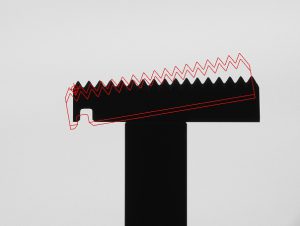

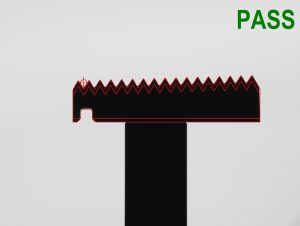

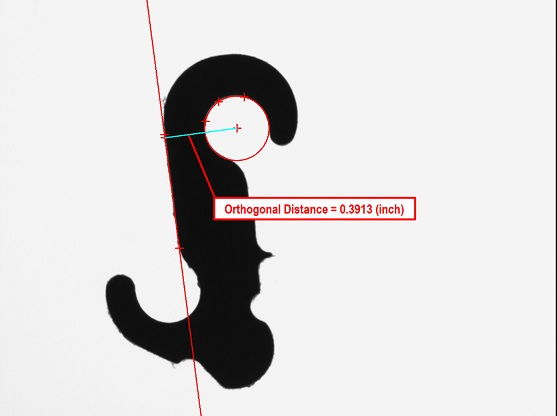

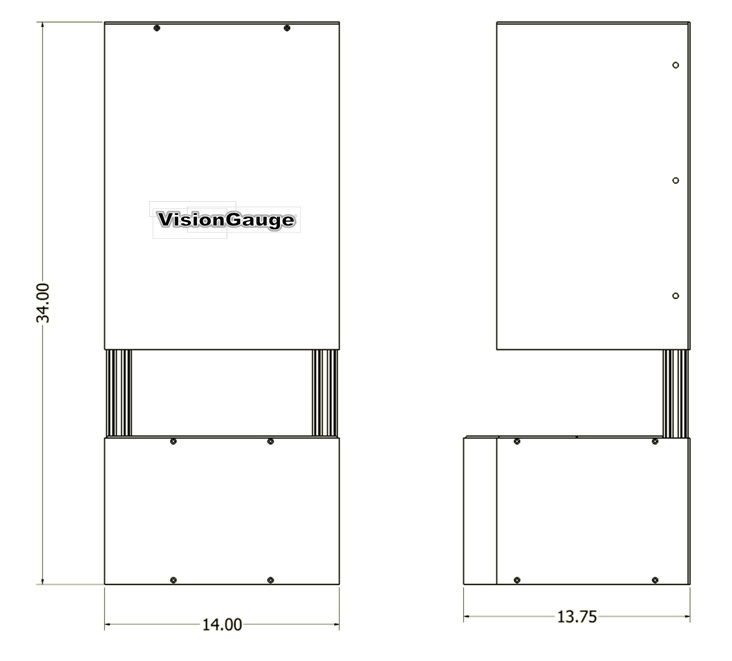

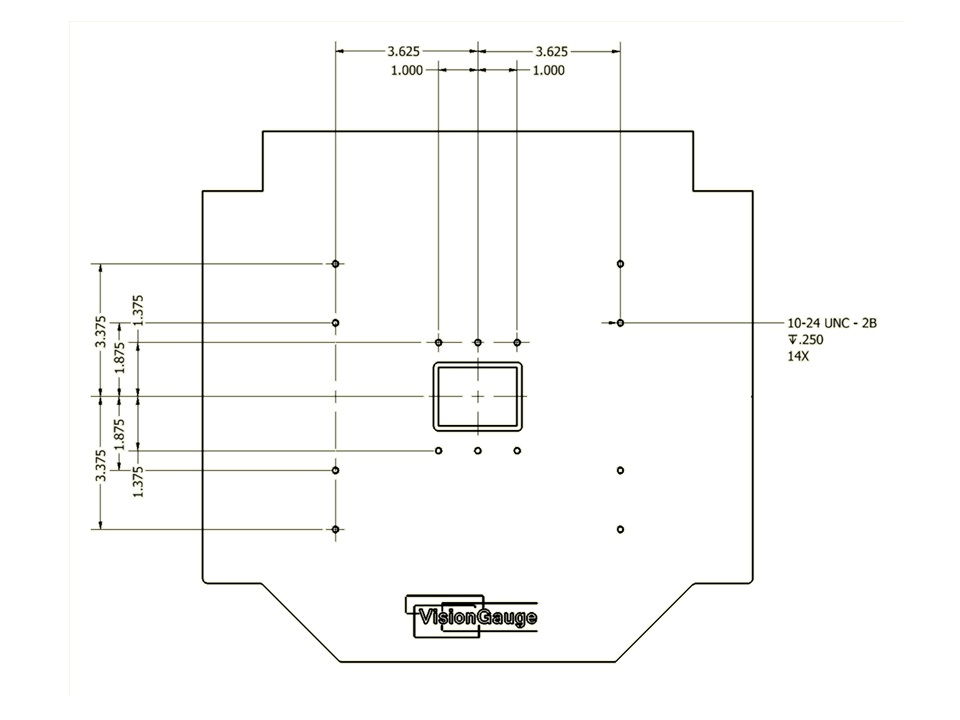

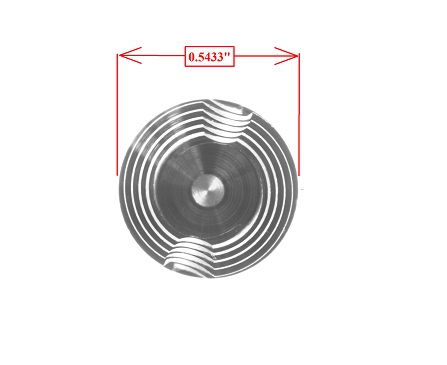

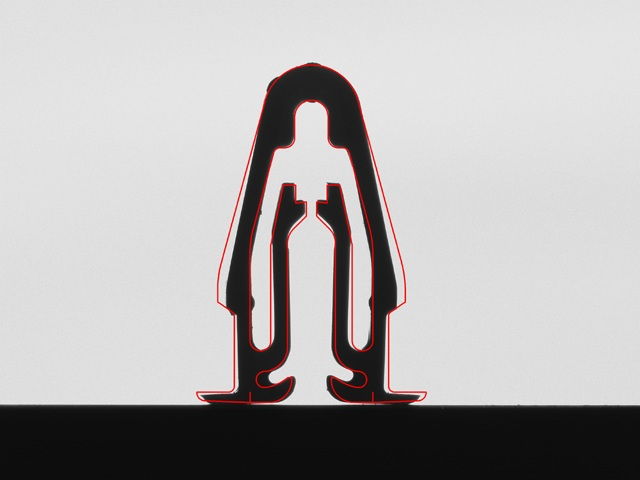

Checking, measuring, and inspecting small parts can be challenging — but not with the 300 Series VisionGauge® Digital Optical Comparator. Specially designed for inspecting small parts, this device offers the efficiency and convenience of other desktop optical comparators in a compact frame. Featuring VisionGauge® proprietary patented and patent-pending technology, this tool is a reliable partner for a comprehensive range of industrial applications. The digital functionality delivers precise measurements and innovative computations for a streamlined inspection process. Instant results and automated functions make it an ideal choice for high-throughput applications.

Request more information on devices in the VisionGauge® Digital Optical Comparator collection. Contact our experts for additional questions and system pricing.