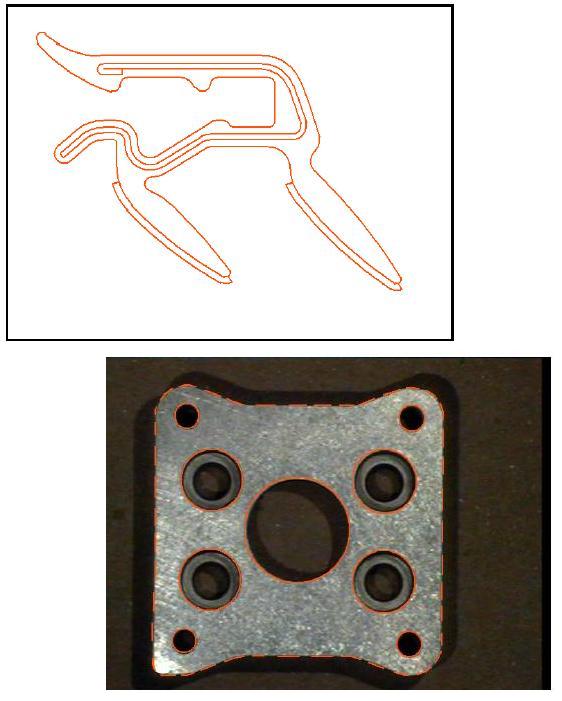

This is the perfect tool to use when comparing a part against its CAD drawing; VisionGauge® scales the CAD drawing appropriately and draws it “on top” of the part! VisionGauge®’s Live Image Overlay software tool with DXF-format CAD file support allows you to quickly determine how well a part matches up with its CAD file definition.

And when you use this tool with a stage (either manual or motorized), the overlay can move with the part. By having the overlay “track the part” in this way, you can carry out inspections and compare the part with the CAD overlay drawing at higher magnifications, outside of the field of view.

Other display options are also available: for example, you can scale the CAD drawing to fit inside the image or you can specify your own scaling coefficient.

For more advanced CAD overlay handling and part comparison, including our patented CAD Auto-Pass/Fail™ and CAD Auto-Align™ features, learn about our ground-breaking VisionGauge® Digital Optical Comparator systems.

Download a .pdf with information about VisionGauge®’s DXF overlay tools

VisionGauge®’s powerful Video Sequence Capture tool allows full frame-rate video capture (or slower, if specified by the user) to system memory. Once captured to memory, the video can be played back, modified, saved to disk, and retrieved later on, etc… The amount of video that can be captured (i.e. duration) is only limited by system memory.

VisionGauge® can save the video to disk as a sequence of individual bitmap images or as an “*.avi” movie file that can be played by other media applications. This tool is especially useful for time-dependent processes, motion tracking, etc…

In all cases, the video is captured and saved at full resolution and without compression, in full color and at full video frame-rate.

VisionGauge®’s Video Sequence Capture tool supports both analog and digital cameras.

Download a .pdf with information about VisionGauge®’s Video Sequence Capture tool.

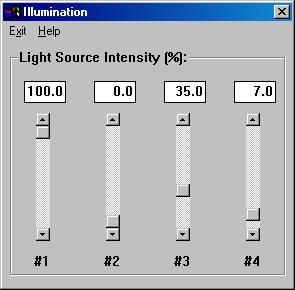

Download a .pdf with information about VisionGauge®’s programmable computer-controlled illumination.

With encoded motorized zoom optics, VisionGauge® is continuously aware of the system’s optical magnification as you zoom in and out. This means that VisionGauge® is able to:

VisionGauge®’s calibration procedure for encoded motorized zoom optics is very straightforward. The user begins by indicating the number of calibration points that he wants to enter and VisionGauge® distributes these points uniformly over the full zoom range of the optics. For each calibration point, VisionGauge® then brings the optics to the appropriate zoom position and prompts the user to carry out a simple field-of-view calibration. Once all of the points have been entered, VisionGauge® saves the calibration data to disk. This calibration data can be password-protected. VisionGauge® will then automatically read-in the calibration data on startup. And even though you only need to calibrate VisionGauge® at a limited number of zoom positions, VisionGauge® is able to carry out high-accuracy measurements at any position over the full zoom range of the optics by interpolating very accurately between the calibration points.

Motorized optics are another powerful tool that VisionGauge® puts at your disposal to easily and effectively solve difficult inspection and measurement applications.

Download a .pdf with information about VisionGauge®’s Motorized Zoom and Focus Optics.

Are you interested in streamlining your inspection process with VisionGauge® Digital Optical Comparators and optical measuring systems? As your vision inspection system manufacturer, we’re available to provide support at any time, so browse our selection of products or contact us online today.

Learn More