VisionGauge�

Latest Improvements

VISIONx

INC. is always working

to improve VisionGauge�. The main improvements

and new features

that have been added to VisionGauge� (version

6.51) since

the previous major release (i.e. version 5.45) are the following:

-

Improved TIFF

image file format support.

-

It's now

possible to select multiple

images at once in the "Perfect focus" tool's window.

-

Improved

"Full Screen Live Video" support.

-

VisionGauge's�

"Counting

& Sizing" tool can now be told to ignore objects that touch the

image's

borders (we have included individual controls for the top, bottom, left

and right borders of the image).

-

Also in

VisionGauge's�

"Counting & Sizing" tool, we've added controls that allow the

user

to select the colors used to draw the objects (i.e. the color used to

draw

all of the objects in the sample as well the color used to draw

individually

selected objects).

-

In both the

Manual- and Motorized-Stage

Configuration of VisionGauge�, we've added

support for serial-port

devices, such as micrometer heads, height gauges, dial indicators,

etc...

VisionGauge� can now read in the stage position

for any

and all of the 3 axis through such serial-port data sources.

-

Users can now

set the file name as well

as the image file format (either Bitmap, JPEG, TIFF, or Targa) for the

one-key (or one-click) "Image Quick Save" tool. This is done through

the

"Settings | General preferences" menu command. These new settings are

also

saved in the "Setup" files.

-

We've added

some last enhancements that

have to do with stage control & automated measurements. With

this release,

the "fully-automated stage-based measurements" feature is now complete

& fully tested.

-

We've added

an "Options" menu to the

Calibration Toolbox that will allow you to increase the number of

pre-saved

calibrations up to 20.

-

We've added

the ability to rotate images

by an arbitrary (i.e. user-set) angle.

-

In the

motorized stage configuration

of VisionGauge�, we've corrected the software's

control

of very, very fine movements. These improvements have eliminated small

"jumps" and very fine "backlash" motions that could occur at very low

speeds

and that were only visible at extreme magnifications.

-

We've added a

new "Video Sequence Capture"

tool to VisionGauge�. You can use this new

feature to capture

full frame-rate (or slower, as set by the user) video to system memory.

Once captured to memory, the video can be played back, modified, saved

to

disk & retrieved later on, etc...

The

amount of video that can be captured

(i.e. duration) is only limited by system memory. Furthermore, with the

appropriate video acquisition hardware, VisionGauge�'s

new

"Video Sequence Capture" tool supports both analog and digital

cameras.

This

new feature is especially useful

for time-dependent processes (e.g. motion tracking, etc...)

-

It's now

possible for the user to manually

set the COM port initialization string when using serial port data

sources

for stage position feedback.

-

We've

improved VisionGauge's�

support for the PIXCI SV4 video acquisition board (for analog cameras):

higher live image refresh rate & better control of colors.

-

We've

improved VisionGauge's�

support for the PIXCI D video acquisition board (for digital cameras)

and

have added support for cameras that have a higher live image refresh

rate.

-

We've added a

new "Automated Angle"

measurement tool to VisionGauge�. With this

tool, the user

draws two "boxes" on the image and VisionGauge�

then finds

the strongest edge in each of these boxes and return the angle between

these two edges.

-

With the

"Marker-to-marker" measurement

tool, the "Center of circle" marker now uses the same number of

measurement

points as the "diameter" and "radius" measurement tools (i.e. more than

3, allowing the user to define a "best fit" circle).

-

We've added a

new "Zero position" marker

to VisionGauge's� "Marker-to-marker" measurement

tool. This

"Zero position" marker is used for stage-based measurements and allows

you to measure the distance between any other type of marker (e.g.

"Center

of circle", "Center of arbitrary 4-vertex feature", etc...) and the

stage's

zero position. VisionGauge's� new "Zero

Position" marker

is especially useful when you need to measure the distance between one

(common) reference position many different features. In this case, if

you

set the stage "zero" to the common reference position you'll be able to

carry out all of your measurements very quickly because you won't have

to re-define the reference position for every measurement.

-

We've added a

new "Orthogonal to line"

marker to VisionGauge's� "Marker-to-marker"

measurement

tool. This "Orthogonal to line" marker allows you to measure the

orthogonal

(i.e. shortest) distance between any other type of marker (e.g. "Center

of circle", "Center of arbitrary 4-vertex feature", etc...) and a

line.

-

In the

Motorized Stage Configuration

of VisionGauge�, we've linked the jog velocities

& accelerations

to the system's optical magnification. The jog velocities and

accelerations

for the three jog modes (i.e. slow, medium and fast) are those used

when

the operator moves the stage with either the external or on-screen

joystick.

Here's how this works: VisionGauge� now saves

the jog velocities

and accelerations to the calibration toolbox, along with the

calibration

coefficients. This way, when the user presses one of the buttons in the

Calibration Toolbox, the corresponding jog velocities and accelerations

are loaded into VisionGauge�, along with the

corresponding

calibration coefficients. This is very useful, as it is often desirable

to vary the jog velocities and accelerations depending on the optical

magnification

(i.e. we generally want slower movements at higher magnifications, and

faster movements at lower magnifications).

-

In

VisionGauge's� Area

Measurement tool, in addition to the existing "Straight line" drawing

capabilities,

we've added "Free hand" drawing capabilities.

-

We've added

"Measurement Tolerances"

to VisionGauge�. You can enable this feature and

set the

upper and lower measurement limits through the "Settings | Measurement

mode" menu option. "Measurement Tolerances" are especially useful when

carrying out fully automated stage-based measurements using the

Motorized

Stage Configuration of VisionGauge�. In this

case, you can

tell VisionGauge� to terminate (or not) the

automated measurement

program upon encountering an out-of-tolerance measured value by

checking

the appropriate box in the "Settings | Motion Control" menu option of

VisionGauge's�

Motion Toolbox. Please note that, when carrying out fully automated

stage-based

measurements with VisionGauge�, it is possible

to set different

upper and lower limits for each individual measurement, in exactly the

same way that it possible to set different modes for each individual

measurement.

It is also possible to turn the "Measurement Tolerances" feature On or

Off for each individual measurement. So, for example, it is simple to

create

an automated measurement program comprised of three measurement: the

first

a simple "point to point" measurement that should not be compared

against

any limits, the second a "marker to marker" measurement that must be

within

certain limits, and the third still another type of measurement that

must

be within a different set of lower and upper limits...

-

VisionGauge�

now supports

a new PCI bus quad card. In the Manual- and Motorized-Stage

Configurations

of VisionGauge�, a quad card is used to

accurately read-in

the stage's position. The existing ISA bus quad cards will continue to

be available. However, because PC manufacturers are gradually

eliminating

ISA slots from their computers, compatibility with this new PCI bus

quad

card will allow VisionGauge� to remain current

with the

evolution of the PC architecture.

-

We've enhanced VisionGauge's�

JPEG image file support, by updating to the new release of the Intel

JPEG

Library (i.e. version 1.5, released on Friday October 27th 2000).

-

We've improved the auto-focus

(added

an "emergency stop", etc...) and we've also carried out some minor

improvements

having to do with stage motion control.

-

We've further enhanced our

support of

JPEG image files.

-

We've added the ability to

"Zoom out"

when working with very large images (i.e. larger than the available

viewing

area. This allows you to "see" - and work on - the entire image all at

once, without having to actually reduce it's resolution. When you press

"Zoom out" a second time, the image is once again displayed in full

resolution

(with the usual "slider bars" for scrolling...).

-

We've added support in

VisionGauge�

for EPIX's� modified drivers for their PIXCI D�

& PIXCI SV4� video acquisition boards.

-

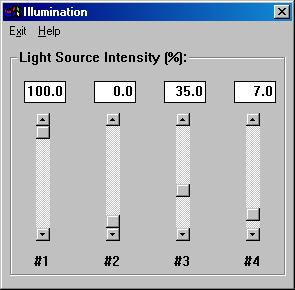

VisionGauge�

now supports

"Computer-Controlled Illumination". This means that VisionGauge�

will now let you control up to 4 different light sources.

The "Computer-Controlled

Illumination"

menu command is located in VisionGauge's�

"Command" sub-menu.

You can also use the "Control-U" hotkey combination to activate it. The

interface through which you control the light sources is very

intuitive.

You can either use the slider-bars to raise & lower the light

intensity

coming from each source or you can directly type in the relative

intensity

that you want.

Furthermore, the intensity of

each

source is saved in the "setup" files, so that when you recall a "setup"

from disk, the intensity of all of the light sources is automatically

re-set

to the appropriate values saved to disk.

VisionGauge's�

new

"Computer-Controlled Illumination" feature is very useful to speedup

operations

(i.e. much faster than having to reach for light source knobs) and also

leads to much more repeatable light intensities, which results in more

repeatable & accurate measurements.

- We've

added the "File | Open..." and "File

| Save As..." menu commands to VisionGauge's�

Calibration

Toolbox. You can use these new commands to save to disk the entire

contents

of the Calibration Toolbox & reload it later on. This is

especially

useful if different users of VisionGauge� want

to setup

the Calibration Toolbox differently. It is also another way to have

rapid

access to more calibrations than the toolbox's current maximum of 20

pre-saved

values...

-

We've added four "image

stitching" tools

(i.e. "left", "right", "above" and "below") for creating mosaics by

putting

images side-by-side. You can find these new tools in VisionGauge's�

"Edit" sub-menu.

-

We've enhanced VisionGauge's�

"Computer-Controlled Illumination" feature: when you change the

illumination,

Live Video is turned On automatically, so that you may directly see the

results on-screen.

-

We've added a new "Combine"

feature

to VisionGauge's� "Video Sequence Capture" tool.

You can

use this new "Combine" feature to transform the video sequence - made

up

of many component images - into one (large) image. The "Combine"

feature

also allows you to a) specify an image offset (to get rid of any

overlap

that may exist between side-by-side images) and b) resize the resulting

"combined" image.

You'll find this new "Combine:"

feature

especially useful when you're capturing video of a moving object or

scene.

In this case, the "Combine" feature allows you transform the video

sequence's

many component images into one (large) image of the entire object (or -

in the case of a moving scene - the "Combine" feature lets you build a

single "panorama" image from the video sequence).

- We've

improved VisionGauge's�

support of very(!) large images (i.e. enhanced memory management and

image

display routines as well as improved image manipulation tools).

-

We've enhanced VisionGauge's�

to allow field-of-view measurements during "Live Video" acquisition. To

enable this feature, check the "Allow Measurements during Live Video"

checkbox

in VisionGauge's� "Settings | General

Preferences" menu

option. Please note that - like all of the other settings and state

variables

- this checkbox's state is saved in VisionGauge's�

"Settings"

files. It is important to note, however, that edge-detection is not

available

for such "Live Video" field-of-view measurements (e.g. edge-detection

is

not desirable because of vibration, etc...).

-

We've added new "freehand"

drawing tools

in both the "Live Image Overlay Builder" and the "Annotation Toolbox".

To add a "freehand" overlay or annotation, simply select this new tool

from the appropriate menu, click once on the image to activate the

"freehand

drawing" tool, move the mouse to draw in "freehand" mode and click on

the

image a second time to turn the "freehand drawing" tool off. This new

tool

is very useful for outlining unusual shapes or boundaries, for example.

-

We've added a new "Pathline"

measurement

tool in VisionGauge�. This new "Pathline"

measurement tool

can be used both for field-of-view measurements as well as for

stage-based

measurements beyond the optical field-of-view (and this with both

manual

and motorized stages). A typical example of an application for this

tool

is to obtain a precise measurement of the perimeter of an

irregular-shaped

object. Finally, it should be noted that this new "Pathline"

measurement

tool is fully compatible with VisionGauge's�

powerful edge-tracker

(for automatic edge-detection).

-

We've added Full-Screen Live

Video support

to VisionGauge� when using the Integral

Technologies FlashBus

MV family of video acquisition boards.

-

We've added multi-camera

support to

VisionGauge� when using the Integral

Technologies FlashBus

MV family of video acquisition boards.

-

With certain video display

boards, 640

x 480 images would be slightly "taller" than VisionGauge's�

display area when using a 800 x 600 "desktop" display resolution and

would

thus not be displayed entirely (i.e. a vertical slider bar would be

available

to scroll the image either up or down). We have resized the status box,

at the bottom of the main VisionGauge� window,

so as to

allow the entire image to fit "all at once" under these conditions.

-

In the Motorized-Stage

Configuration

of VisionGauge�, we've added the ability to

read-in "generic"

ASCII data files containing raw coordinate data. This data can then be

used to create full motion programs in VisionGauge�.

CAD

programs, as well programmable production machines (for example: CNC

drills

& routers, etc...) are able to output such raw ASCII coordinate

data,

making this a very generic and robust way to import existing part data

into VisionGauge�. Finally, please note that

this raw coordinate

data must be expressed in the same units as VisionGauge�

current measurement units (i.e. if VisionGauge's�

current

measurement units are microns, then this data must also be in microns,

etc...).

-

We've added the ability to add

"comments"

within a Motion Program. These are user-defined text messages that are

displayed at certain user-specified positions within the motion

program.

For example, you might want the message "Turn back-light on" or "Make

sure

that there is no remaining solder mask" displayed when the program

reaches

point #25...

-

We've added a "skew function"

in both

stage-based configurations of VisionGauge� (i.e.

the Manual-Stage

Configuration and the Motorized-Stage Configuration of VisionGauge�).

This feature allows you to adjust - or "correct" - both motion programs

& measurements for a part's skew. Another way to say this is

that VisionGauge's�

"skew function" allows you to create true XY programs & get

true XY

measurements even if the part is not perfectly "square" with the stage.

The skew function automatically "rotates the part" in memory so as to

make

it mathematically "square" with the stage.

It is very easy to create a

"skew

corrected" program using VisionGauge's� "teach"

mode. Simply

proceed as follows:

1. Start by setting the part's

"zero"

position;

2. Then, tell

VisionGauge�

how the part is skewed relative to the stage. You do this through the

"Command

| Skew Part..." menu command, either in the Motion Toolbox or the DRO

window.

VisionGauge� will then ask you to pick two

points along

the part's X-axis.

Then, when you

later recall this

part program and wish to measure a part that is skewed differently from

the first part, simply repeat the same 2 steps...

To disable skew-correction,

simply

press the "Un-Skew" button in either the Motion Toolbox or the DRO

window.

Please note that it is good

practice

to try to keep skew corrections as small as possible (i.e. you should

attempt

to keep parts as "square" with the stage as possible). If the parts are

skewed very differently from one to the next, then stage calibration

(either

LEC or NLEC) becomes critical.

-

We've added a new "Offset" tool

that

you can use to create & edit motion programs in the

Motorized-Stage

Configuration of VisionGauge�. This new "Offset"

feature

allows you to take the definition of a device (including all of the

related

motion program data) and make multiple copies of it at specific (X, Y,

Z) offsets.

As an example, let's consider a

sample with 4 rows of 5 devices so that, in total, there are 20

identical

devices. In this example, you would use VisionGauge's�

"teach"

mode to define a single device (including changes in illumination,

measurement

mode, etc...), and then make 5 copies of this device definition at

specified

(X, Y, Z) offsets, so as to obtain a complete row. In a second step,

you

would use the "Offset" tool to make 4 copies of this row, at the

appropriate

(X, Y, Z) offset.

It is now possible to change

the

"Live Image Overlay" line width in VisionGauge�.

This is

the width of lines used for both standard overlay objects such as

"Crosshair"

and "Bulls-eye" overlay objects, as well as the line width in

VisionGauge's�

"Overlay Builder".

-

We've added Non-Linear Error

Correction

(i.e. NLEC) in both stage-based configurations of VisionGauge�

(i.e. the Manual-Stage Configuration and the Motorized-Stage

Configuration

of VisionGauge�). NLEC allows you to correct for

system

inaccuracies that cannot be properly accounted for using simple linear

error correction (i.e. LEC).

To carry out NLEC, simply

select

the "Motion | NLEC..." menu command. You will then be asked to mark the

stage

zero position as well as the zero position of your calibration grid.

After

this, you will be asked to enter calibration points. Please note that

VisionGauge's�

NLEC requires - as a minimum - 10 calibration points. Also, VisionGauge�

has no special requirements as to where the calibration points are

located.

It is always a good idea, however, to attempt to space-out the

calibration

points somewhat uniformly. And it is certainly not a good idea to have

any area of the stage severely under-covered by calibration points.

Also,

if you see that your system has a noticeable and precisely located

point

inaccuracy, it is probably a good idea to increase the density of

calibration

points around this area.

Once you've completed NLEC,

VisionGauge�

will automatically save to disk all of the necessary calibration data

so

that it will always be applied until you either erase it from disk or

carry-out

a new NLEC calibration. The NLEC calibration data is saved in the file

named "VisionGauge.nlec". This file is located in the main VisionGauge�

sub-directory.

Once you've carried out NLEC,

it

is very important that you remember to set the stage zero position

every

time you startup VisionGauge�, before carrying

out any measurements.

You do this by giving the "Command | NLEC: Set Stage Zero" menu command

in either the Motion Toolbox or the DRO window.

- We've

added a new type of "marker" to

VisionGauge's� "marker-to-marker" measurement tool: the

"centro�d

of a thresholded object" (sometimes, a thresholded object is also

referred-to

simply as a "blob"). This new type of marker is available for both

field-of-view

and stage-based measurements (either manual or fully-automated). In

both

cases, this is an extremely fast "one-point" measurement tool that is

very

simple to use: simply click on the object of interest and let

VisionGauge�

find it's centro�d.

So - for example - you can use

this

tool to measure the distance between the center of a "blob" and any

other

marker, such as the perpendicular distance to a line, or the center of

another blob, or a line midpoint or a simple point marker... Finally,

please

note that you can set different lower & upper thresholds for

markers

#1 and #2.

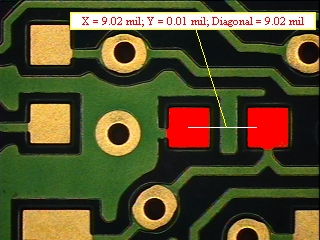

The following image shows a

simple example of a "marker-to-marker" measurement

where both markers are the "centro�d of a thresholded object" (the

thresholded object, in this case, is simply a PCB interconnect pad).

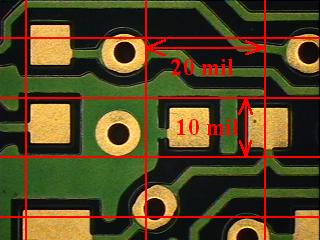

- We've added a new "grid" tool in both VisionGauge's�

"Live Image

Overlay

Builder" and Annotation Toolbox. When you access this new "grid" tool

through

VisionGauge's� "Live Image Overlay Builder", it allows you to put a

calibrated grid "over" the live video image, whereas when you access it

through VisionGauge's� Annotation Toolbox, it allows you to superimpose

a calibrated grid over a "frozen" image. The grid increment is

user-specified

and can be different along the horizontal & vertical axis (as

illustrated

in the image below). Finally, please note that the thickness, color

&

style of the grid's lines is entirely user-selectable.

- We've added three new measurement tools in

VisionGauge� to measure:

1. the area

2. the equivalent diameter, and

3. the radius

of a thresholded object

(sometimes, a thresholded object is also referred-to

simply as a "blob"). These new measurement tools are available for both

field-of-view and stage-based measurements (either manual or

fully-automated).

These are extremely fast "one-point" measurement tools that are very

simple

to use: simply click on the objet of interest and let VisionGauge�

carry out the measurement.

- We've

added the capability for programmable

illumination to the Motorized-Stage Configuration of VisionGauge�.

You should note that all of the editions of VisionGauge� have the

capability

for computer-controlled illumination, but fully-programmable

illumination

is only available in the Motorized-Stage Configuration of VisionGauge�

as it is only this edition that is capable of fully-automated

measurements.

This

fully-programmable illumination

feature lets you setup different illumination configurations at each

measurement

point. VisionGauge� can control up to 4 light sources. All of the

information

about the illumination configuration at each measurement point is also

saved in the motion program file, along with the rest of the coordinate

data & measurement mode settings so that the illumination

settings

are an integral component in the "part program".

It is also

worth noting that the

programmable illumination is extremely simple to setup. Another

noteworthy

feature is that VisionGauge� changes the illumination to the "next"

settings as soon as is possible (i.e. even before the stage starts

moving

to go to the next measurement point). This give the light sources as

much

time as possible to stabilize before VisionGauge� starts

carrying

out its measurements.

VisionGauge's� new programmable

illumination feature is another useful tool that will allow you to

solve

difficult applications and increase measurement repeatability!

- We've

enhanced VisionGauge's� automated

line width measurement tools tools to make them compatible withfully

automated

stage-based measurements. To do this, we've added the ability to

associate

a "Region of interest" (ROI) with each measurement point in a motion

program.

VisionGauge's� automated "Orthogonal line width" and "Arbitrary line

width" measurement tools can then be applied within this ROI.

-

We've added two new measurement

tools

to VisionGauge's� already extensive measurement toolset. These new

measurement tools will let you measure the maximum X & Y

dimensions

of a thresholded object (sometimes, a thresholded object is also

referred-to

simply as a "blob"). These new measurement tools are available for both

field-of-view and stage-based measurements (either manual or

fully-automated).

They are extremely fast "one-point" measurement tools that are very

simple

to use: simply click on the objet of interest and let VisionGauge�

carry out the measurement.

-

We've added a new "Centered

crosshair"

tool in both VisionGauge's� "Live Image Overlay Builder" and

"Annotation

Toolbox". When you access this new tool through VisionGauge's� "Live

Image Overlay Builder", it allows you to put a centered crosshair

"over"

the live video image, whereas when you access it through VisionGauge's�

"Annotation Toolbox", it allows you to superimpose a centered crosshair

over a "frozen" image.

-

We've added a "JPEG Image

Quality" setting

to the "Settings | General Preferences" window. Acceptable values for

this

setting range from 0 to 100. A higher value produces less compression

and

thus a better quality image, but of course a larger file size. Like all

other state variables in VisionGauge�, this parameter is saved in the

"setup" files.

-

We've added the ability to turn

the

Auto-focus & Edge Detection (i.e. VisionGauge's� "Snap Mode")

both

On & Off from within a Motion Program. The ability to do this

can come

in handy in some of the more challenging applications. These

enhancements

make our Fully-Automated 3D Measurement Systems even more

powerful

& just as easy to use!

-

We've enhanced VisionGauge's�

support

of the Integral Technologies FlashBus MV� video acquisition board.

For instance, we've added more on-line board-specific installation

instructions

that will help when setting up the board & with troubleshooting.

-

We've enhanced VisionGauge's�

Fully

Automated High Accuracy Volume Measurement Tool. Specifically, here's

what

has been done:

We've added more flexibility to

the

controls that allow you to define areas that you want VisionGauge�

to ignore for the volume calculations. You can also set &

change this

"disregarded" area's color in all of the different modes that are

available

to view the results (i.e. blended image, height map & 3D

projection).

We've also improved the

different

tools available for viewing the results and made them more

"interactive"

(e.g. the displayed "preview image" is changed as soon as you change

the

parameters).

We've also given the user more

control

over how the results are displayed (e.g. you can now change the mesh's

line width in the 3D projection mode, etc...)

Finally, we've also added some

extra

controls over the algorithms that actually do the volume computations.

We added a "limiter" control that you can use to tell VisionGauge�

to automatically disregard areas where the edges are very weak

(relative

to all of the other edges across the entire image). This new "limiting"

control can be very useful when you're working on a sample on which the

feature of interest is visible & clear, but where the

background is

very "flat" (i.e. there are absolutely no edges or visible features).

In

this type of a situation, the new limiting control is very useful to

tell

VisionGauge� that it shouldn't attempt to "find edges where there are

none".

- We've added a new "Calibrated Circle" tool in

VisionGauge's� "Live

Image Overlay Builder". This new tool allows you to precisely position

a circle of a user-specified diameter, at a user-specified (x, y)

distance

from the center of the field-of-view.

We've added a new "Calibrated Angle" tool in VisionGauge's�

"Live Image Overlay Builder". This new tool allows you to draw two

lines

that meet at the center of the field of view and that form a

user-specified

angle. You can also specify in which quadrant of the image this angle

is

to be drawn (i.e. Top-Left, Top-Right, Bottom-Left or

Bottom-Right).

Follow this link to see the previous

list of enhancements (i.e. those that are slightly less

recent)

|