The VisionGauge® OnLine software drives the VisionGauge® Digital Optical Comparator. This powerful machine vision software for automated inspection, verification, and data collection includes state-of-the-art vision tools for defect detection, pattern matching, automated measurement, optical character recognition, blob analysis, and much more. VisionGauge® OnLine features exclusive tools for use with our VisionGauge® Digital Optical Comparators, many of which are listed below.

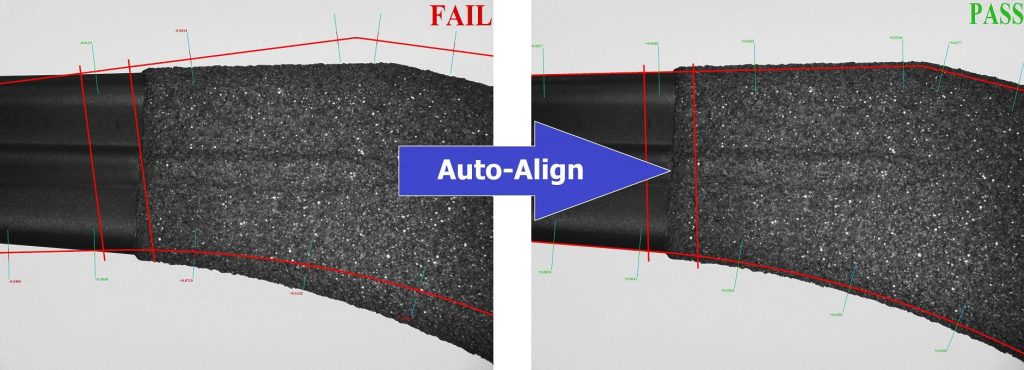

The VisionGauge® Digital Optical Comparator’s ground-breaking CAD Auto-Align™ tool automatically aligns the CAD data to the part, drastically reducing inspection times and obtaining increased accuracy.

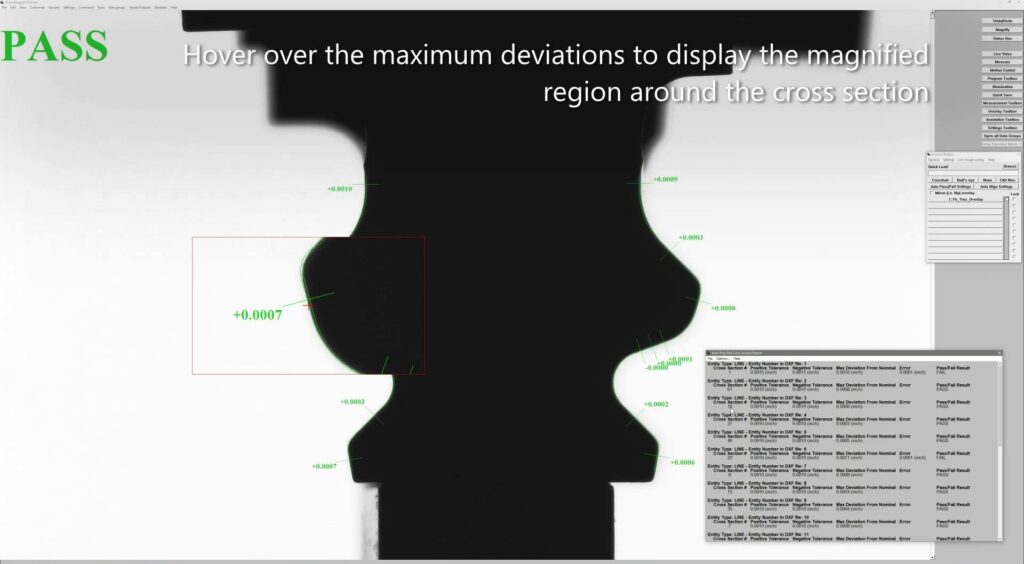

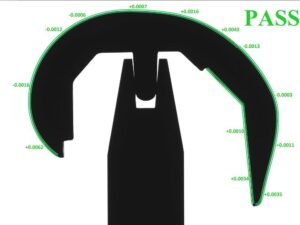

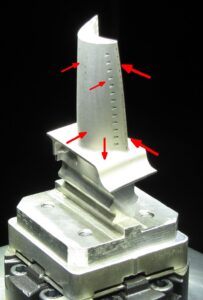

The VisionGauge® Digital Optical Comparator’s patented CAD Auto Pass/Fail™ tool accurately computes and displays, in real time, a part’s deviation from nominal, to automatically determine with a Pass/Fail result if a part is within tolerance.

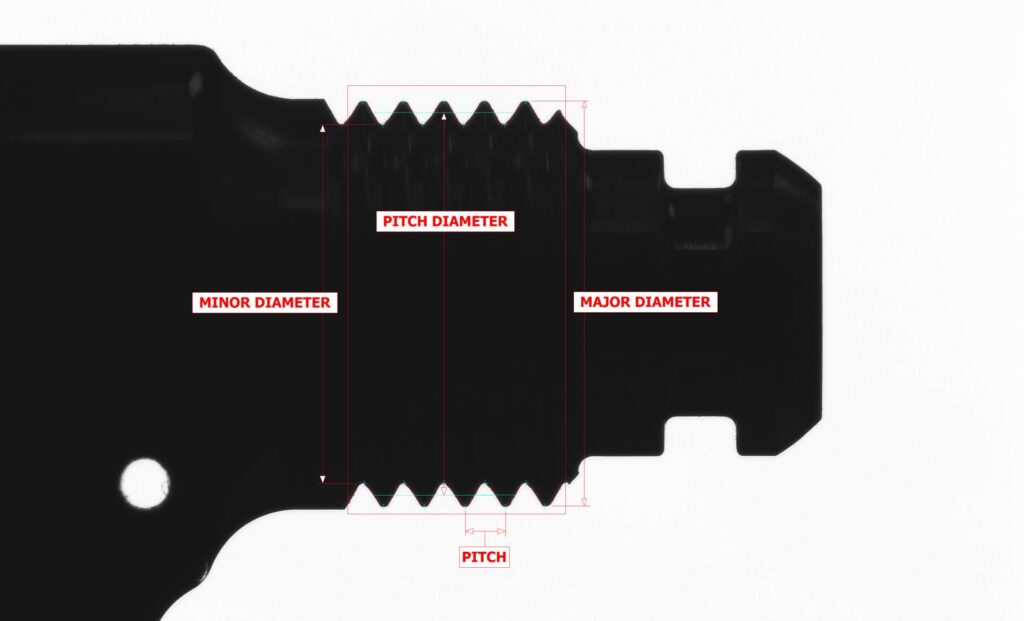

VisionGauge®’s powerful and innovative new patented “Tooth Checker™” tool automatically locates, to very high accuracy, the crests and / or roots of a part’s teeth or threads and determines if they are within their tolerance band.

VisionGauge®’s Advanced Auto-Pass/Fail Analysis and Report tools allow operators to easily review, explore, and label CAD Auto-Pass/Fail™ results at each cross section of interest in the field-of-view.

VisionGauge® OnLine has an easy and intuitive interface for specifying tolerances on CAD overlay files used with the CAD Auto-Align™ and CAD Auto-Pass/Fail™ tools. You can also read-in tolerances directly from the CAD file. Multiple tolerance types are supported with different display options.

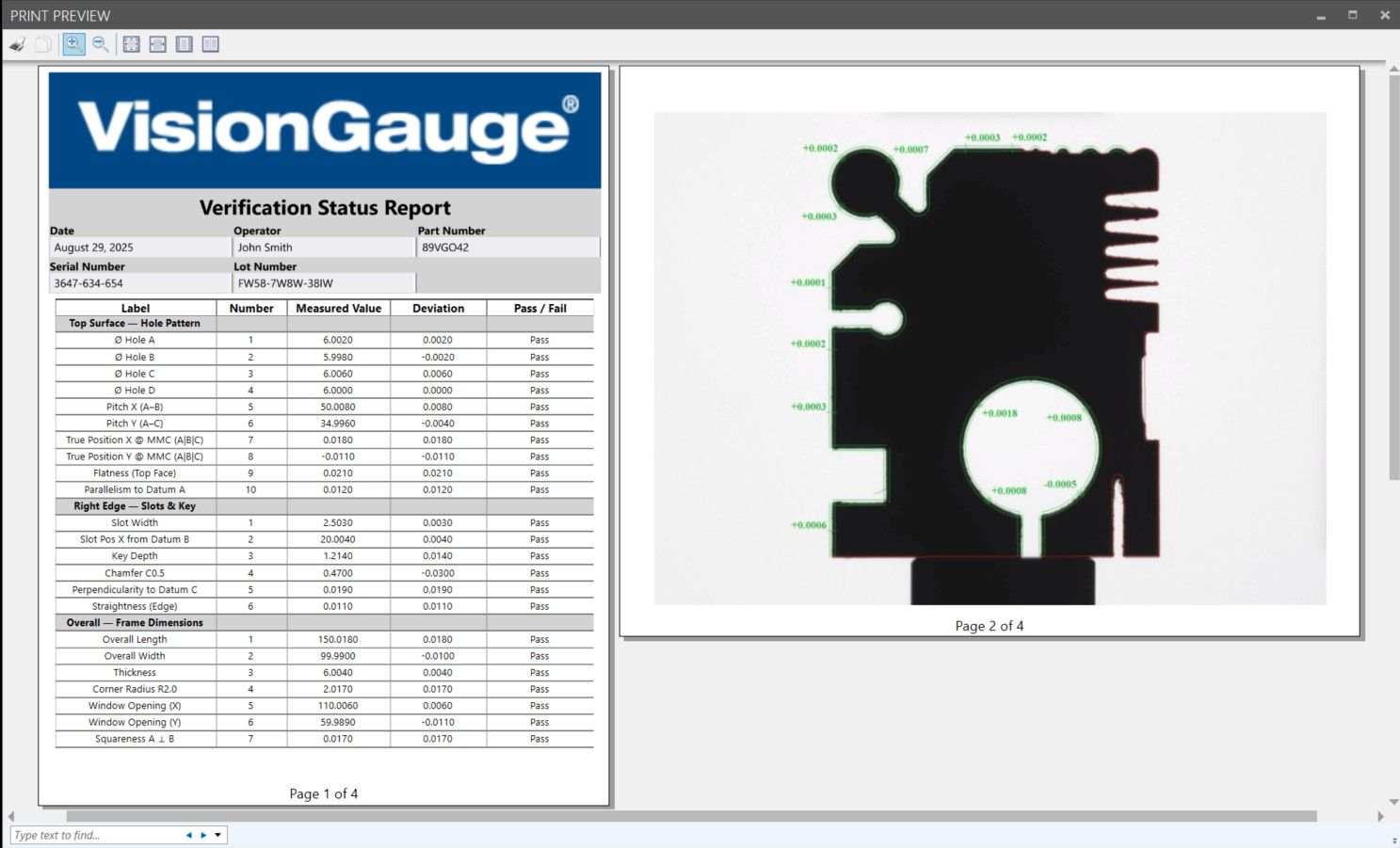

The new VisionGauge® Report Builder streamlines the process of creating, customizing, and sharing professional inspection reports, directly from the inspection machine and without operator intervention. Automatically populate templates for your measurement result reports and database or print them for complete device inspection history.

Easily define features with datums, then automatically determine if the Actual occurrence of a feature falls within the Nominal’s allowable tolerance zone with VisionGauge® OnLine’s True Position measurement tool (Position Tolerance).

The VisionGauge® “Part Reorientation” tool is a powerful and intuitive tool to carry out 6-point iterative alignment, even on parts with complex geometries. The tool converges quickly to a stable and accurate solution and applies the corrections to part inspection programs.

VisionGauge®’s Edge Break Measurement tool automatically locates to high-accuracy, the edge breaks of lines – including sharp, rounded, and chamfered edges. Lines are automatically calculated at any orientation and there are no limitations to the angle at which the edges meet.

The new VisionGauge® Thread Inspection and Measurement tools are designed to meet strict quality inspection requirements with automatic measurements on various types of parts with threads, extremely quickly and to high accuracy.

Pattern Matching Tools

Pattern Matching ToolsVisionGauge® includes powerful pattern matching tools useful in solving a wide range of applications. These robust tools can quickly and accurately identify and locate objects and features without limitations.

VisionGauge® Remote Program Communications features makes it easy to interface with a robot or other part-positioning equipment to fully automate and coordinate quality inspection operations.

Are you interested in streamlining your inspection process with VisionGauge® Digital Optical Comparators and optical measuring systems? As your vision inspection system manufacturer, we’re available to provide support at any time, so browse our selection of products or contact us online today.

Learn More