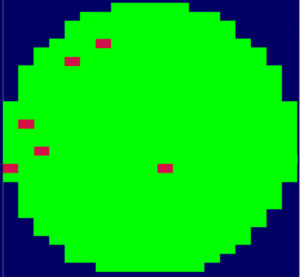

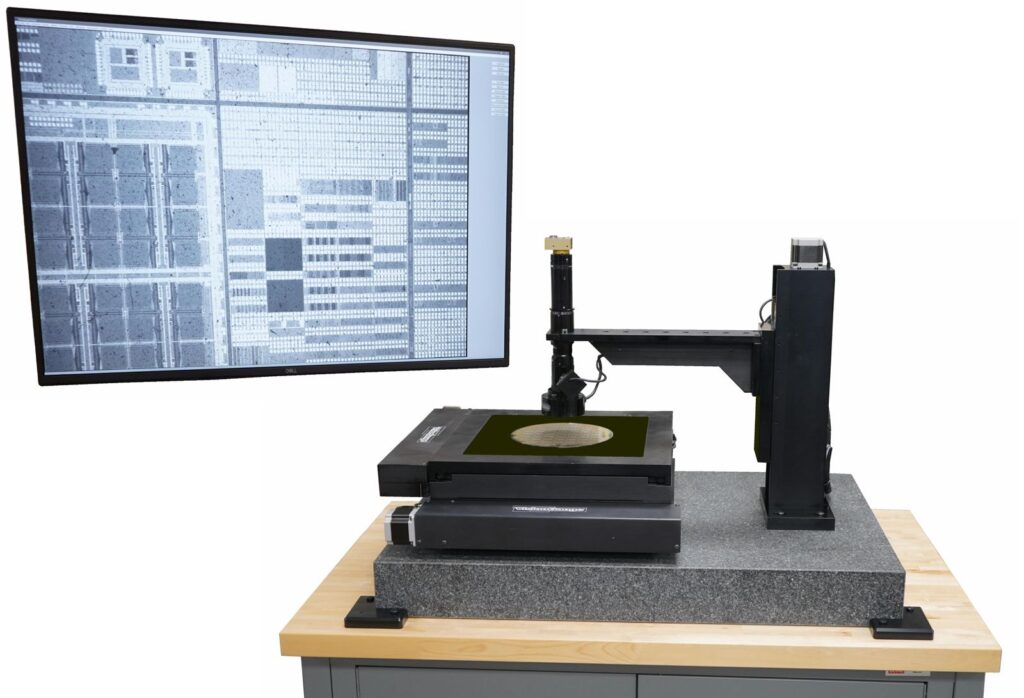

A customer recently provided a testimonial about a new VisionGauge® High-Accuracy Inspection and Measurement System they are using for automated semiconductor inspection. We released new enhancements to the Pass/Fail Data Group defect map used to quickly and conveniently review locations that failed inspection across parts.

Entegris purchased a VGHAIMS 12-12-4-1X tool primarily to perform dimensional verification of our photopatterned production components. Since installing the tool 6 months ago, it has met all of our requirements and reliability expectations, and we have discovered several additional valuable use cases and capabilities. More specifically, the tool identifies voids or missing material on some patterned parts, and it has also identified foreign material/residue (which would negatively impact performance of the finished good) on other parts.

The automated heatmaps of the inspected parts have proven extremely useful in identifying patterns of defects, and comparing part-to-part repeatability. The ability to drill-down (from the heatmap) to stored images of each field of view has been critical in verifying that actual defects are being reliably detected, and that false failures are not being counted. The ability to manually change the pass/fail rating (after review of the saved image) of each field of view is just one example of the user-friendly software.

Entegris is more than satisfied with system performance, and we consistently find the application support and customer service to be prompt, pleasant, and extremely knowledgeable/valuable.

Matthew Chriss

NPI Engineering Manager

Entegris, Inc.

Bedford, MA USA

Learn more about how VisionGauge® High-Accuracy Inspection and Measurement Systems are used in automated pattern verification and defect detection applications.