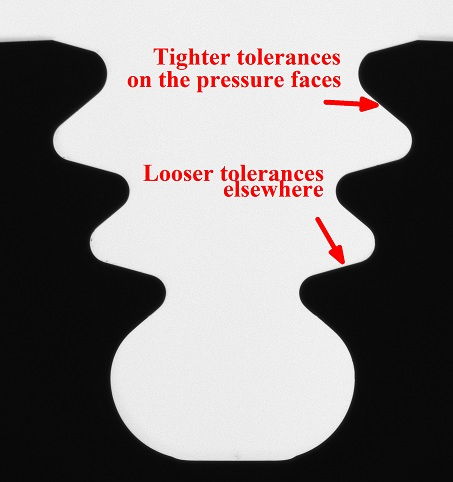

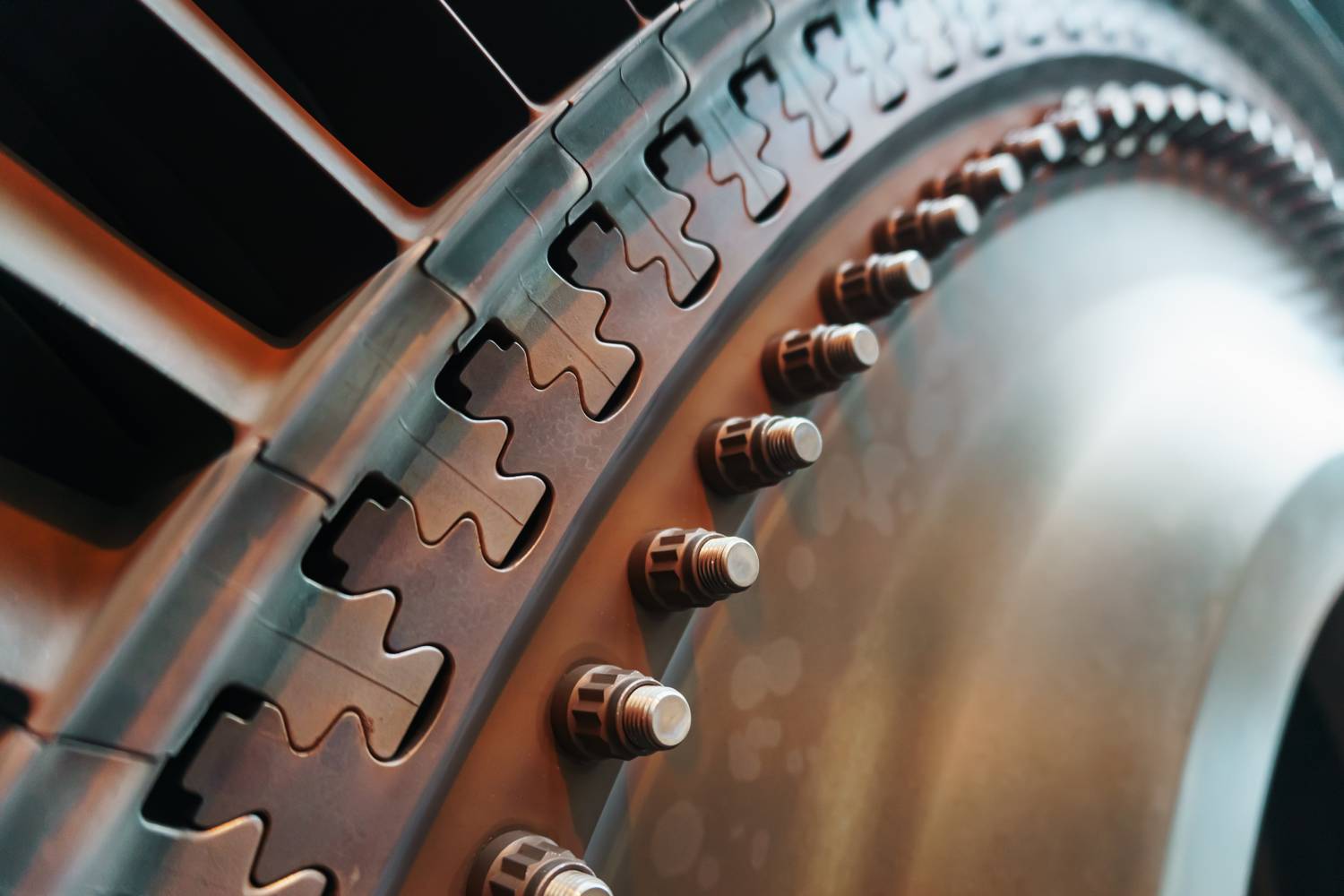

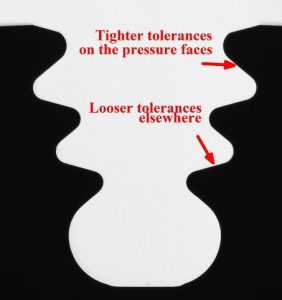

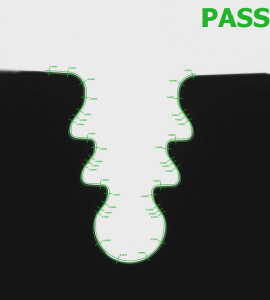

Turbine and compressor disk fir-tree slots and root forms are generally manufactured through broaching, wire cutting, or milling along with follow-up deburring and rounding operations. These features have complex geometries and very tight tolerances that are difficult to achieve. In particular, the pressure surfaces that constitute the critical point of contact between the blade roots and disc during operation are subject to very narrow tolerances in the order of 10–20 µm.

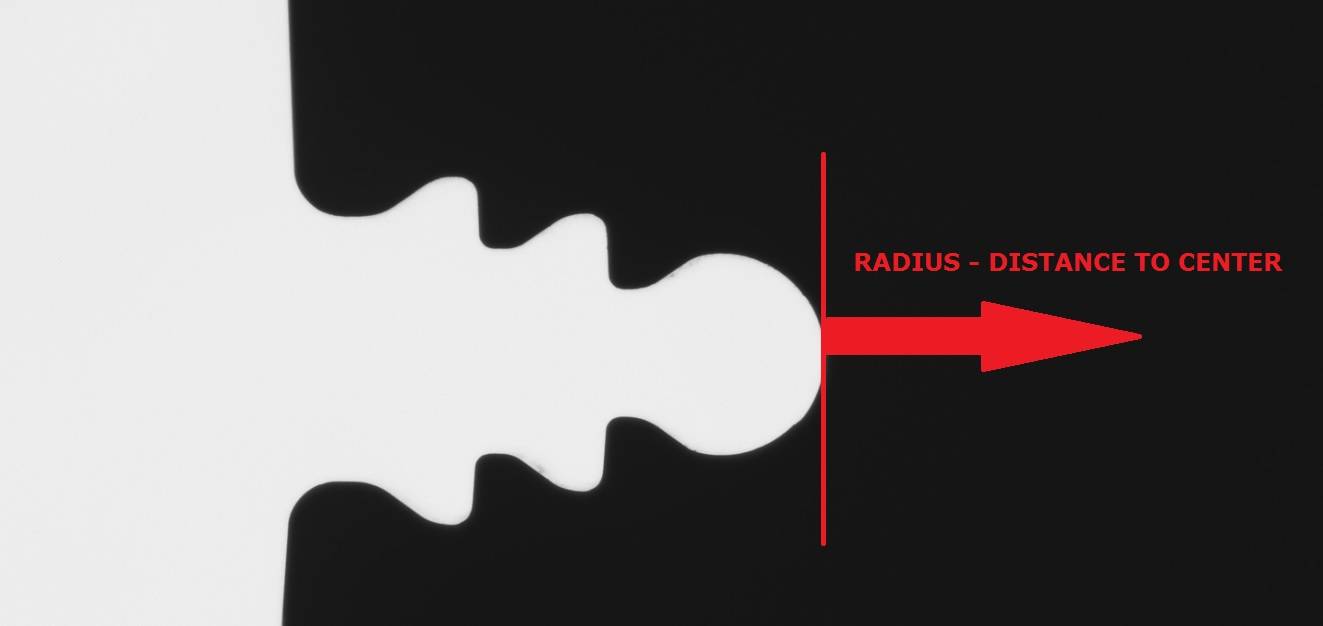

To ensure that the disk slots match up perfectly with the corresponding turbine blade shapes and provide proper performance, it is essential to accurately control the shape, position, orientation and alignment of the disk slots.

Some capabilities of the VisionGauge® Disk Inspection & Measurement System include:

VisionGauge® Disk Inspection & Measurement Systems can also be used to carry out complete reporting, data capture, and analysis, including:

allow you to automatically check the slot profile, get deviations from nominal, etc…

These very accurate tools produce results that are completely operator-independent