Surgical and medical instruments play a critical role in a wide range of medical procedures and can directly impact patient safety and outcome. It is of paramount importance for medical device manufacturers to ensure that the various surgical and medical instruments they produce meet all their design requirements and dimensional characteristics.

The 500 Series VisionGauge® Digital Optical Comparator is the ideal solution for achieving this goal. It was designed in close collaboration with a large medical OEM and it has the flexibility to handle the wide variety of surgical and medical instruments that exist. The system can verify all the complex features found on surgical and medical instruments and meet the wide range of measurement requirements these parts can present.

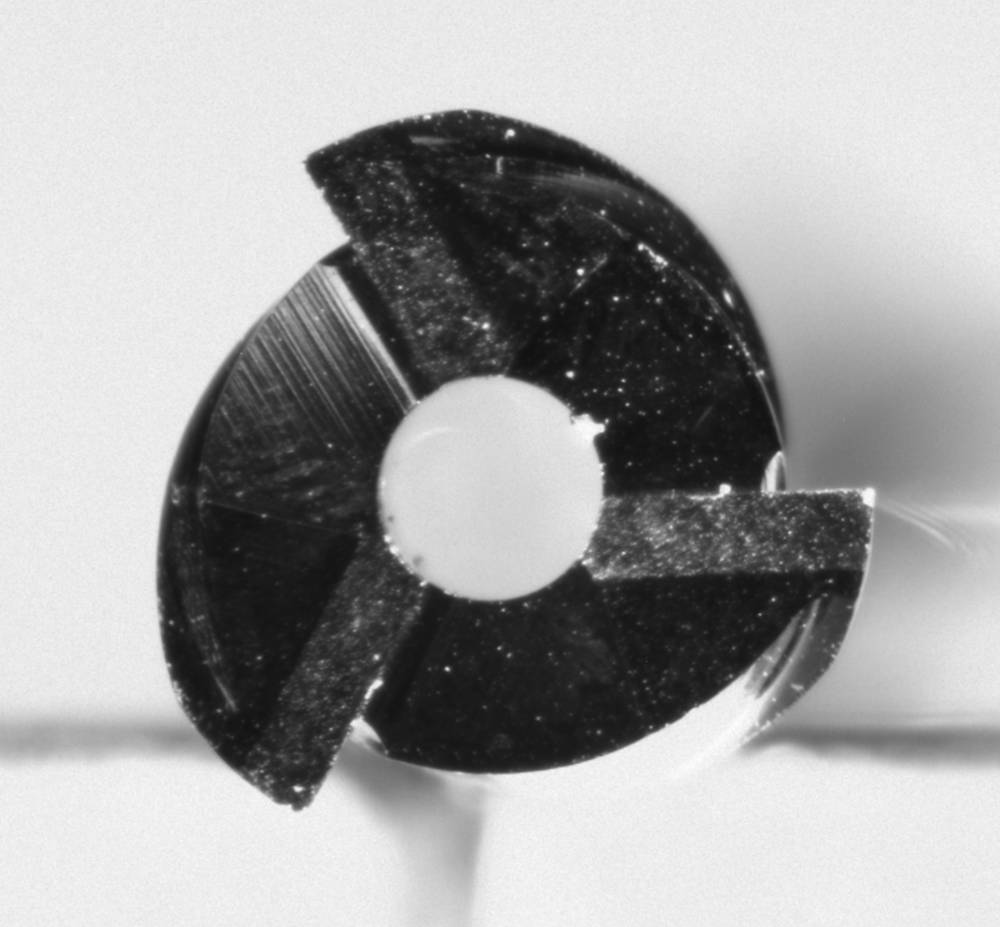

Our digital optical comparators are a non-contact solution that provides transmitted as well as various types of on-axis and oblique reflected illumination to allow users to inspect all areas of the parts, even those with very complex geometries!

Because it’s a fast system that can be used directly on the production floor, when it identifies a defect users can often take direct corrective action and remedy the problem, rather than continuing adding value to an out-of-spec part. The VisionGauge® Digital Optical Comparator really does make the measurement process more efficient and helps reduce cost for manufacturers. It allows them to increase productivity and shorten inspection & measurement times.

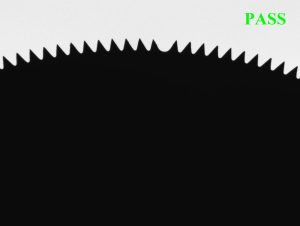

The VisionGauge® Digital Optical Comparator offers a deep toolbox of specialized inspection and measurement modes to enable, for example, the accurate measurement of the location of grooves, markings and other types of unconventional features that specialized medical instruments can display. The system is also ideal for dealing with complex surfaces and geometries and parts made of unconventional and difficult-to-measure materials.

The VisionGauge® Digital Optical Comparator is a multi-purpose machine that has the flexibility to support the quality needs of the full range of products produced by medical manufacturers.

With VisionGauge®, instruments with cutting edges such as scissors, rongeurs, chisels, curettes, etc., can be checked for sharpness and to ensure that there are no dull spots, chips, or dents. Hinged instruments such as clamps and forceps can be checked for alignment of jaws and teeth. And so on… The system’s great ease-of-use and flexibility make it the ideal solution for just about every type of medical instrument.

The VisionGauge® Digital Optical Comparator delivers maximum performance and is ideal for fast and automated data collection & reporting. It is perfect for ensuring the traceability of medical instruments!

There are many reasons why the VisionGauge® Digital Optical Comparator is widely used by many manufacturers in the medical industry – both large and small – to check medical instruments:

The VisionGauge® Digital Optical Comparator is rapidly becoming the new standard for inspecting instruments in the medical industry.