VisionGauge® High-Accuracy Field-Of-View Inspection & Measurement Systems are powerful, flexible, and extremely easy to use. They can be applied to solve a wide range of applications across many different industries.

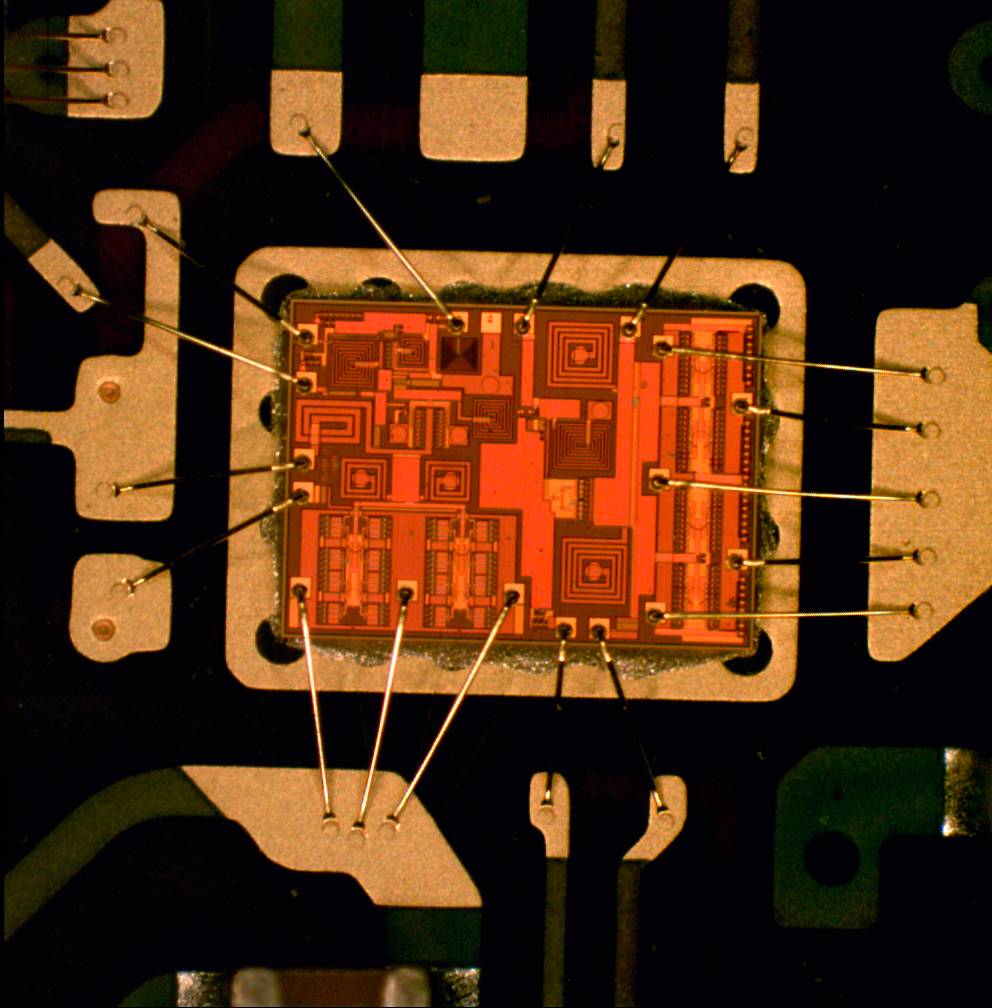

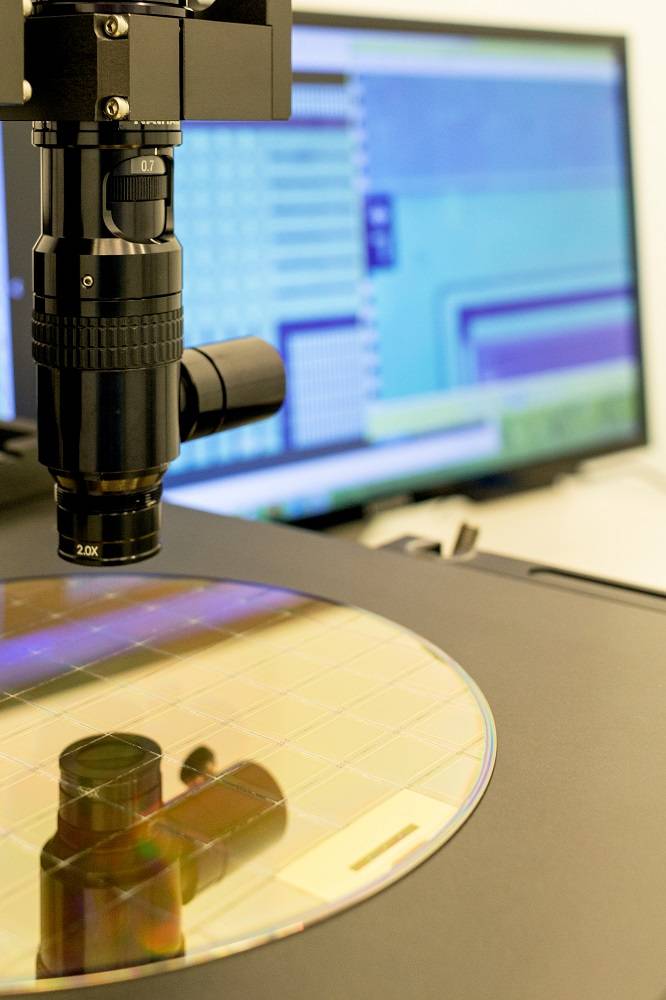

VisionGauge® High Accuracy Field-Of-View Inspection and Measurement Systems are available with either turret-based microscope type optics or with detented zoom optics. All of our industrial systems have a long working distance to provide ample clearance between the part and the lens.

All our VisionGauge® High Accuracy Field-Of-View Inspection and Measurement Systems run the VisionGauge® software package:

These network-ready Windows™-based systems are appropriate for both the shop floor and the QC lab.

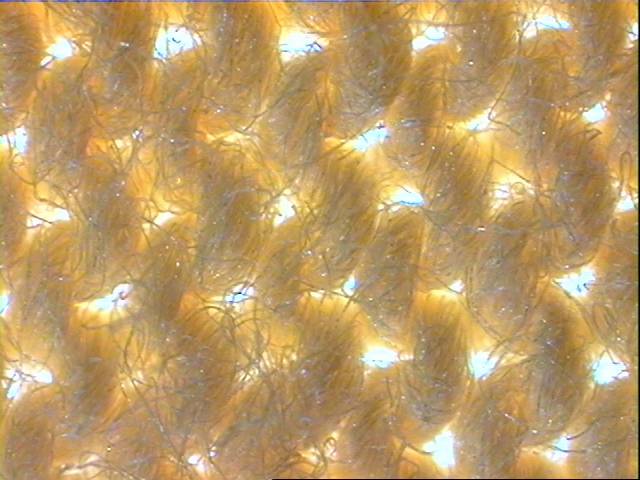

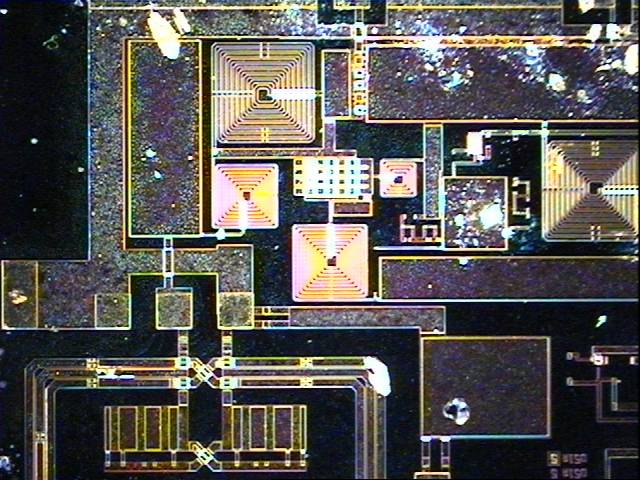

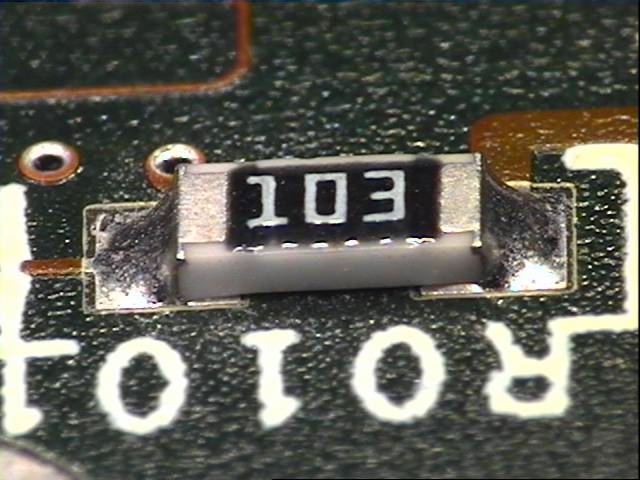

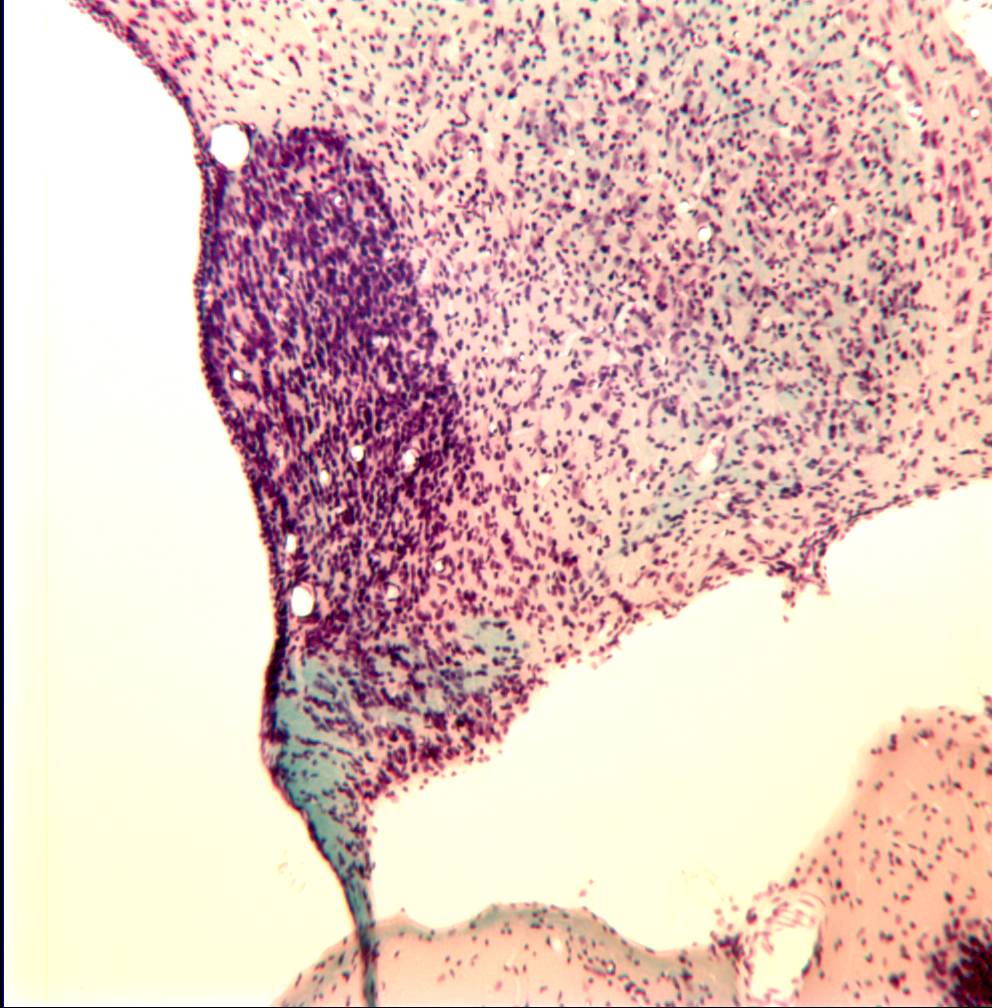

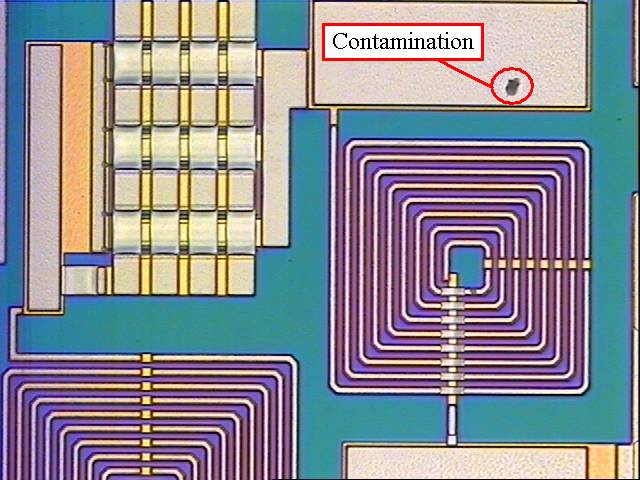

VisionGauge® High Accuracy Field-Of-View Inspection and Measurement Systems are perfect for wide range of industrial production, quality control, and laboratory applications.

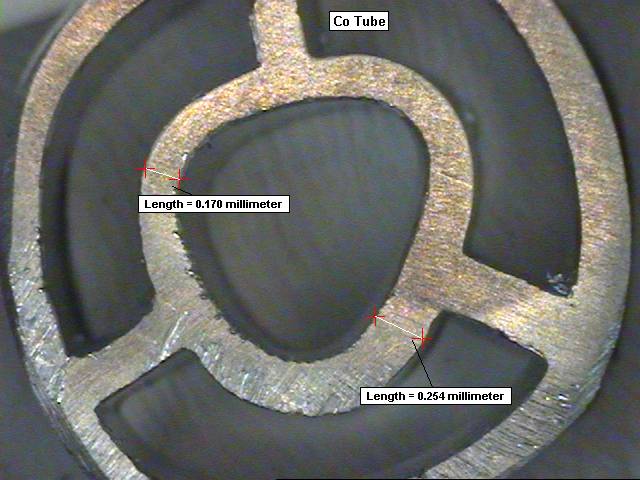

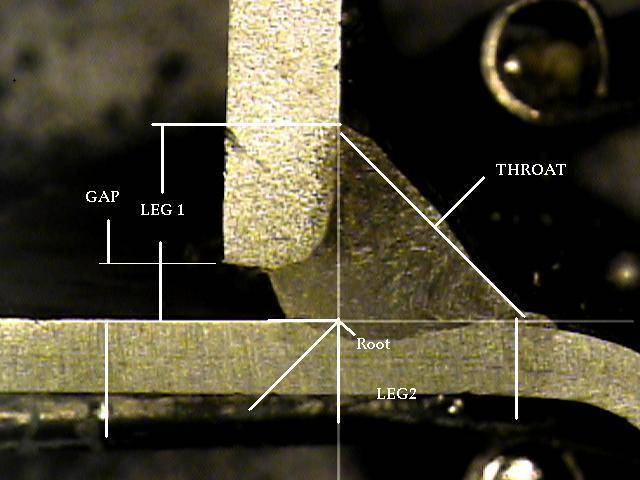

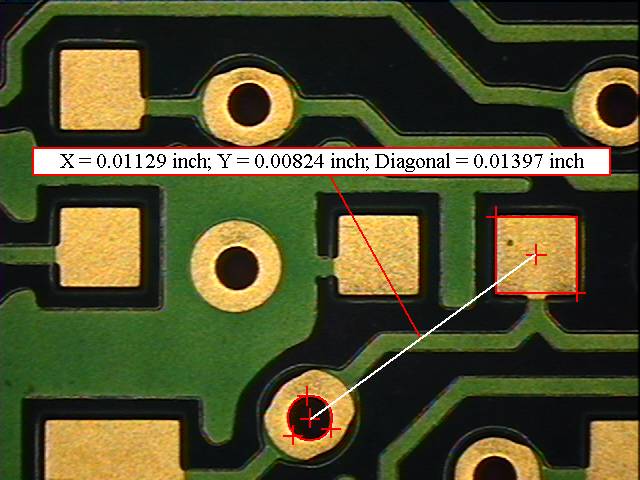

VisionGauge®’s advanced edge-detection technology produces sub-pixel accurate measurements, increases measurement repeatability, and eliminates operator-dependent measurement error. Standard configurations are available off-the-shelf and non-standard configurations can also be accommodated. We can configure a system to meet your specific requirements!

These inspection and measurement systems are built around the powerful and easy-to-use VisionGauge® software package, which means that they have a simple and intuitive Windows™ interface and include a wide range of fully-integrated tools for imaging, measurements, statistics, databasing, reporting (with charts & graphs), data transmission & exchange, and much, much more!

VisionGauge® 3D inspection & measurement systems also include a wide range of image analysis and measurement tools to allow you to successfully solve a wide range of applications. VisionGauge®’s powerful stage-based vision inspection tools include counting and sizing (blob analysis), registration and alignment, measurement, pattern matching, illumination control, color verification, defect detection, and many others.