VisionGauge® High Accuracy 3D Inspection & Measurement Systems with built-in auto-focus and edge-detection are perfect for wide range of industrial production, quality control, and laboratory applications.

VisionGauge®’s advanced edge-detection technology produces sub-pixel accurate measurements, increases measurement repeatability, and virtually eliminates operator-dependent measurement error. Standard configurations are available off-the-shelf and non-standard configurations can also be accommodated. We can configure a system to meet your specific requirements!

These 3 dimensional inspection & measurement systems are built around the powerful and easy-to-use VisionGauge® software package, which means that they have a simple and intuitive Windows™ interface and include a wide range of fully-integrated tools for imaging, measurements, statistics, databasing, reporting (with charts & graphs), data transmission & exchange and much, much more!

We have recently launched a new generation of the VisionGauge® High-Accuracy Inspection and Measurement System that incorporates many enhancements that dramatically increase the speed, usability, and range of applications of these systems.

VisionGauge® 3D inspection & measurement systems also include a wide range of image analysis and measurement tools to allow you to successfully solve a wide range of applications. VisionGauge®’s powerful stage-based vision inspection tools include counting and sizing (blob analysis), registration and alignment, high-accuracy positioning and measurement, pattern matching, illumination control, auto-focus, step and repeat part scanning, color verification, defect detection, and many others.

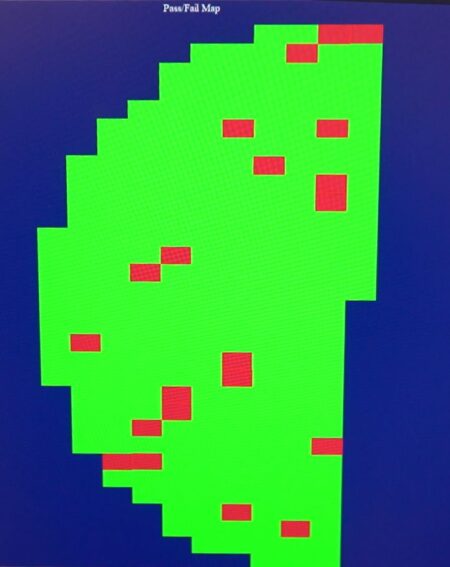

The latest generation of VisionGauge® systems include enhanced CAD-comparison capabilities optimized to support extremely large and dense CAD files, such as those typical of the semiconductor industry. With these latest enhancements, complete inspection programs can be built by importing the part’s CAD and tolerance data to take full advantage of our patented CAD Auto-Align™ and CAD Auto-Pass/Fail™ tools for 100% automated part-to-CAD comparison.

The systems also include the new VisionGauge® Report Builder™ which automates inspection results report generation for quality assurance and traceability. The VisionGauge® Report Builder™ is a powerful tool designed to streamline the process of creating, customizing, and sharing professional inspection reports. Built with efficiency in mind, the Report Builder integrates seamlessly with VisionGauge® measurement and inspection systems, to transform raw data into polished, customer-ready documentation. The Report Builder features enhanced capabilities that simplify report creation while giving users greater flexibility in personalizing reports to their specific requirements.

The new VisionGauge® High-Accuracy Inspection and Measurement Systems are also available with an automation module to allow them to easily be interfaced to external machinery, for example for automated part loading & unloading. This automation module includes all the necessary hardware & software full 2-way Ethernet (TCP/IP) communication as well as 2-way I/O communication (over 24 channels) between external machinery and VisionGauge®, for full “lights out” operation. With this new automation module, VisionGauge® is at the forefront of the automation revolution.

Another new VisionGauge® High-Accuracy Inspection & Measurement System improvement is the system’s enhanced defect map that allows for fast “big picture” results analysis as well as easier and more detailed “drill down” defect review.

Read a customer testimonial for a semiconductor flaw detection application.

Download a pdf about our High-Accuracy 3D Measurement and Inspection Systems.

Read our December 2025 press release “New Generation of VisionGauge® High-Accuracy Inspection & Measurement Systems Announced”