read more about other inspection and measurement applications in various industries where our systems are regularly being employed.