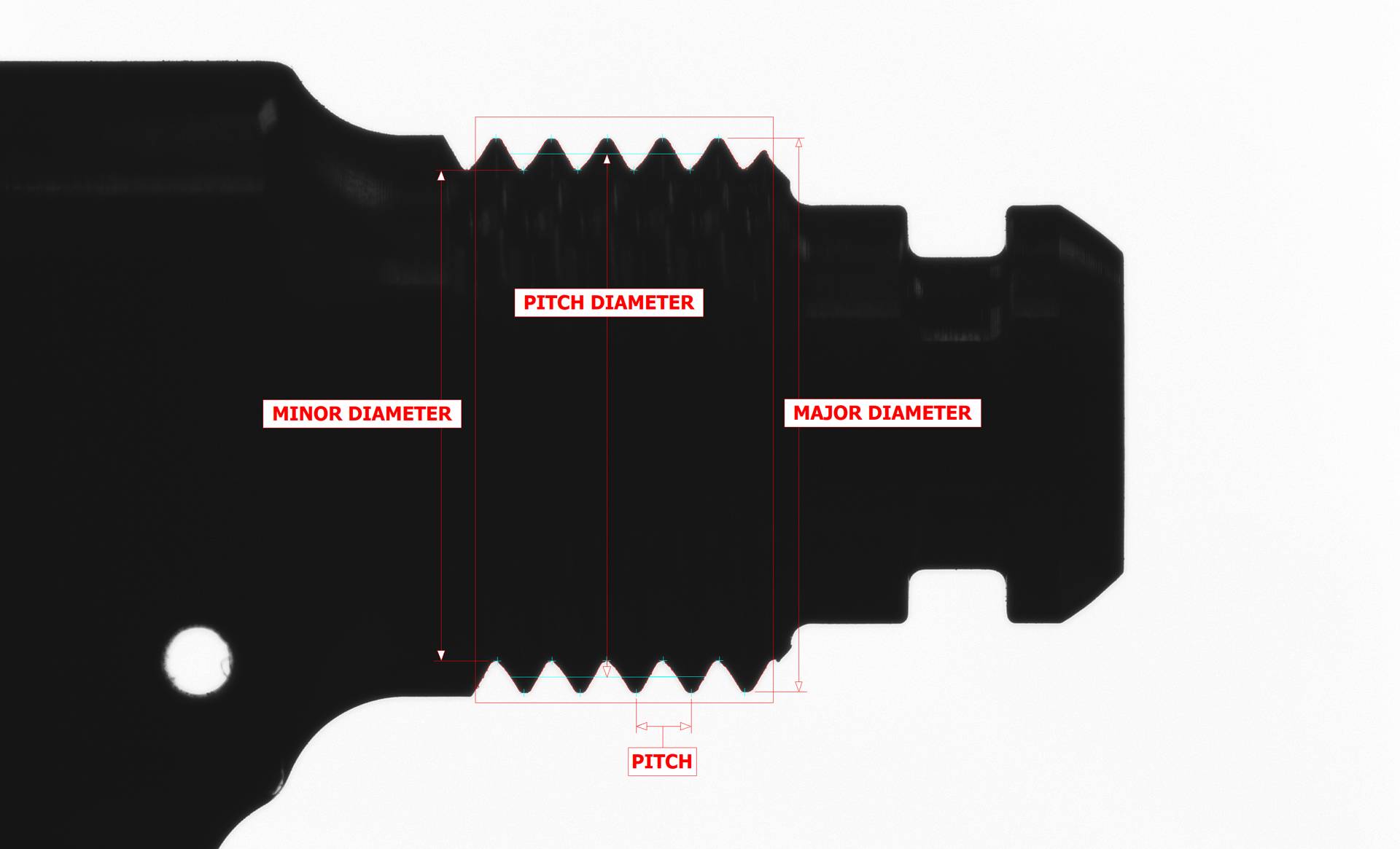

VisionGauge®’s advanced thread inspection tools perform automatic measurements on a wide range of parts with threads (not just limited to screws!). These non-contact measurements ensure that the related geometric aspects defining the threads conform to their manufactured specifications.

Thread measurement results are produced extremely quickly and can be included as part of an automated program or as a manual measurement by an operator. Completing thread measurements is as simple as selecting which measurements to report, then drawing a region of interest that includes the top and bottom threads. The tool is reliable and robust, and no mylars or overlays are required to complete the measurements.

Measurement tolerances can be applied for Pass/Fail values, and complete results can be sent to various output channels (collected in Data Groups, export to Excel, SPC software, text file, etc.).

With our supplementary rotary stage, thread runout can be easily measured by using the saved centers as datums.

Download the Thread Inspection and Measurement Application Note in .pdf format.

Results are fast, accurate, and fully-automated, producing operator-independent results each time.

Contact us with your application requirements, and visit our Applications page for more examples of applications VisionGauge® Digital Optical Comparators can solve.

Learn More