Inspection & Measurement of Orthopedic Implants

The Ideal Solution for Orthopedic Implant Inspection (including knees, hips, plates, shoulders, and many more)

Performing a quality inspection on orthopedic implants presents a number of challenges. There are a wide variety of implant sizes and shapes, and they have complex geometries that require tight tolerances. 100% inspection is a necessity and it is unacceptable to miss even one defect. It is common for implants to be manufactured in small lots so there is very high product changeover. Therefore, it is very advantageous that product inspection takes place directly on the production floor. And if any programming is required on the quality inspection system, it needs to be fast, easy, and as error-free as possible.

The VisionGauge® Digital Optical Comparator was originally developed with extensive collaboration with a large medical OEM to meet the requirements of orthopedic implant measurement and inspection, so this inspection is one of their ideal applications.

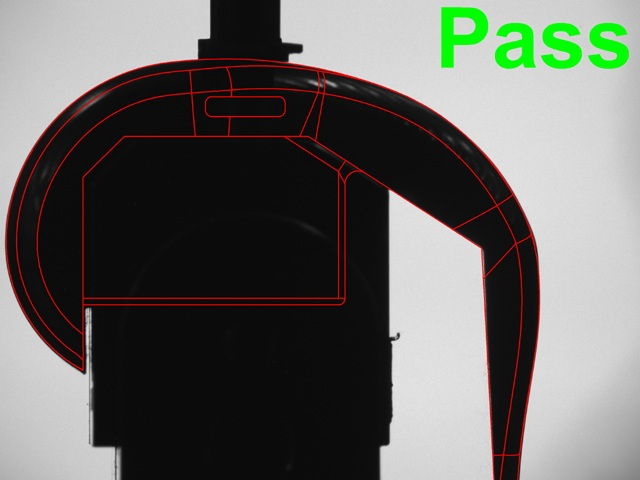

These systems are accurate, very fast, and require minimal to no programming. The system can operate directly on the shop floor and can produce automated inspection reports and gather complete device history: Collect images, Pass/Fail results, measurements, statistics with graphs/charts and output all data from an inspection to a centralized database. Unique and patented tools like CAD Auto-Align™ and CAD Auto-Pass/Fail™ efficiently and automatically compare a part directly to its CAD file to very high accuracy, automatically and completely without operator variation or subjectivity. These systems are successful on a broad range of applications. The VisionGauge® Digital Optical Comparator has no limitations to part geometry and a wide range of implants are easily supported, including both metal and plastic.

There are many reasons why VisionGauge® Digital Optical Comparators are employed by orthopedic implants manufacturers to inspect and measure the medical implants and devices they produce:

- Compare products directly to their CAD data, completely automatically (no more overlays or Mylars!)

- VisionGauge®'s patented CAD Auto-Align™ and CAD Auto-Pass/Fail™ tools are easy to use to automatically inspect and measure parts, and they produce very high-accuracy results.

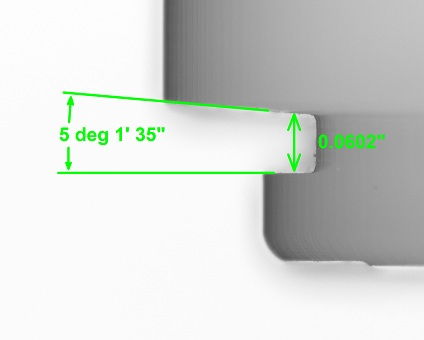

- Accuracy down to +/-0.0001" demonstrated in real-world applications, directly from the shop floor!

- VisionGauge® Digital Optical Comparators are proven faster and allow for significant gains in throughput compared to traditional comparators.

- Results are 100% consistent between users - No more variation from operator to operator!

- Automated programs can be stored and recalled per part as needed or the system can be used in manual mode - either way, the system is especially well suited for inspecting small lots with rapid part changeover.

- The systems provide multiple options for complete documentation and reporting of statistics, measurements, images, and other data.

- The system's extended optical depth-of-field and Auto-Focus tool easily overcome the difficulties of orthopedic implant inspection.

- Make defects truly stand out and entirely remove glare with multiple options for adapted computer-controlled LED illumination. VisionGauge® Digital Optical Comparators produce stunning results on both metal and plastic parts!

- Automatically measure and display deviations from nominal: Quickly and easily locate areas out of tolerance.

- VisionGauge® Digital Optical Comparators are not limited to performing inspections only in the camera's field-of-view: A part can be compared to its CAD/DXF data across the entire stage travel. Check large and long parts at high magnification and very fine resolution with ease.

VisionGauge® Digital Optical Comparators are perfect to inspect a wide range of orthopedic implants and devices: knees, hips, plates, shoulders, and many more...

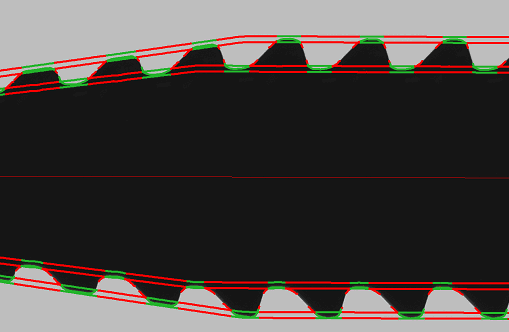

With its patent pending Tooth Checker™ tool the VisionGauge® Digital Optical Comparator is perfect for inspecting medical bone screws

The systems are also widely used in the inspection of forgings.

The VisionGauge® Digital Optical Comparator is the new standard for inspecting orthopedic implants in the medical industry. Contact us to find out how we can solve your application.

Download a .pdf version of this VisionGauge® Digital Optical Comparator Application note here. Learn more about other inspection and measurement applications solved by our systems. A press release from November 2023 is also available.