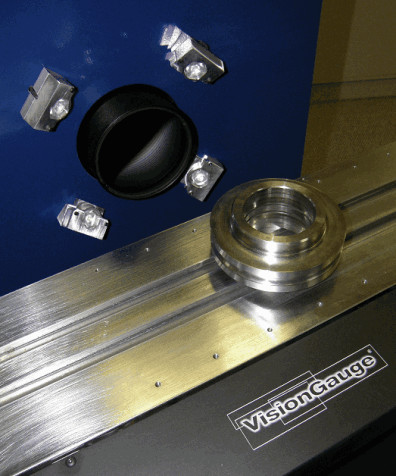

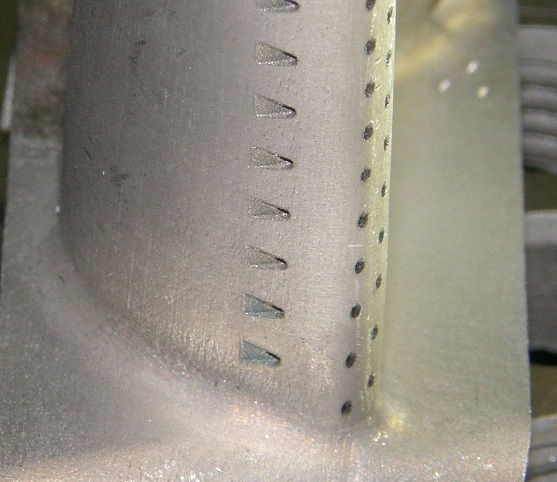

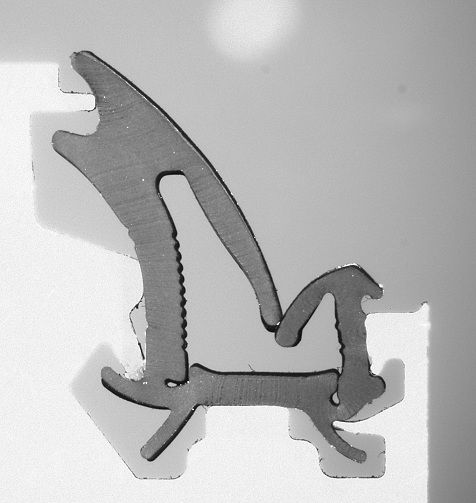

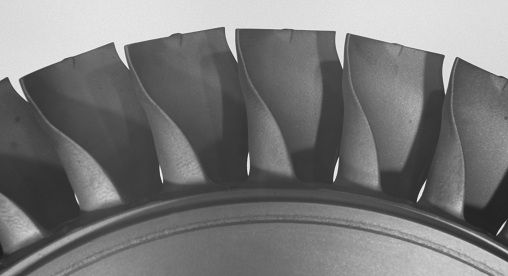

VisionGauge® Digital Optical Comparators are the ideal solution for the inspection and measurement of Thread Rolling Dies

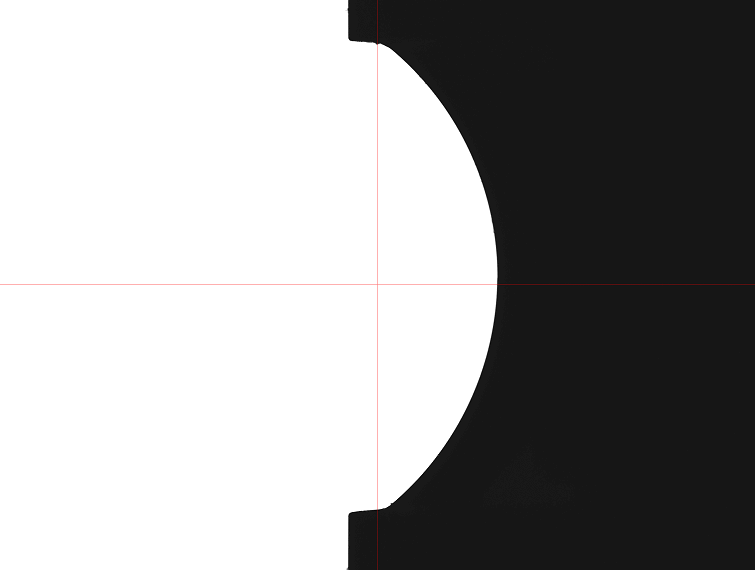

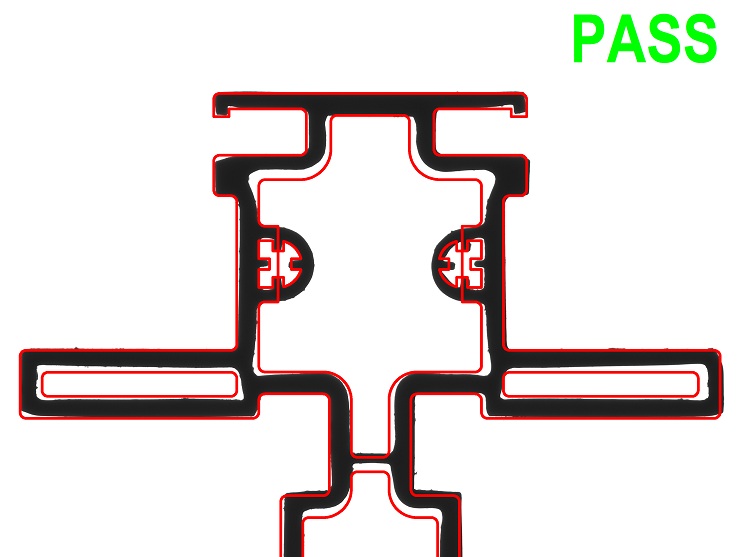

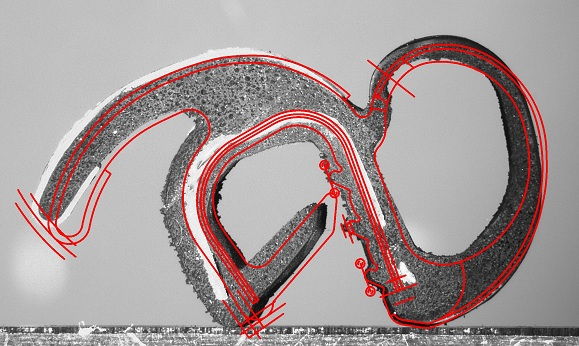

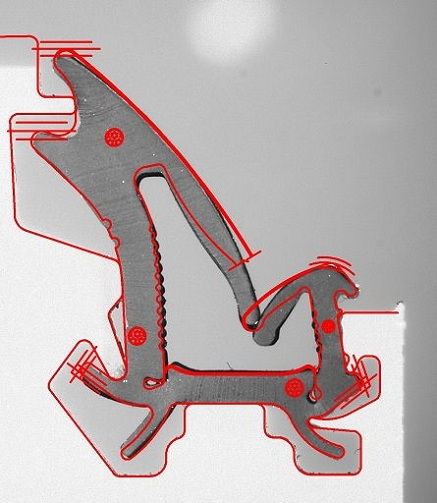

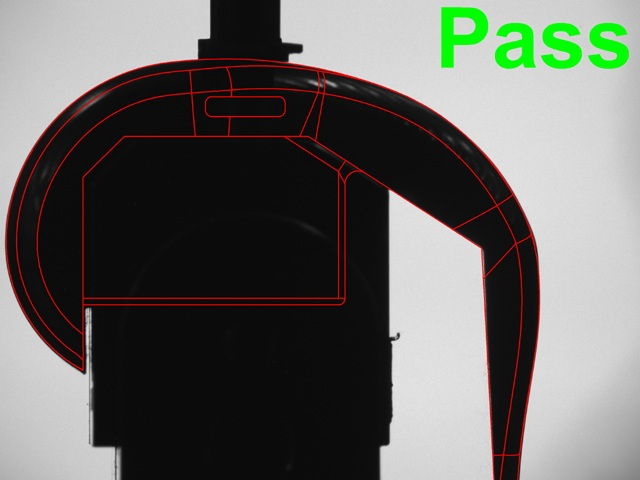

- Compare thread rolling dies directly to their CAD data 100% automatically (no need for overlays!).

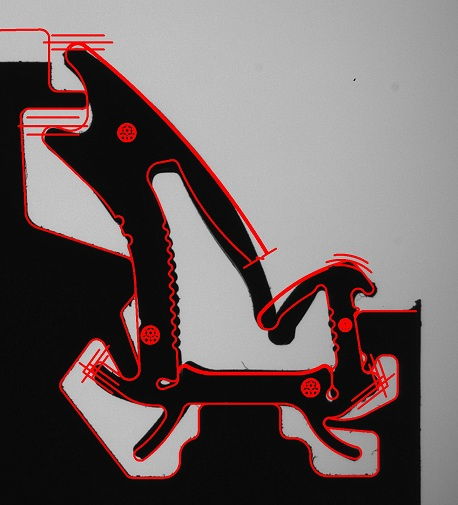

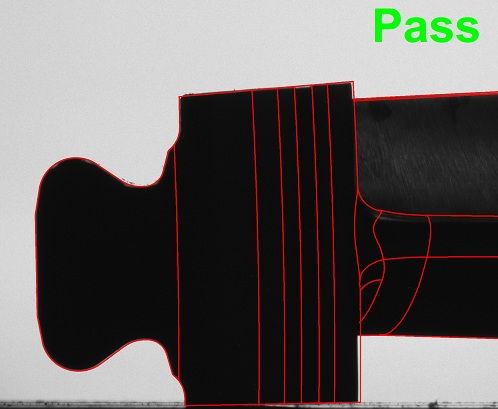

- The VisionGauge® Digital Optical Comparator’s proprietary CAD Auto-Align™ tool aligns a CAD/DXF drawing straight to its part, with customizable options to produce the best results.

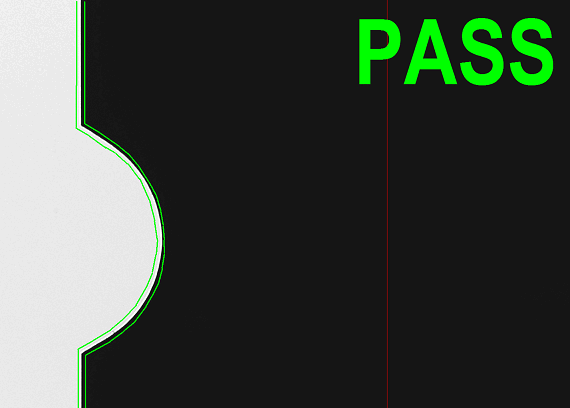

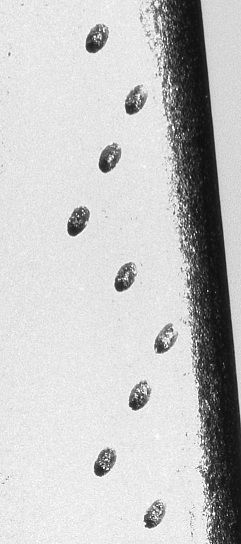

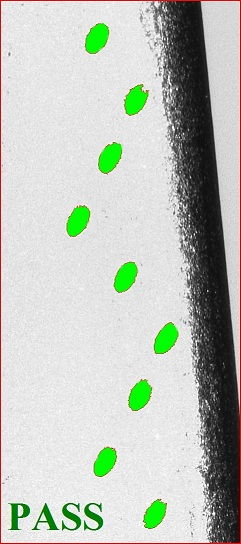

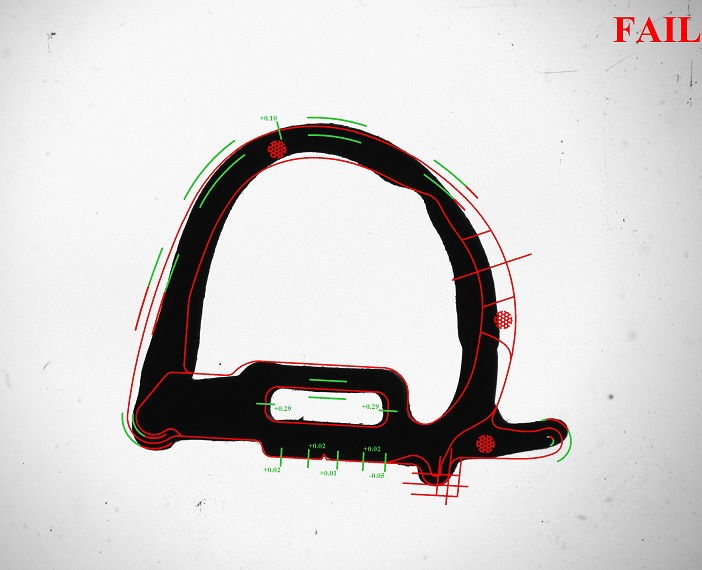

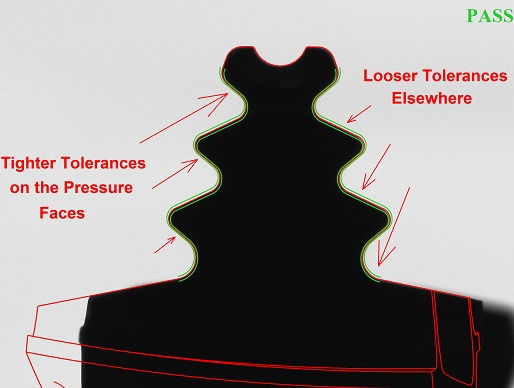

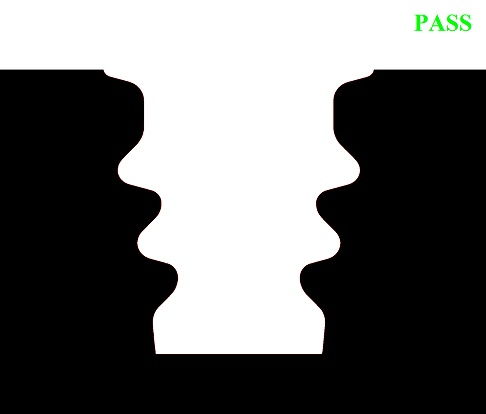

- The CAD Auto-Pass/Fail™ tool produces an operator-independent PASS/FAIL result, completely automatically.

- Accurate and repeatable inspections directly on the shop floor!

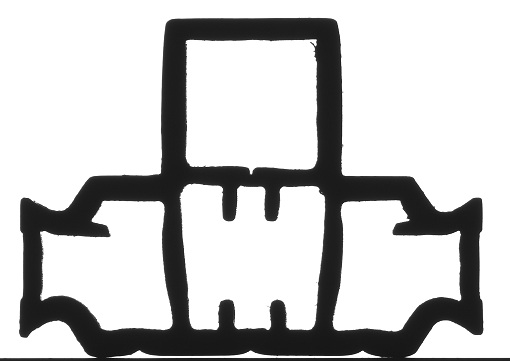

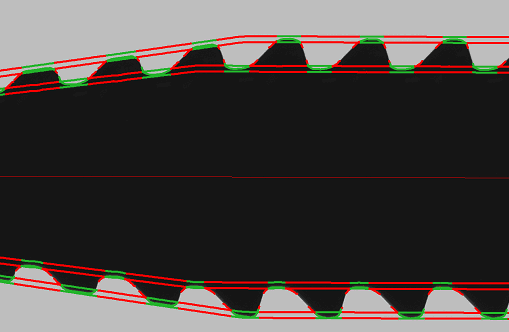

- All part geometries are supported – the possibilities are limitless!

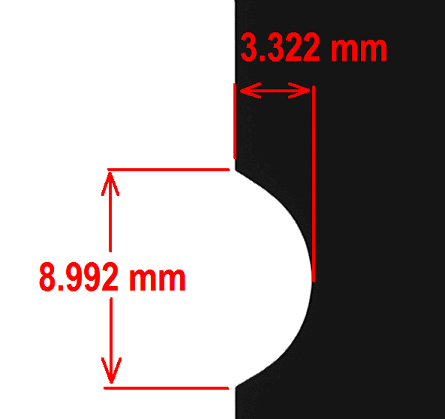

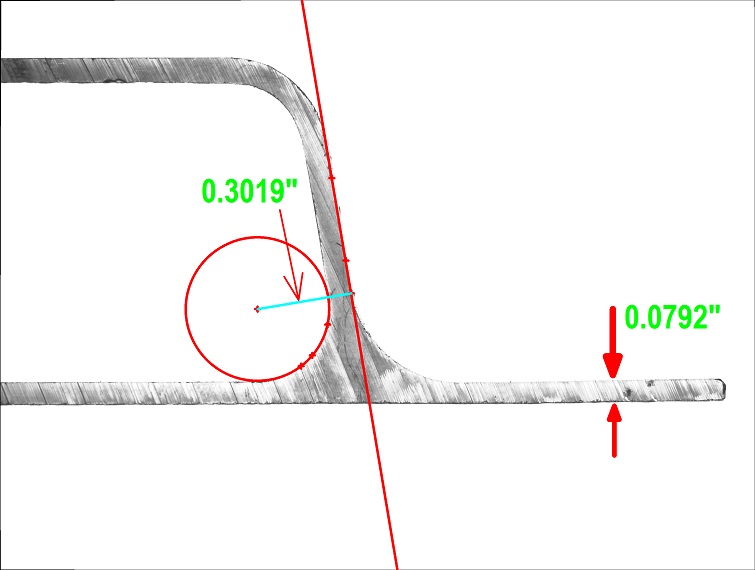

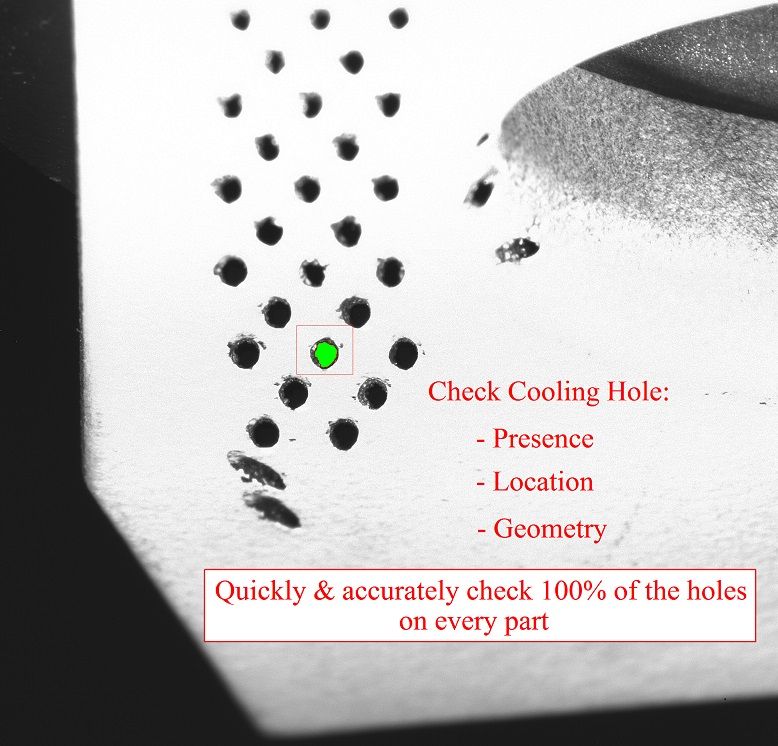

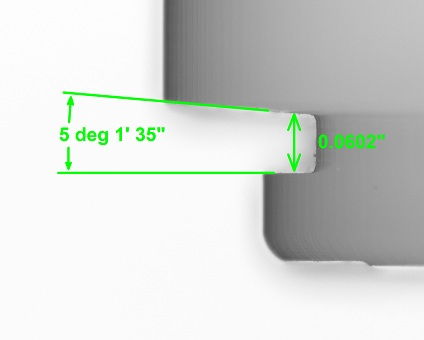

- The system can automatically locate and check the features of interest according to your specifications.

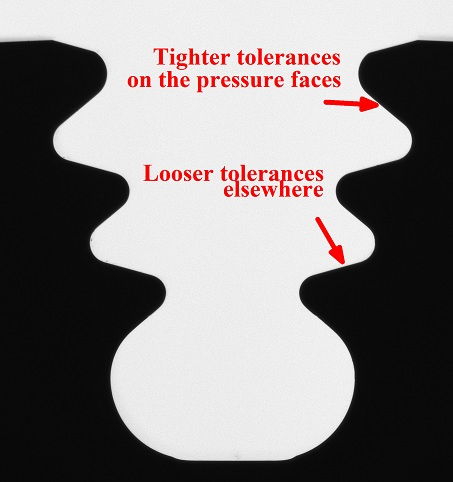

- VisionGauge® Digital Optical Comparators support variable tolerances. Tighter tolerances can be applied in critical areas and looser tolerances elsewhere.

- The system automatically measures a part’s deviations from nominal at critical points or along entire segments of the part’s edges. Edges that lie outside of the defined tolerance band are quickly located and displayed.

- Automated collection of measurements, statistics, images, and other data for complete documentation.

- Obtain faster, more accurate, and more reliable results than when using traditional inspection methods and systems.

- The system is extremely to use: It can be setup so that – for the operator – everything is done using the barcode reader.

VisionGauge® Digital Optical Comparators are well-adapted to surmount the complications of thread rolling die inspection and measurement, improving the quality of your inspection process and results.

VisionGauge® Digital Optical Comparators are the new standard for obtaining fast, accurate, and high-quality inspections in the thread rolling die industry. Contact us for more information about how our systems and software can solve your application.

Download a .pdf version of this VisionGauge® Digital Optical Comparator Application Note. Also, learn more about additional applications solved using VisionGauge® Digital Optical Comparators and Profile Projectors.