Cooling Holes Inspection / Cooling Hole Measurement and Verification

The 700-Series VisionGauge® Digital Optical Comparator is the Perfect Solution for EDM- and LASER-Drilled Holes and Slots Inspection and Measurement

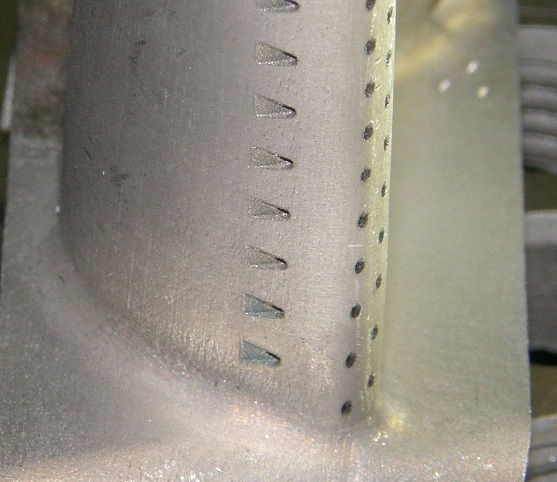

In modern aircraft engines and industrial gas turbines (IGT) combustor exit gas temperatures exceed the melting point of the turbine engine materials. Running hotter enables engines to maximize efficiency and minimize fuel consumption. To protect the engine components that are subjected to these too-high temperatures, patterns of small holes – called cooling holes – are strategically placed to allow (relatively) cooler air to be injected and form a thin protective layer over the material surface. Without this protective film of cooler air, of the engine components subjected to the highest temperatures would literally melt, leading inevitably to catastrophic engine failure.

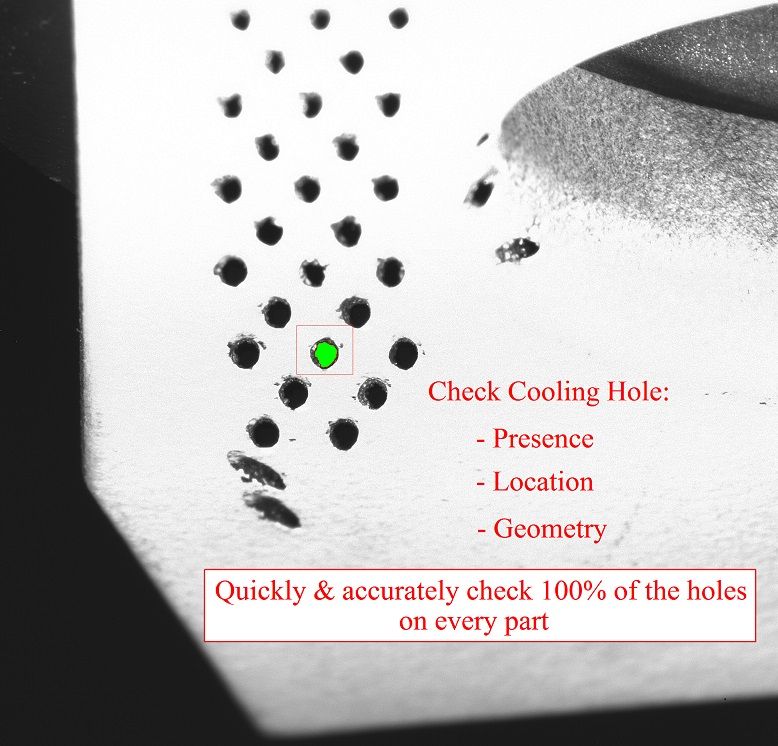

With all of this in mind, it’s easy to see the importance, during the manufacturing process, of ensuring that all the cooling holes are present and that their size, shape, location and orientation are correct, to allow them to properly play their critical role.

The 700 Series VisionGauge® Digital Optical Comparator is widely used by manufacturers across a broad range of industries (including aerospace and power generation) to inspect and measure EDM- and LASER-drilled cooling holes and slots.

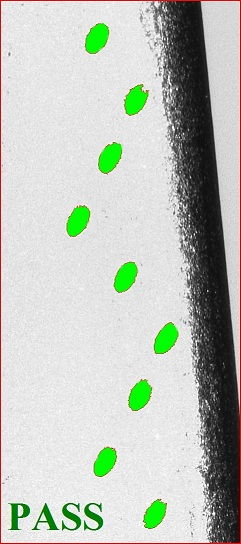

- Automatically verify hole presence & accurately measure hole location

- Supports both round and shaped holes

- 5 axes of motion (X, Y, Z, Rotary, Tilt) to properly view parts from all sides & angles

- Quickly, easily, and accurately inspect 100% of the holes on your parts

- Robust shop floor design

- Can output the hole offsets which can be used to modify EDM drilling programs

- Mounting system allows your parts to go directly from the EDM drilling machine to the inspection and measurement system without re-fixturing (quick & easy and also minimizes stack-up error, etc...)

- The system can be supplied with the same working envelope as your EDM drill. If you can drill it, we can check it!

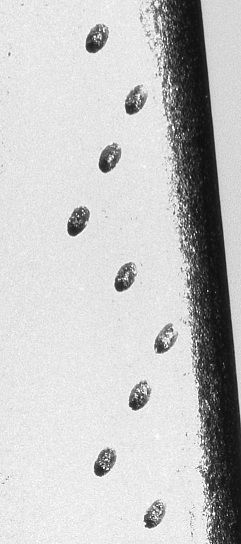

- Holes can be checked either one at a time, looking straight down each hole's nominal axis (ideal for coated parts, to minimize errors due to coating thickness variations) or multiple holes can be checked at once, viewing them at an angle (which is even faster and well suited for uncoated parts or parts with a uniform coating thickness)

- The system has an extended depth of field, so that everything is perfectly in focus regardless of the part's geometry (even in areas of very high curvature) as well as a very long working distance (so that there is lots of clearance between the part and the entire optical system to comfortably accommodate large and unusually-shaped parts)

- Extremely powerful "adaptive" feature-detection software tools are able to accurately find and locate EDM-drilled holes on different surfaces, with different reflectivity, at different viewing angles, etc.

- Specialized software tools are especially well suited to deal with burrs and splatter

- Automatically create reports and collect measurements, statistics, images and other data for complete documentation

- Fast and intuitive "operator review" mode allows the operator to quickly revisit out-of-tolerance areas, etc.

- The ideal system for inspection and measurement of cooling holes on aircraft engine and IGT (Industrial Gas Turbine) components (blades, vanes, heat shields, shrouds, etc.). Parts can be either (ceramic) coated or uncoated.

Automatically Verify Hole Presence and Location

Supports Both Round & Shaped Holes, Anywhere on the Part!

An extended-travel machine with 24" x 24" x 24" travel and a trunnion configuration for large and heavy parts is also available, along with other customizations.

The 700-series VisionGauge® Digital Optical Comparator is a very cost-effective, perfectly adapted solution for the measurement and inspection of cooling holes / EDM-drilled holes. It is rapidly becoming the new standard in the industry!

Download a .pdf version of this VisionGauge® Digital Optical Comparator Application Note here.