Proper aerospace part inspection is crucial for ensuring quality manufacturing. The traditional manual methods for measuring geometric compliance are inefficient and slow. Explore how the VisionGauge® 700 Series and automatic inspection of aerospace components can reduce production bottlenecks and quality escapes.

The Critical Role of Precision in Aerospace Manufacturing

There is no room for error in aerospace manufacturing. AS9100 standards and zero-defect expectations from aircraft engine OEM supply chains require your parts to be within tolerance to maximize aircraft safety and efficiency.

Manufacturers are under immense pressure to build faster due to record backlogs of aircraft orders. At the end of 2025, there was a backlog of 17,000 aircraft, equivalent to almost 12 years of the current production capacity.

The production bottleneck is largely due to the use of traditional inspection methods for aerospace parts. For example, coordinate measuring machines (CMMs) are slow and often require laboratory conditions for accurate results. Manual checks are inefficient because they’re entirely subjective and vary from operator to operator.

The solution to speeding up the inspection process and increasing throughput is to improve the inspection technology. The VisionGauge® 700 Series Digital Optical Comparator automates inspections, accelerating the process.

Introducing the 700 Series Digital Optical Comparator

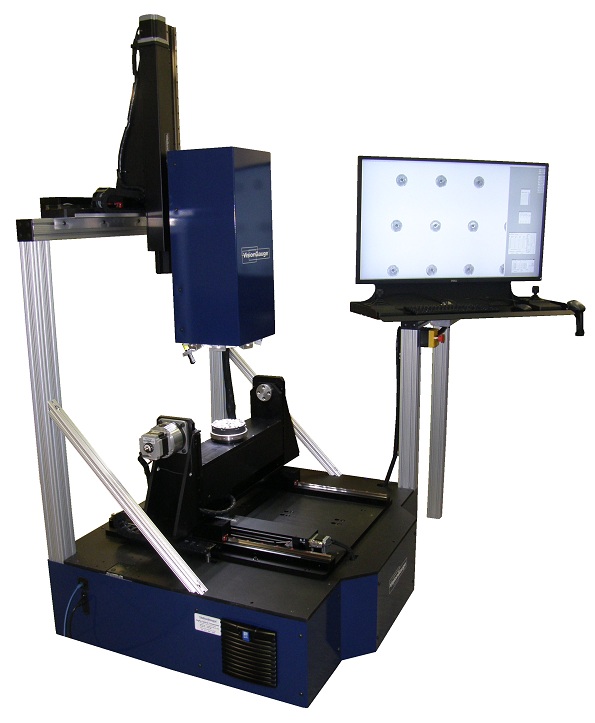

The VisionGauge® 700 Series Digital Optical Comparator is a five-axis inspection and measurement system. This non-contact system can overlay a CAD file directly onto the video image for an instant, data-driven Pass/Fail or Go/No-Go result. You can use this system to inspect round and square-shaped holes or slots on your aerospace parts, including fuel injector ports, fir tree roots, and parts with complex geometries. It can even manage burrs and splatter.

Unlike CMMs, the Digital Optical Comparator is a rugged machine that can sit right next to CNC machines directly on the shop floor for instant feedback on parts. It reduces the bottleneck of transporting parts for inspection. It also provides operators or controllers with real-time feedback to correct machining processes more quickly, minimizing rejections.

Why Aerospace Parts Need 5-Axis Inspection

Five axes of stage movement allows the VisionGauge® 700 Series Digital Optical Comparator to inspect complex shapes like turbine blades, vanes, and nozzles in a single setup. Rather than having to stop the machine, remove the part, flip it over, and clamp it down, the machine moves the part on five axes. That includes X, Y, and Z axes, as well as rotation and tilt. This ability reduces cycle times and minimizes human error, especially when inspecting large volumes of parts.

Aircraft part inspection needs a five-axis system to solve the line-of-sight challenge. Systems with three-axis inspection capabilities present some holes as distorted ovals — many cooling holes and fuel ports are drilled at acute angles relative to the surface. The VisionGauge® 700 Series Digital Optical Comparator can move the part to align the camera over the hole automatically, providing efficient, accurate results.

With an extended depth of field, our digital optical comparator keeps the entire curved part in focus at once. It solves the problem of accurate edge detection on rounded parts, improving accuracy.

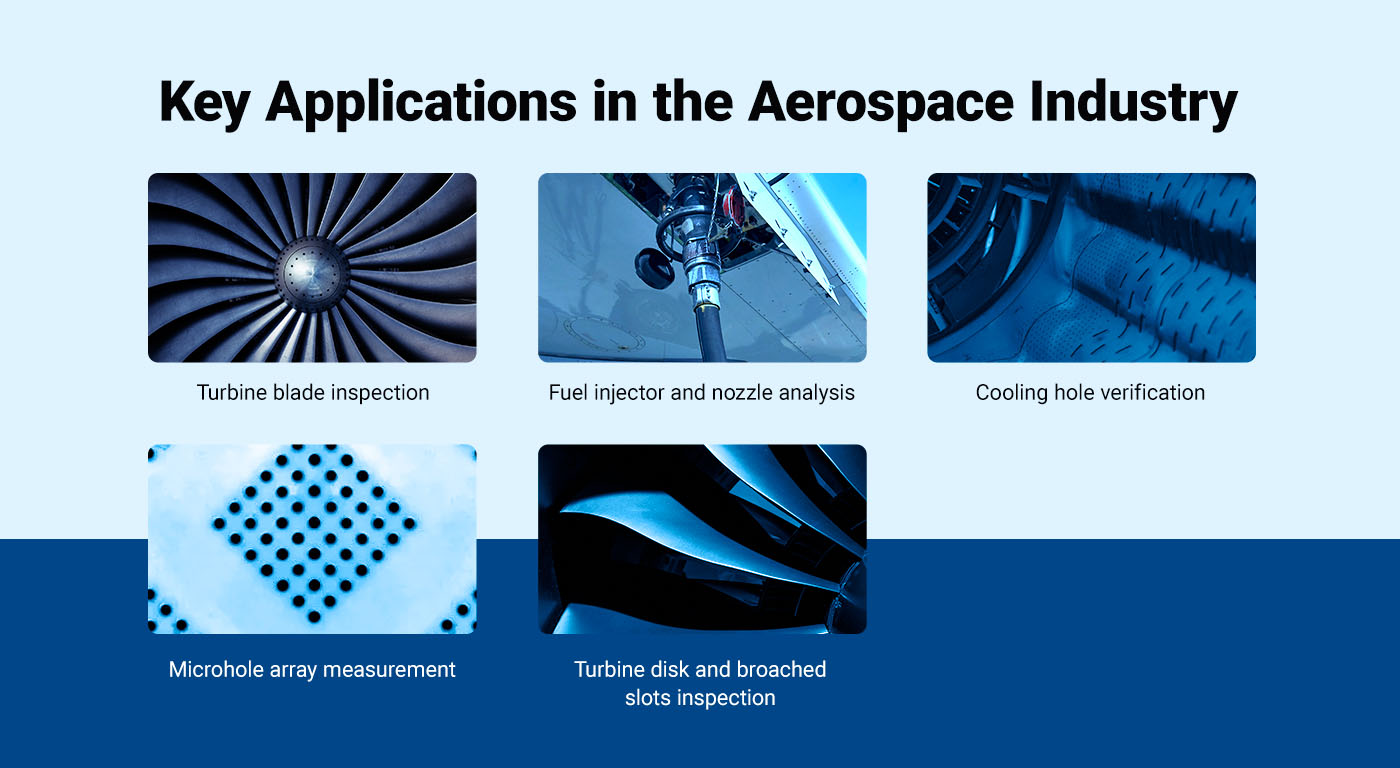

Key Applications in the Aerospace Industry

Here are some of the key applications for the VisionGauge® 700 Series Digital Optical Comparator:

- Turbine blade inspection: Checking turbine blade fir tree roots is critical for safety but is difficult to perform accurately manually. The VisionGauge® Digital Optical Comparator rapidly measures turbine blades against their CAD designs, with accuracy down to ±0.0001 inches.

- Fuel injector and nozzle analysis: Use our digital optical comparator to analyze microscopic fuel ports for blockage or geometric accuracy.

- Cooling hole verification: The 700 Series Digital Optical Comparator can quickly check thousands of cooling holes automatically to ensure they are present, open, and in the right place.

- Microhole array measurement: Some parts have many thousands of holes for other purposes, like acoustic attenuation or boundary layer control. The VisionGauge® 700 Series Digital Optical Comparator can verify these holes at scale across a variety of materials, including metal, ceramic, and silicon.

- Turbine disk and broached slots inspection: You can easily compare turbine disks against their CAD data or other standards with our digital optical comparator. This system also supports inspections for other aerospace parts, including blisks and EDM slots.

Process Comparison: Manual vs. Automated Inspection

Digital optical comparators for aerospace part inspection have a much more efficient process than manual inspection.

In a manual inspection, a technician places a part on a stage and uses a light source and overlays to check each part. The process is slow, subjective, and can only give 2D renderings of parts one at a time. For high volumes of parts, or parts with many thousands of holes to check, it could take days. One technician could pass a part that others might reject. The technicians would also need to manually input their results.

With the Digital Optical Comparator, the process is seamless. Parts can go directly from your EDM drilling machine to the inspection system by using the mounting system. This capability allows for fast, automatic inspection without re-fixturing. The machine spins the part, checks the points, and saves the data automatically. The system can also provide feedback to EDM programs by outputting hole offsets.

The Future of Aerospace Quality Control

The automatic inspection of aerospace components will play a key role as manufacturers move toward Industry 4.0.

In the future, aerospace parts may require digital product passports. These are secure digital files that travel with the part throughout its life. Digital passports contain all the data about where, when, and how it was made. Some major players in manufacturing already expect a digital thread to prove the authenticity and quality of the parts. The VisionGauge® 700 Series Digital Optical Comparator already provides this key information by saving an image and data for every inspection.

Engineers can use the data collected for digital passports to spot trends in manufacturing equipment like drills. As a result, you can predict the quality of the parts based on the wear of the machine you’re using. You can then repair or service the machine before it makes inadequate parts.

The VisionGauge® 700 Series can serve as an automatic quality control system within a closed-loop system. As the machine has external and internal input capabilities, it can talk to other machines like robot arms and PLCs. It can provide accurate robot positioning by inspecting the arm’s working area.

Choose VisionGauge® for Fast, Accurate Automatic Inspections

Inspecting aerospace parts at speed with precision gives you a competitive advantage. Reducing inspection time is crucial to reducing backlogs and meeting demand.

The VisionGauge® 700 Series Digital Optical Comparator offers a rapid and fully automated solution to inspecting holes in aerospace parts. With its increased speed, you can inspect aerospace parts more quickly, increasing throughput while minimizing quality escapes.

Get started by contacting us today.