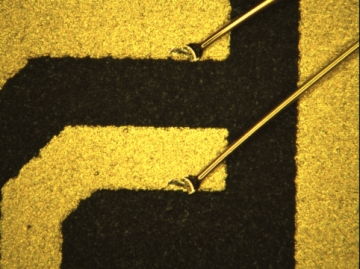

VisionGauge® High-Accuracy Field-Of-View Inspection & Measurement Systems are powerful, flexible, and extremely easy to use. They can be applied to solve a wide range of applications across many different industries.

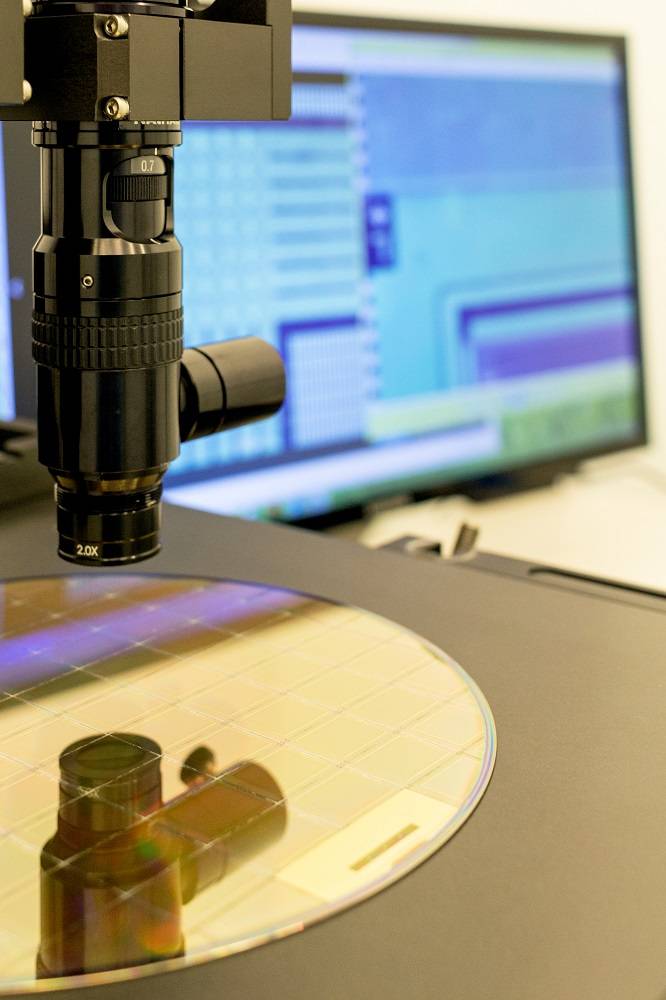

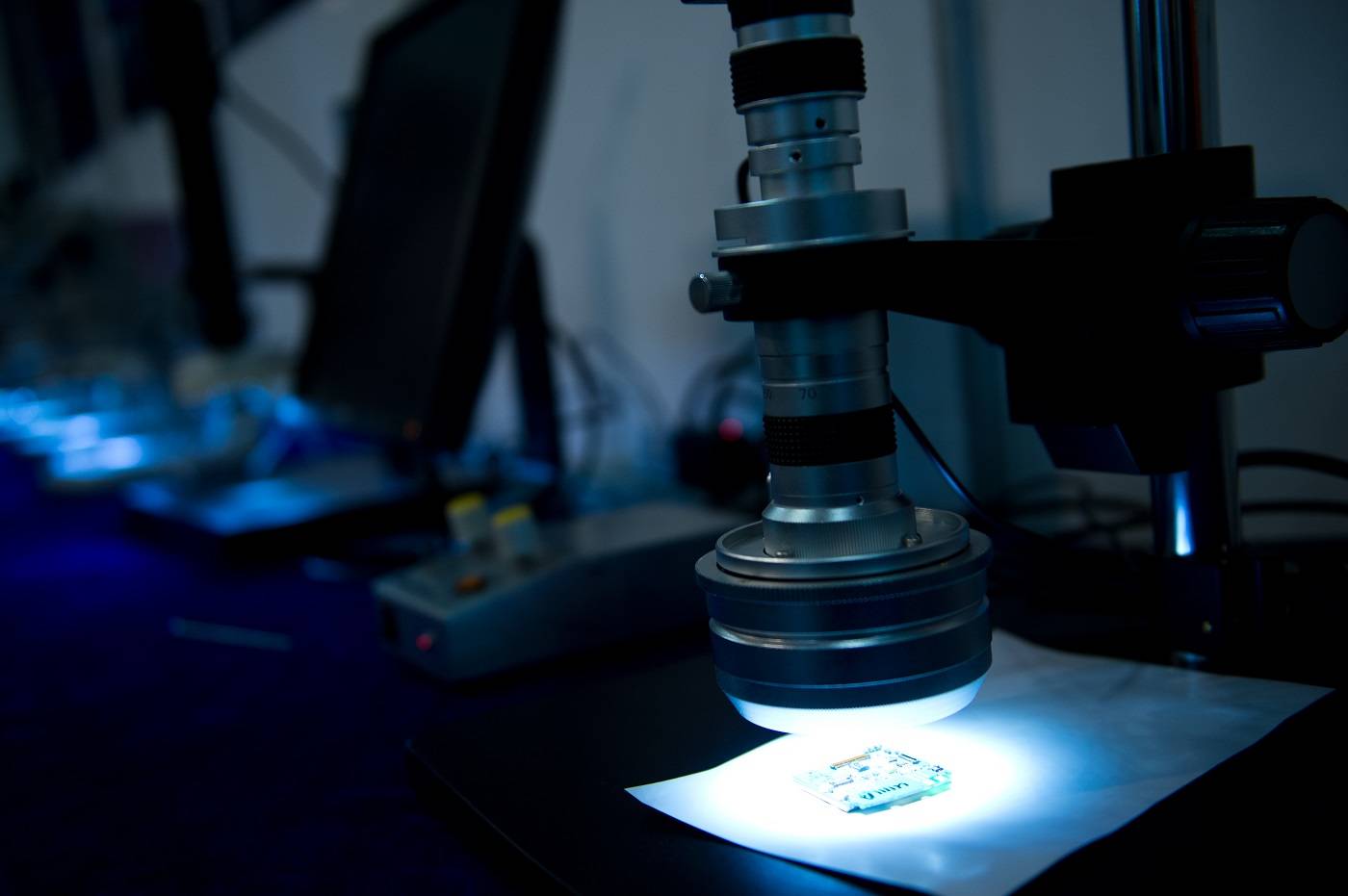

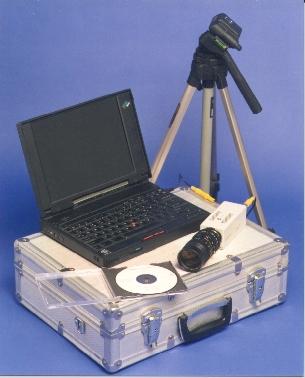

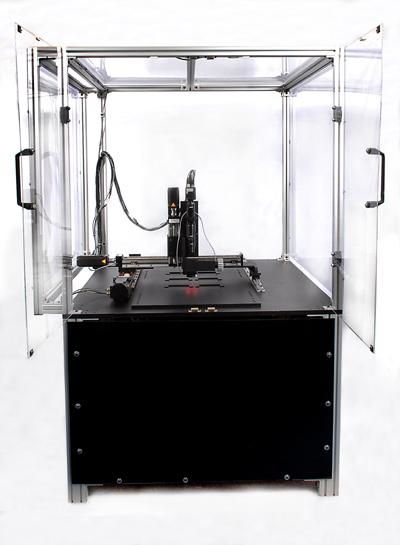

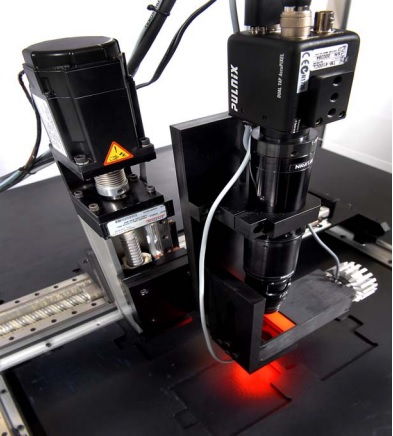

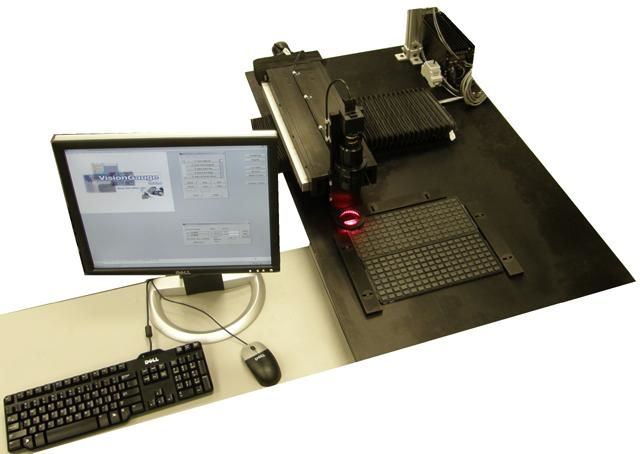

VisionGauge® High Accuracy Field-Of-View Inspection and Measurement Systems are available with either turret-based microscope type optics or with detented zoom optics. All of our industrial systems have a long working distance to provide ample clearance between the part and the lens.

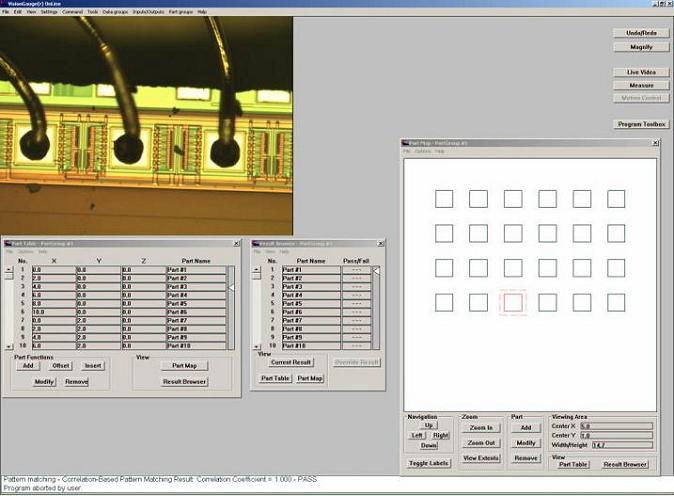

All our VisionGauge® High Accuracy Field-Of-View Inspection and Measurement Systems run the VisionGauge® software package:

- Powerful and easy-to-use

- Includes all of VisionGauge®’s advanced patented tools & technologies (for high-accuracy automated part-to-CAD comparison, operator-independent results, etc…)

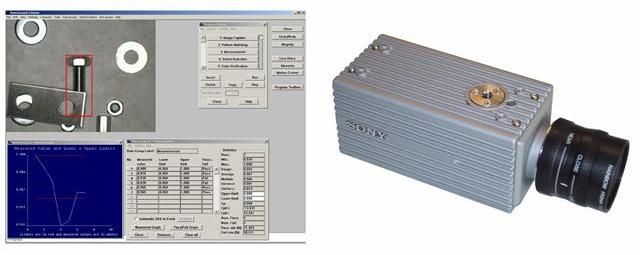

- Includes a wide range of powerful inspection and sub-pixel accurate measurement tools

- VisionGauge® software allows for easy data collection, statistics (with graphs & charts), reporting as well as data transmission & exchange

- Supervisor-level / operator-level password protection

- Robust & field-proven, with a broad installed base (over 3500 licenses in use worldwide)

These network-ready Windows™-based systems are appropriate for both the shop floor and the QC lab.

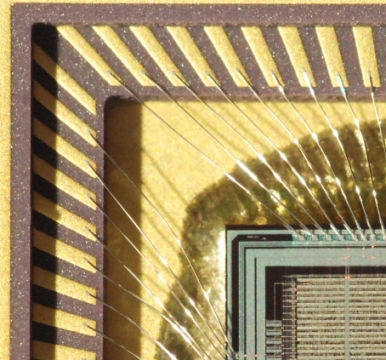

VisionGauge® High Accuracy Field-Of-View Inspection and Measurement Systems are perfect for wide range of industrial production, quality control, and laboratory applications.

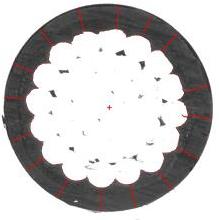

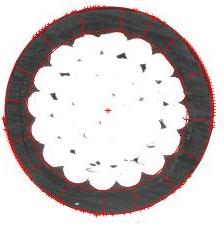

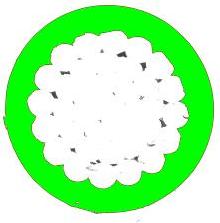

VisionGauge®’s advanced edge-detection technology produces sub-pixel accurate measurements, increases measurement repeatability, and eliminates operator-dependent measurement error. Standard configurations are available off-the-shelf and non-standard configurations can also be accommodated. We can configure a system to meet your specific requirements!

These inspection and measurement systems are built around the powerful and easy-to-use VisionGauge® software package, which means that they have a simple and intuitive Windows™ interface and include a wide range of fully-integrated tools for imaging, measurements, statistics, databasing, reporting (with charts & graphs), data transmission & exchange, and much, much more!

VisionGauge® 3D inspection & measurement systems also include a wide range of image analysis and measurement tools to allow you to successfully solve a wide range of applications. VisionGauge®’s powerful stage-based vision inspection tools include counting and sizing (blob analysis), registration and alignment, measurement, pattern matching, illumination control, color verification, defect detection, and many others.

Contact us with the details of your application and for more information.

Learn more about the various industries and applications using our VisionGauge® inspection and measurement systems.