- Turbine blade inspection

- Defect detection in gas turbines

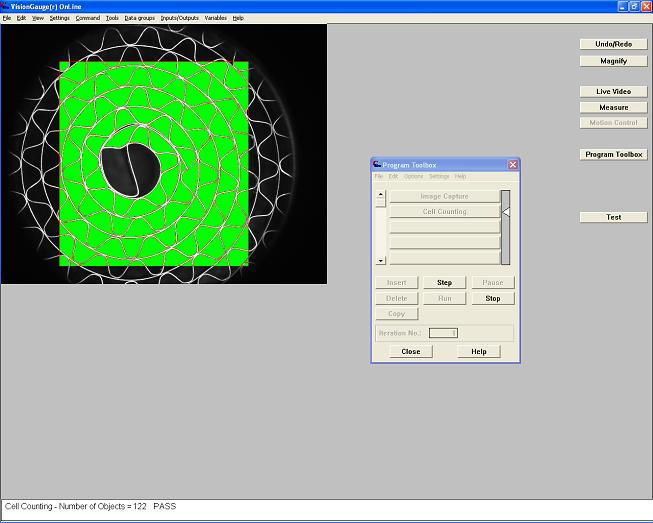

Our VisionGauge® products have been used across countless industries to solve a wide range of visual inspection and machine vision applications and other tasks. Below you will find a sampling of how some of our VisionGauge® products are still being applied, as well as information about our custom machine vision systems and imaging application development. Additional information about our current VisionGauge® Digital Optical Comparator applications can be found here.

All of our standard vision systems can be configured with different optics and components to meet various requirements. However, sometimes more customization is required to achieve all of the goals of an inspection system: This type of customization is something we do especially well.

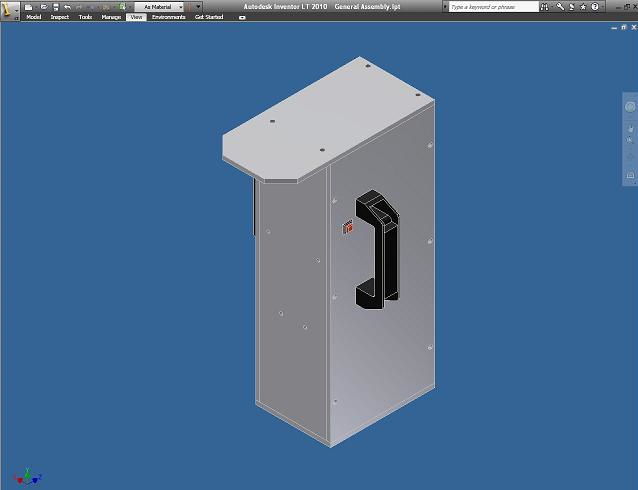

The process of developing custom machine vision systems designed to meet the requirements of a costumer’s application usually starts from a blank drawing board. Once the system goals have been identified, a group of our engineers will brainstorm ideas in order to find the most optimal solution to fulfill the customer’s needs. If system integration will be required, we may also need to understand the customer’s current processes to determine exactly how the system will fit. After a general idea of usage has been defined and some sketches are produced, the next step is to create a 3D physical model of the system for the customer’s approval.

If you have machine vision or imaging applications that you think might require some customizing, please contact us with the details of your project.

Learn More