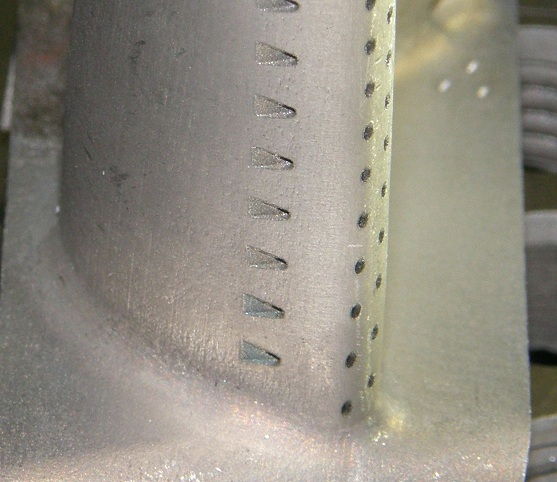

In modern aircraft engines and industrial gas turbines (IGT) combustor exit gas temperatures exceed the melting point of the turbine engine materials. Running hotter enables engines to maximize efficiency and minimize fuel consumption. To protect the engine components that are subjected to these too-high temperatures, patterns of small holes – called cooling holes – are strategically placed to allow (relatively) cooler air to be injected and form a thin protective layer over the material surface. Without this protective film of cooler air, of the engine components subjected to the highest temperatures would literally melt, leading inevitably to catastrophic engine failure.

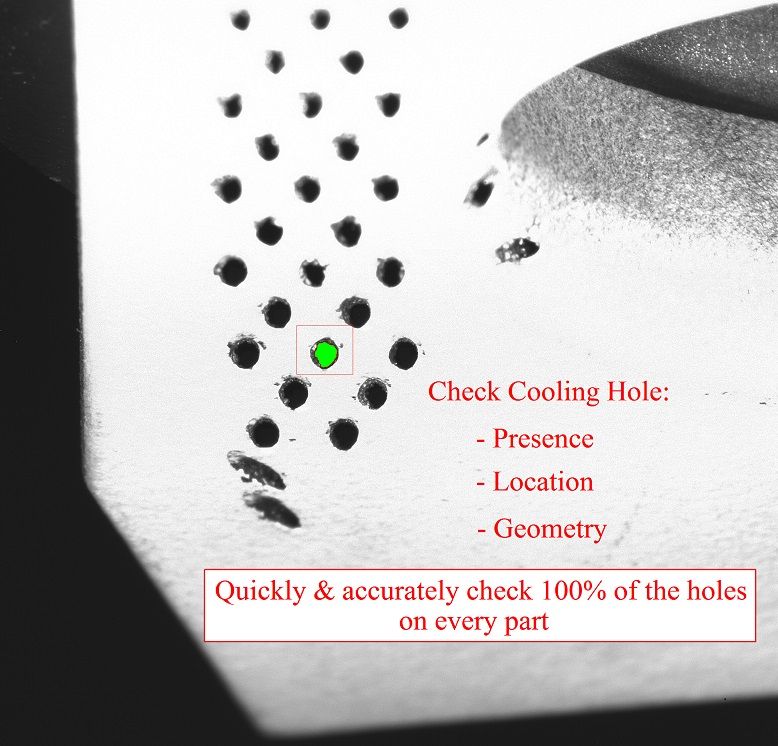

With all of this in mind, it’s easy to see the importance, during the manufacturing process, of ensuring that all the cooling holes are present and that their size, shape, location and orientation are correct, to allow them to properly play their critical role.

The 700 Series VisionGauge® Digital Optical Comparator is widely used by manufacturers across a broad range of industries (including aerospace and power generation) to inspect and measure EDM- and LASER-drilled cooling holes and slots.

The 700-series VisionGauge® Digital Optical Comparator is a very cost-effective, perfectly adapted solution for the measurement and inspection of cooling holes / EDM-drilled holes. It is rapidly becoming the new standard in the industry!

Download a .pdf version of this VisionGauge® Digital Optical Comparator Application Note here.