Fast and Accurate Hole Inspection with VisionGauge® Digital Optical Comparators

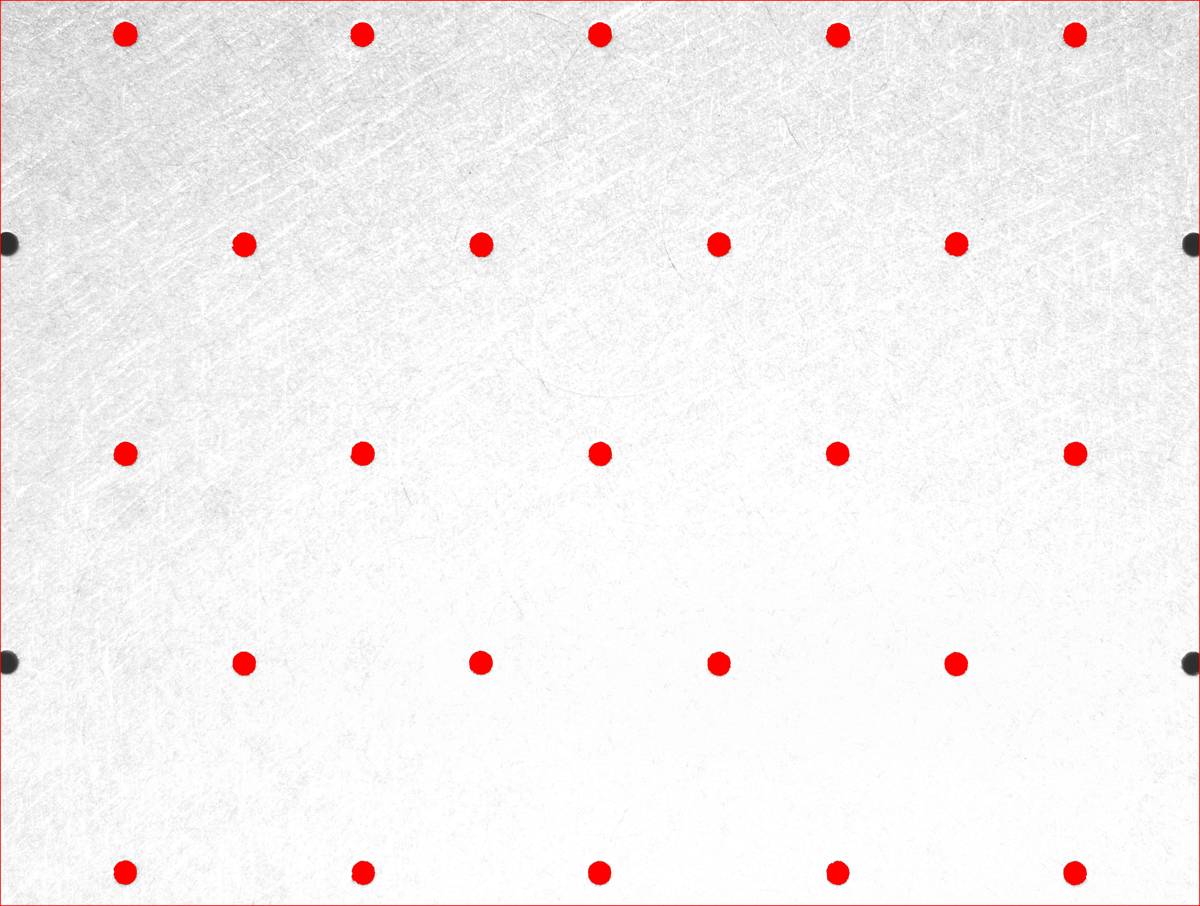

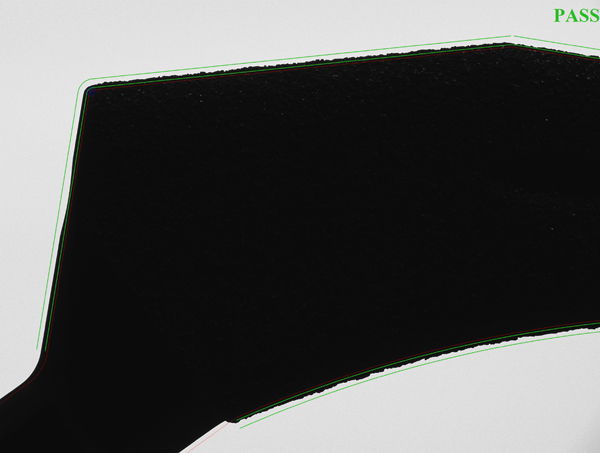

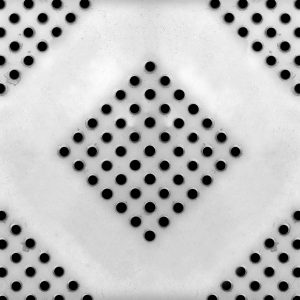

Typically, the inspection needs to ensure that all of the holes are present and that their location and geometry are correct. Note that, in some cases and depending on functional requirements, the holes might not necessarily be round. In fact, we’ve come across quite a wide range of different hole geometries in these types of projects.

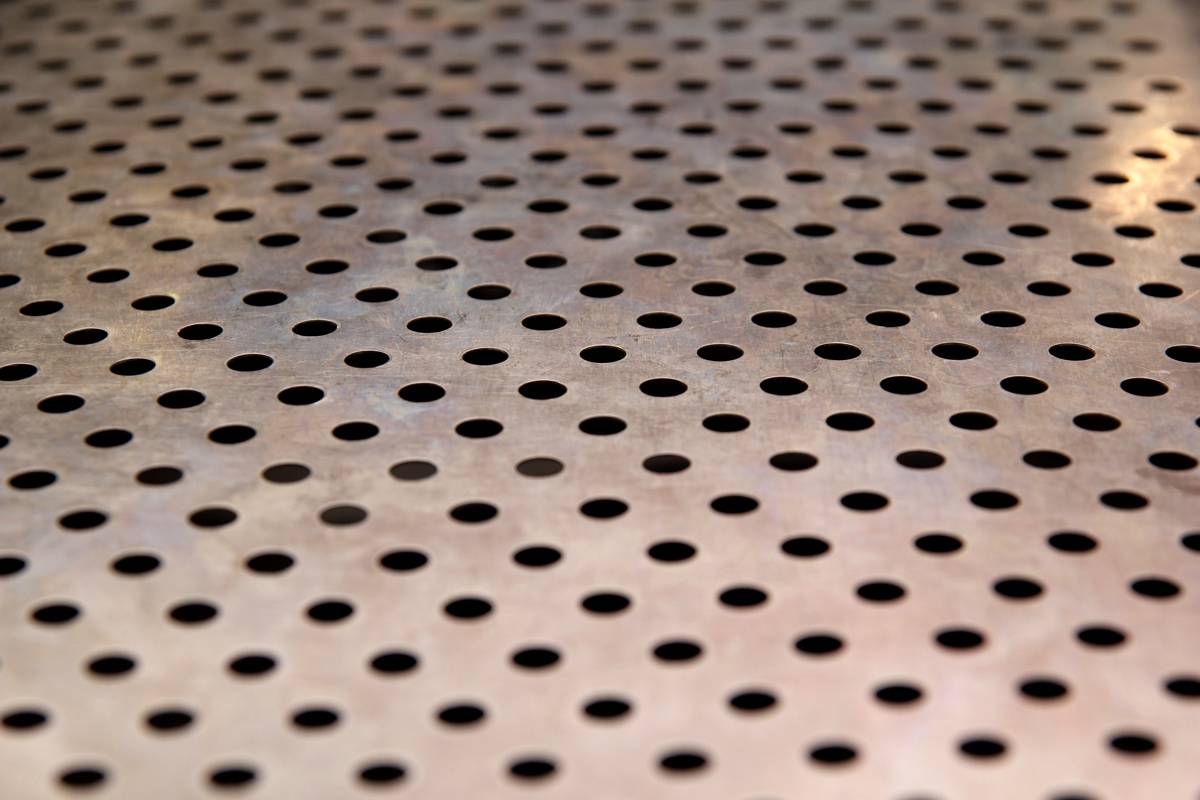

Inspecting 100% of the holes can be both challenging and extremely time consuming. Most inspection systems, to obtain the needed level of detail, proceed hole-by-hole. If a part has 18,000 holes, for example, then even if every individual hole can be dealt with quickly, this approach still takes a tremendous amount of time to cover the entire part. We’ve heard of parts for which a complete inspection required full days and even multiple days.

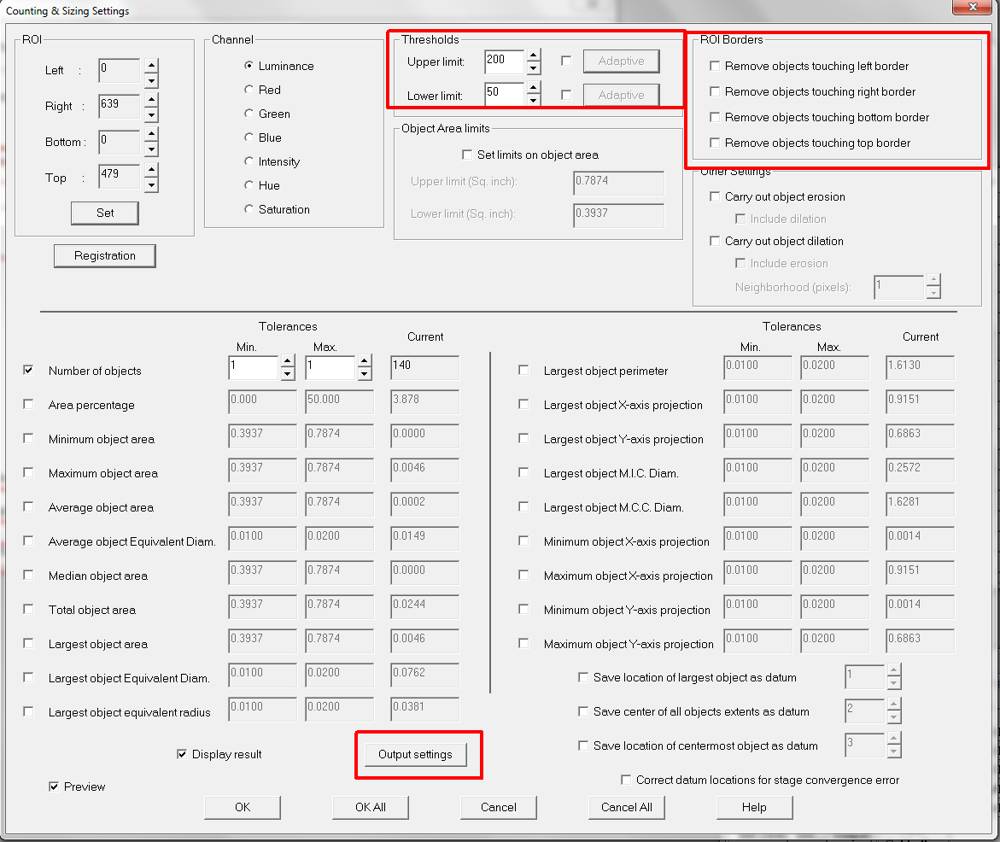

The VisionGauge® Digital Optical Comparator is especially well suited to applications where parts have a very large number (e.g. many thousands) of closely grouped holes as it can analyze all of the holes visible in the entire field-of-view at once, very quickly and accurately. This approach involves absolutely no compromise on accuracy. All the while, throughput is increased tremendously.

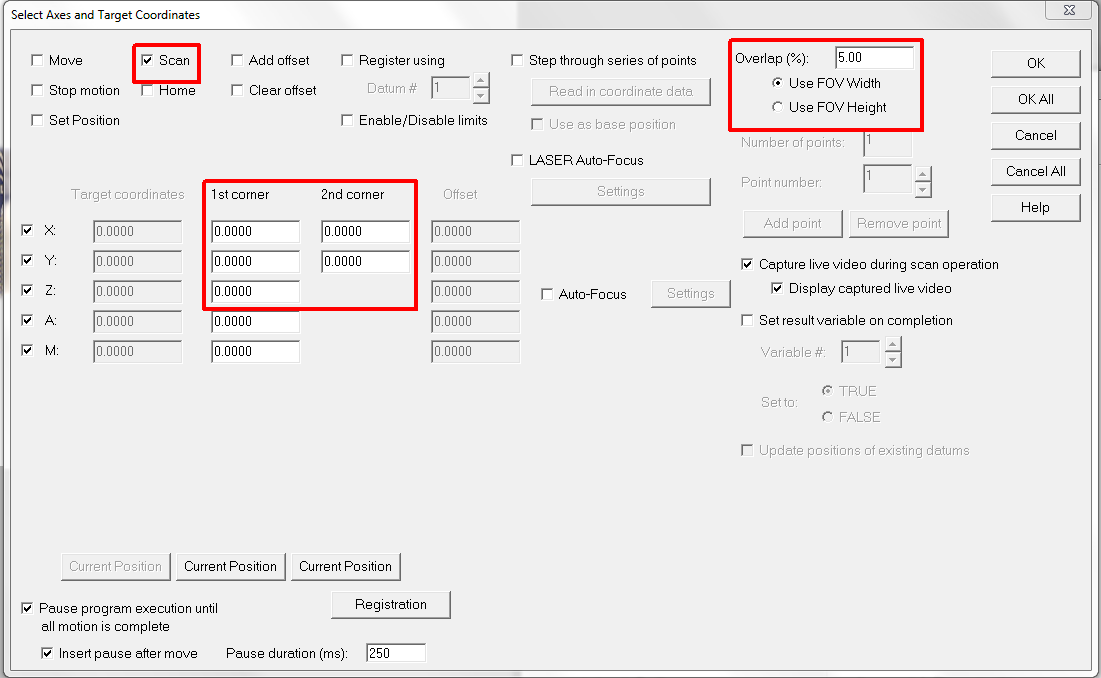

Motion operations (i.e. physically moving the part or the camera) are typically the most time-consuming steps in inspection and measurement programs. In applications involving a large number of closely grouped holes, the optimized approach offered by VisionGauge® drastically reduces the number of motion operations needed since it doesn’t involve hole-by-hole movement but rather simply ensuring that the entire part has been scanned through field-of-view-by-field-of-view coverage.

Furthermore, VisionGauge® can analyze every individual hole in the field-of-view extremely quickly (e.g. milliseconds) as it captures a great many measurement points (typically: thousands) almost instantly.

Some applications involve parts with a great many holes (for example: many thousands) that need to be checked. These parts can be made of different materials. We’ve worked on metal, carbon, ceramic and silicon parts like this. These parts are sometimes referred to as hole arrays or micro hole arrays.

Some applications involve parts with a great many holes (for example: many thousands) that need to be checked. These parts can be made of different materials. We’ve worked on metal, carbon, ceramic and silicon parts like this. These parts are sometimes referred to as hole arrays or micro hole arrays.