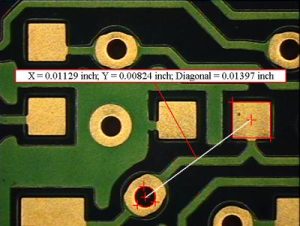

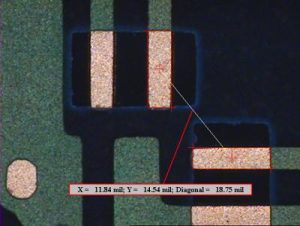

VisionGauge® OnLine is so accurate that measurements can be also performed on the cross-section of the board. Cross-section measurements are especially useful when checking the length of buried vias and thru vias.

The data obtained from these measurements can be easily exported, transferred, or placed into reports.

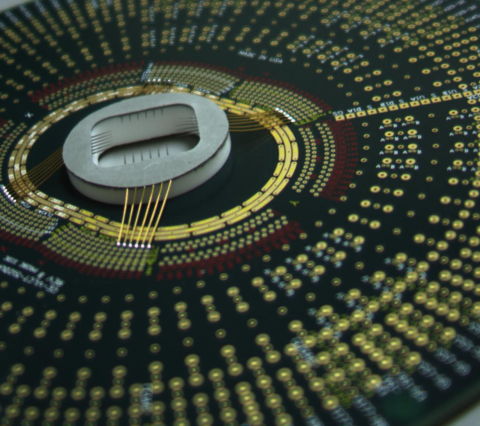

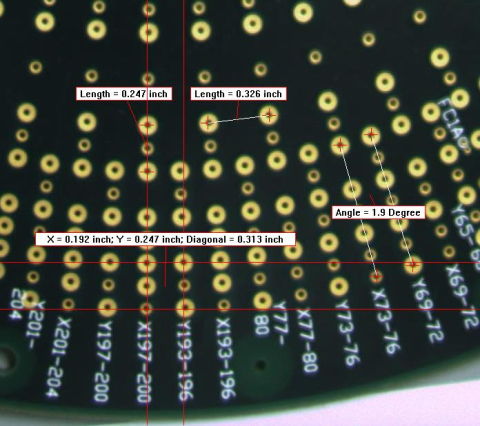

Probe cards are equipment used to test and benchmark semiconductor wafers. The thousands of sensitive probe needles present on a probe card can be placed as close as 20 microns apart and need to be placed precisely for the probing process to be successful. VisionGauge® OnLine’s Automated Optical Inspection (AOI) systems can carry out probe card measurement with great accuracy.

Our measurement systems are assembled with different levels of magnification, and they posses motion encoder accuracy up to 0.1 micron in three dimensions. VisionGauge® Online systems are easy to use and can be programmed so the inspection is fully automated, or you can use the system manually with the help of a joystick.

VisionGauge® Online includes many features to make your automated measurements effective and efficient. The software is capable of auto-focus, which provides you with accurate and highly repeatable results. These systems are also customizable with reflected or direct lighting.

You can automatically save measurement results, save the images with measurement tags attached to them, control input and output signals based on inspection results, and even automatically create reports with this information. For more information on any type of probe card measurement application with VisionGauge® Online machine vision systems, please contact us.

Information is also available about more recent applications solved with VisionGauge® Digital Optical Comparators.

Learn More