Efficiency, reliability, and precision are crucial in the ever-evolving world of medical device manufacturing. With advanced technologies like cameras, sensors, and computing systems, automation can further propel your manufacturing operations. Automation in medical device manufacturing can minimize human errors, ensure consistent output, produce reliable documentation, and meet stringent industry standards.

What Is Medical Device Automation?

Medical device automation includes technologies that help produce medical instruments and equipment without the involvement of human engagement and decision-making. These technologies include artificial intelligence (AI), robotics, and machine learning. The goal is to transform production methods into advanced systems that fulfill the demands of modern health care.

Automation was first used in manufacturing medical devices when basic mechanization was created. In the mid-20th century, it supported the mass production of a million disposable syringes for the polio vaccine — one of the first times a single medical device was produced at such a scale.

Over the years, technological advancements have introduced more sophisticated automation equipment in medical device manufacturing. There’s now computer-aided design simulation and computer numerical control machining, which have changed how medical devices are designed and produced. Robotics, AI, and the Internet of Things have only driven the automation shift, making processes faster and even more flexible. This efficiency is crucial when rising costs, labor shortages, and supply chain issues have become paramount in the industry.

Automated Medical Device Manufacturing Benefits and Roles

Automation fulfills several roles in the medical device industry, from meeting compliance to reducing production costs. It helps produce medical instruments with more accuracy and precision, assisting companies to stay ahead in a fast-changing industry.

Efficiency

While a common misconception about automation is that it eliminates jobs, it assists employees in various ways. Automation fulfills inefficient roles, allowing human labor to be reallocated to other areas. Laborers can take on safer and more interesting jobs that aren’t as physically taxing, increasing productivity. Automation also helps manage large and unexpected spikes in customer demand. This capability fosters a more stable baseline operation that can be scaled effectively to accommodate demand surges.

Compliance

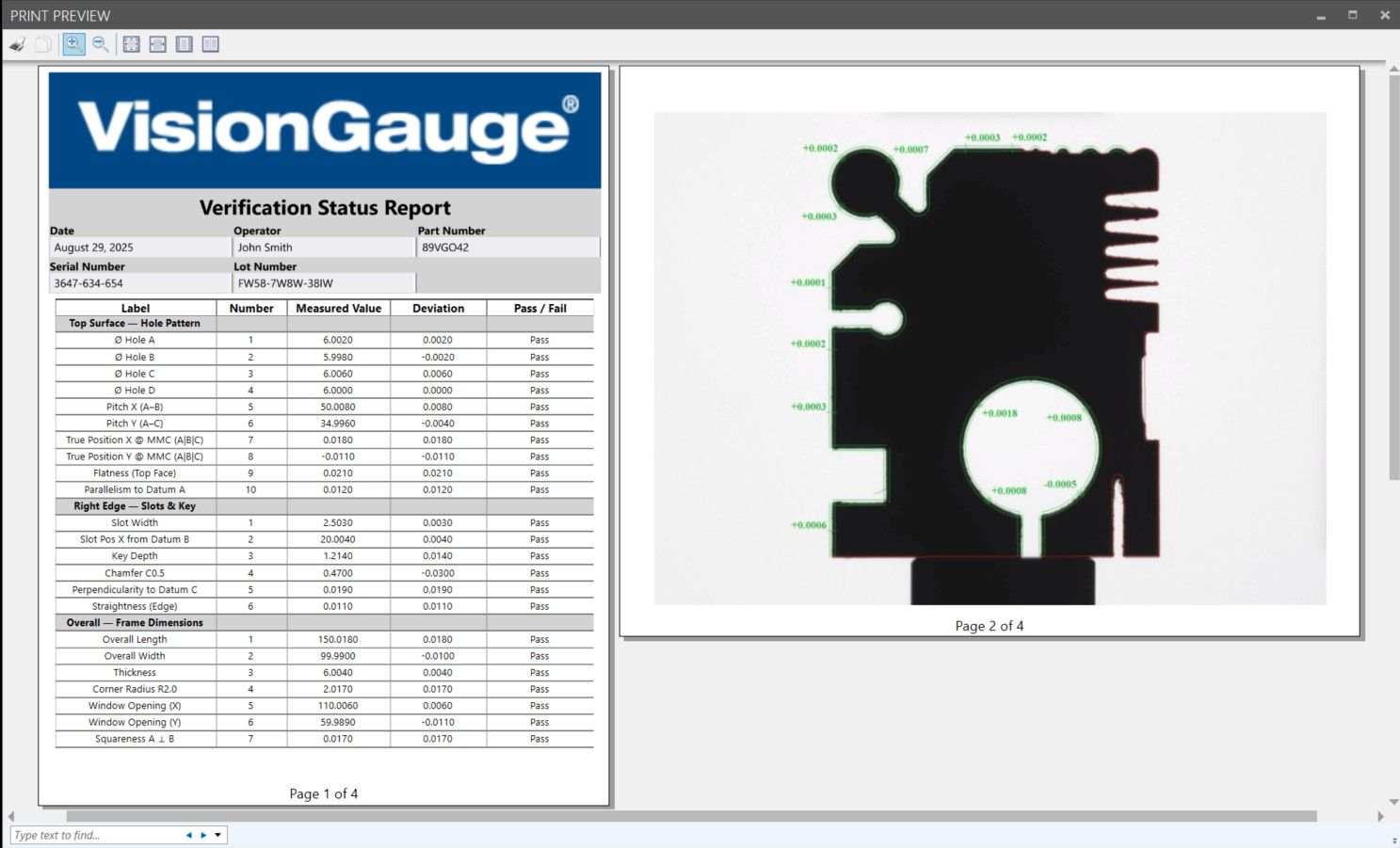

Compliance is crucial in the medical device industry. Automation can help you adhere to regulations set by organizations like the Food and Drug Administration and the International Organization for Standardization. For example, consistent documentation and traceability features can help you create consistent, quality devices that comply with specific standards.

Safety

Automation can fulfill simplistic or repetitive tasks, allowing employees to focus on safer tasks and reduce ergonomic-related injuries. For instance, over-molding requires properly forcing the seat to the first shot, which can lead to operator strain and discomfort. Personnel changes lead to increased variability, resulting in the same tasks being performed differently.

Moreover, due to the repetitive nature of the task, an operator can become distracted and neglect proper techniques or safety protocols. In that case, there’s a higher risk of human error, which can result in injury and quality issues. Automation creates consistency and eliminates the potential for human error and injury.

Accuracy

Automation makes part inspection and assembly much more precise. These systems use advanced imaging technologies and algorithms to inspect components and assemble them with unparalleled accuracy. Automation can inspect the part in situ and make the necessary adjustments in the manufacturing process, such as machining, to improve the accuracy of the product. For example, VisionGauge® systems can quickly and accurately detect the tiniest deviations in dimensions or surface finishes that might go unnoticed by human inspectors.

Cost Efficiency

Automation can lower the cost of manufacturing a medical device in several ways:

- Less reliance on manual work: Automation reduces the need for human involvement in tedious tasks, lowering labor costs and payroll expenses.

- Enhanced resource use and reduced waste: Material waste can lead to significant losses in time, energy, and revenue. Automated systems maximize your resources, resulting in efficient use and less material waste.

- Increased productivity: Automation enhances productivity beyond human capabilities, helping to reduce manufacturing time and expenses. It increases the output of your processes, leading to cost savings in production. Automation can also allow for “lights-out manufacturing,” which allows processes to continue around the clock without human supervision.

Types of Equipment for Increasing Automation in Medical Manufacturing

Common types of automated equipment used in medical device manufacturing include:

Collaborative Robotics

Automation doesn’t outright replace human labor. Rather, medical manufacturers use collaborative robots, or cobots, to support workers on the production floor. These cobots allow employees to focus on tasks that require human insight, such as problem-solving and creative thinking.

For instance, robots can handle a product’s heat-sealing processes, such as loading and unloading trays and lids from the sealing machine and then starting the heating cycle. They can perform these repetitive tasks with greater speed and accuracy.

AI-Powered Analytics

AI-powered systems can automate data analysis, predictive maintenance, and process optimization. These systems analyze massive datasets, allowing you to spot valuable insights for improvement. For instance, AI algorithms can forecast equipment failures before they happen, allowing manufacturers to execute proactive maintenance procedures to avoid downtime.

AI can also help you review key performance indicators and metrics. You can optimize manufacturing processes, boost productivity, and ensure consistent product quality.

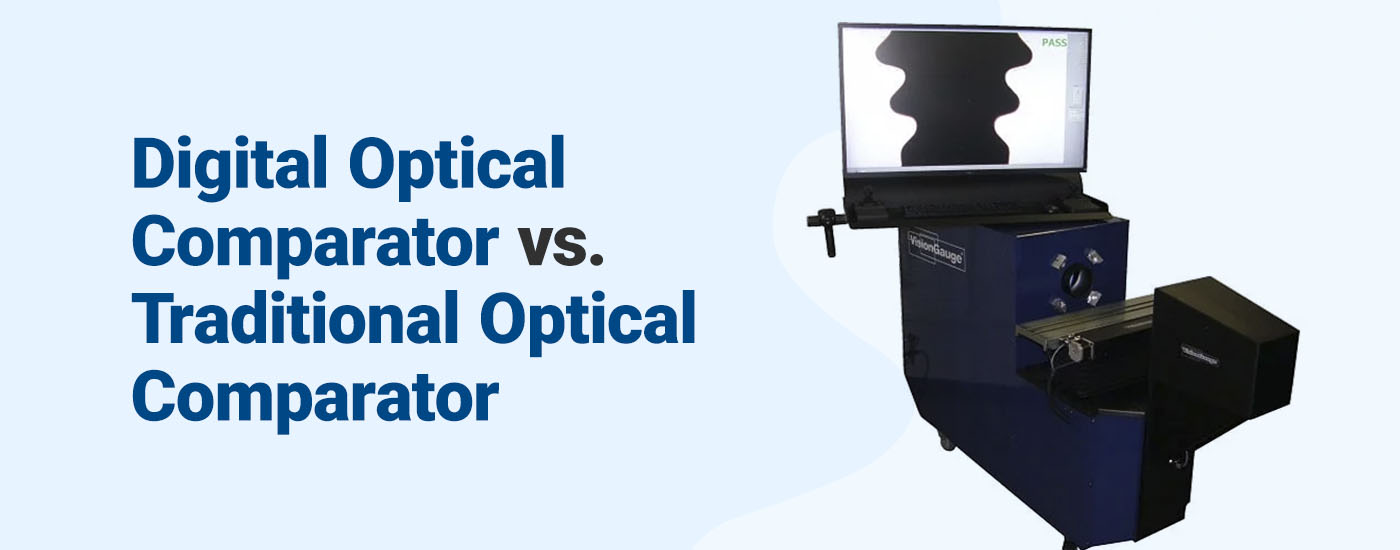

VisionGauge® Systems

VisionGauge® systems are advanced inspection systems that help improve automation through high-resolution cameras and sophisticated software. These systems take real-time measurements and inspect components faster and more accurately. They can detect defects early in production, providing immediate feedback on part quality to help you meet compliance.

Why Trust Us

At VISIONx, Inc., we take immense pride in our cutting-edge products and technical support services. Our VisionGauge® automation systems feature advanced engineering to suit your production needs. They can support manual or fully automatic inspections, precise part measurements, and excellent quality control. Our VisionGauge® Digital Optical Comparator and our versatile Standalone Inspection & Measurement System are ideal for integration into any current automated application.

We back our products with unparalleled support, whether you need help with a particular analysis or finding a suitable approach to a complicated challenge. See for yourself some of the many customers who have chosen us to conduct visual inspection and high-accuracy measurements.

Improving Your Operation’s Production and Efficiency With VisionGauge®

Automation can enhance efficiency, accuracy, and consistency in the manufacturing of medical devices. Overall, it can improve the quality of these instruments and help you stay ahead in a constantly changing industry.

VisionGauge® is designed for the precise inspection of medical device parts. It allows manufacturers to enhance product quality while reducing costs. Our systems support manual and automated inspections, streamline reporting, and easily interface with external equipment — making them a versatile solution for your manufacturing needs.

Contact us today to invest in our advanced patented technology or learn about our systems.